5

5 INSTALLATION: FIXATION

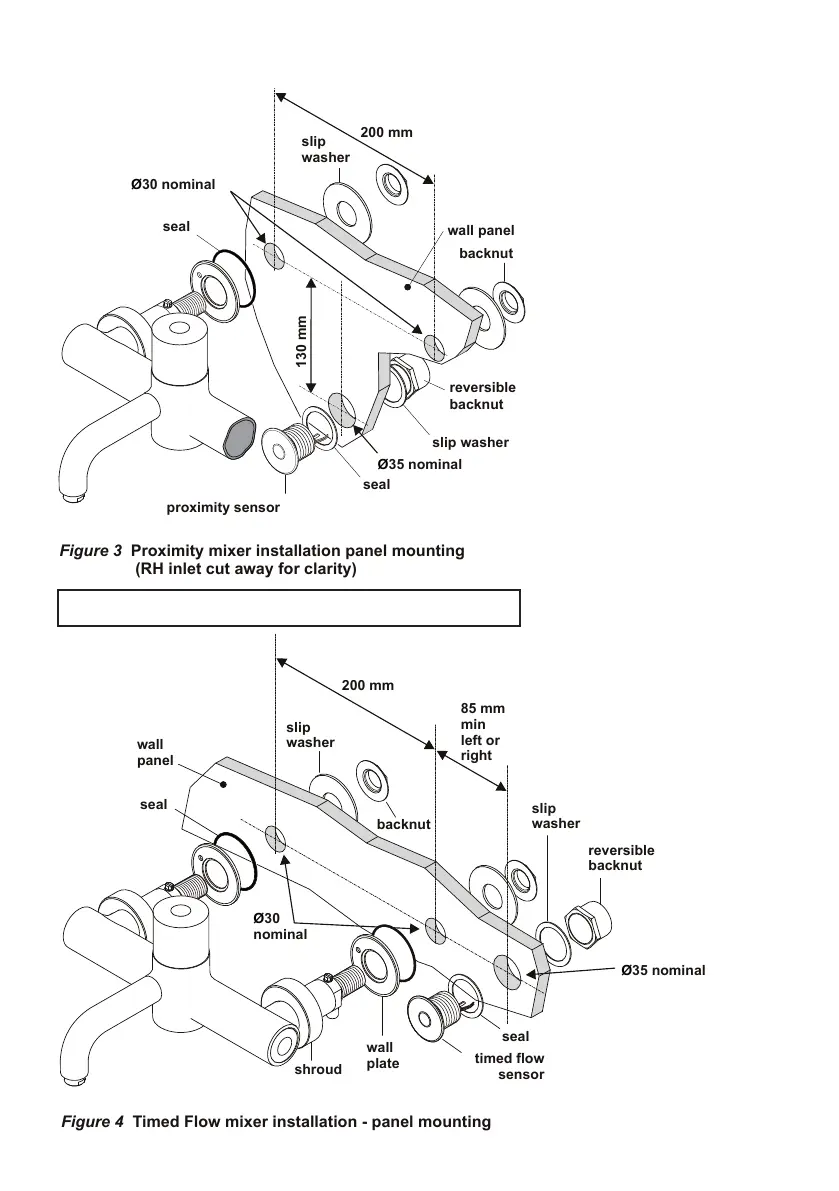

Proximity mixer installation panel mounting

(RH inlet cut away for clarity)

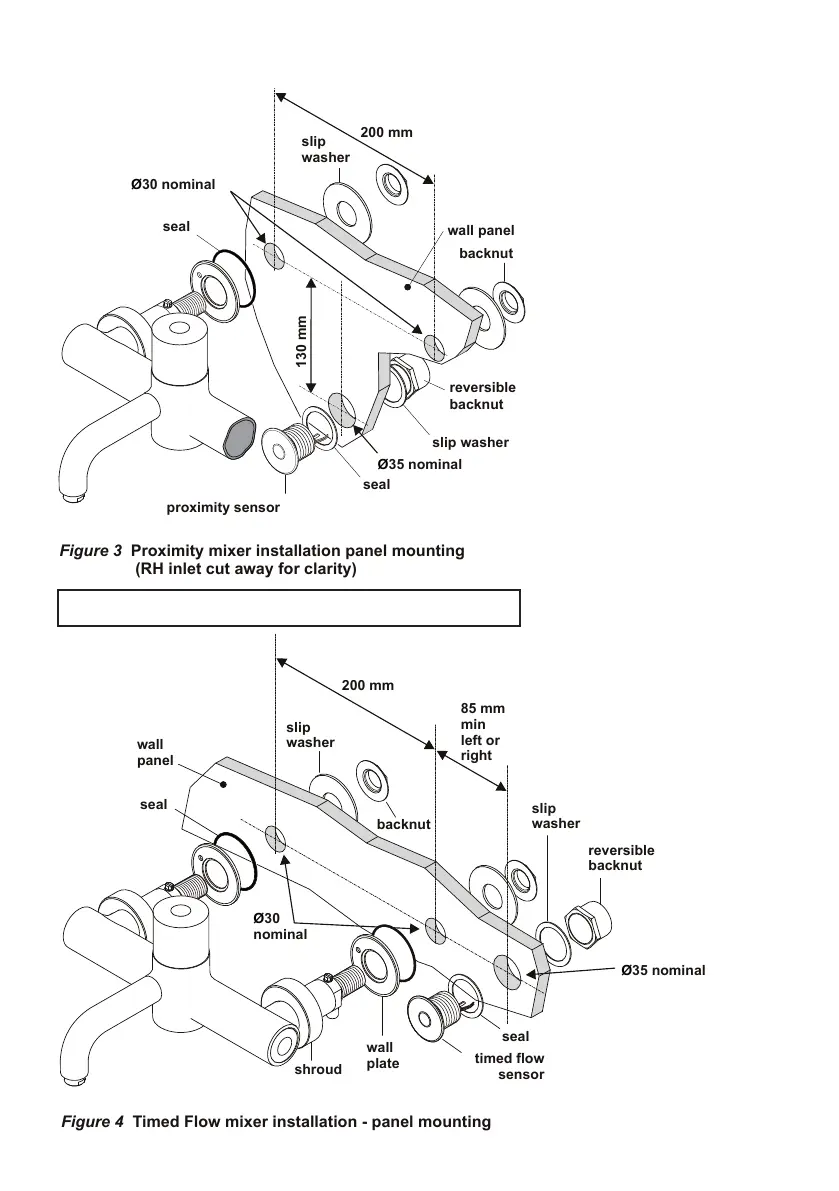

installation - panel mounting

These mixers are designed to be

panel mounted on a duct wall of

maximum panel thickness 27mm.

For thicker panels the rear of the

panel will require counter bores of

62mm or greater around the xa-

tion holes.

Cut two holes of 30mm diameter,

horizontally aligned to 200mm

centres in the wall.(See figure 1

for height positioning of the tting

body over a “waste appliance”)

The sensor will require a hole of

35mm positioned as indicated in

either g1 or g2.

Loosen the chrome shrouds and

insert the tting as shown above

with the wall plates and seals to

the front of the wall.

Put on the slip washers and do up

the backnuts to a torque of 25 Nm

.

Screw the shrouds onto the

wall plates.

Check that all joints are securely tightened, test for leaks.

Loading...

Loading...