6

6 INSTALLATION: PLUMBING

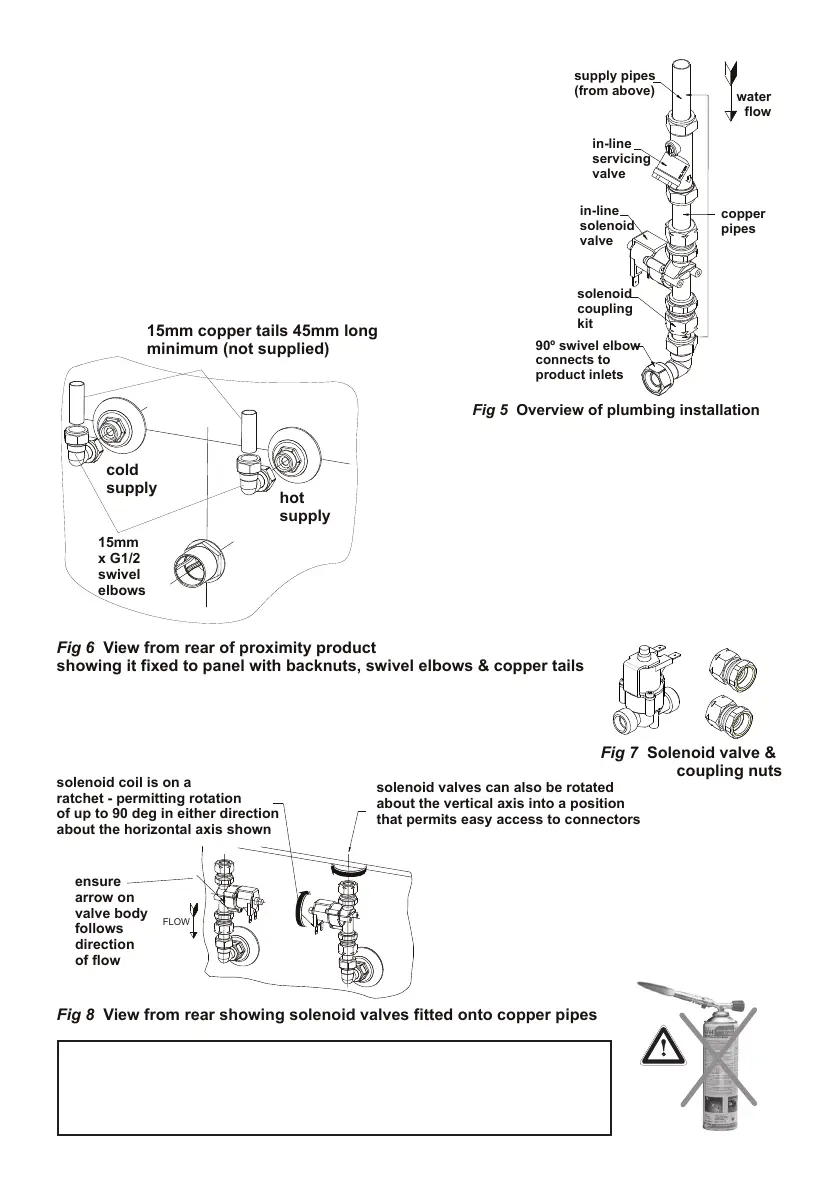

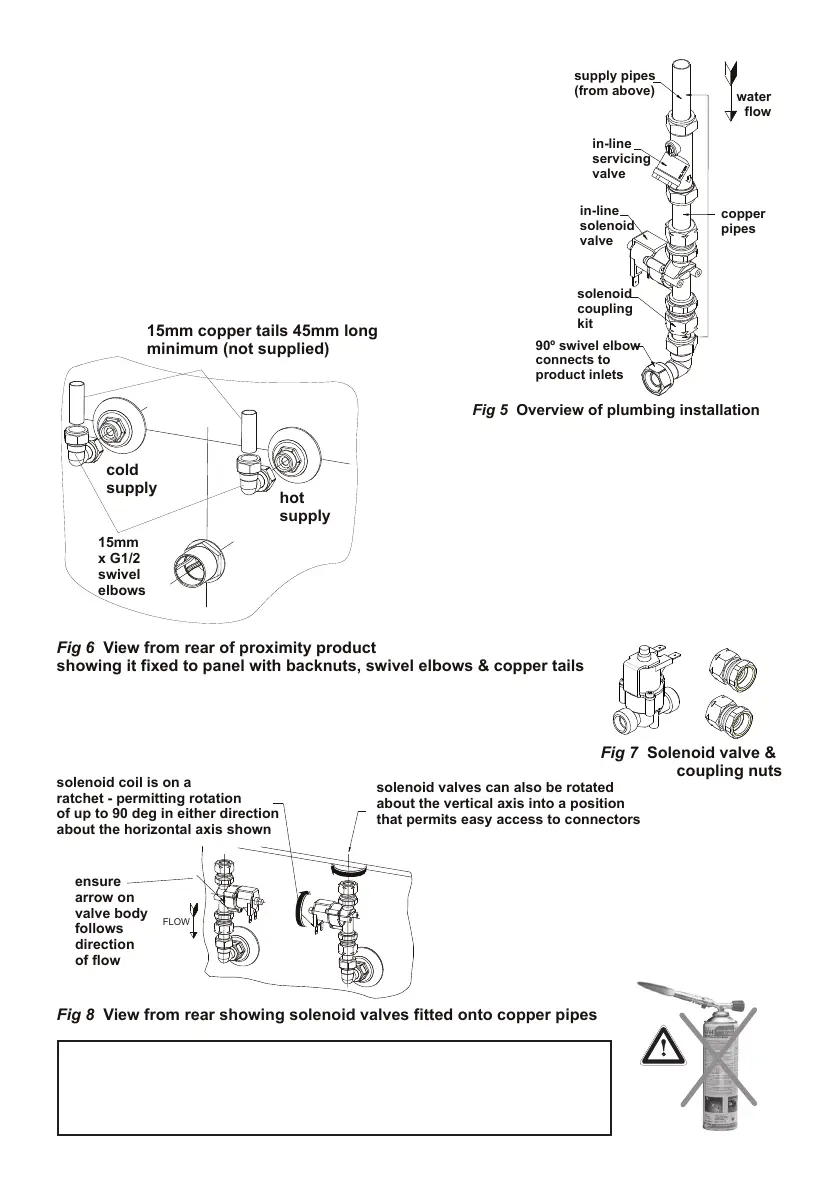

Fig 5 Overview of plumbing installation

Fig 6 View from rear of proximity product

showing it fixed to panel with backnuts, swivel elbows & copper tails

Fig 8 View from rear showing solenoid valves fitted onto copper pipes

15mm copper tails 45mm long

ratchet - permitting rotation

of up to 90 deg in either direction

about the horizontal axis shown

solenoid valves can also be rotated

about the vertical axis into a position

that permits easy access to connectors

First refer to section 4. Supply conditions.

A typical example of an installation of a proximity mixer is shown

here as a guide. In this example, the water supply pipes are pro-

vided from above (this usually permits better drain down of pipes).

Supplies can be from any direction.

This diagram shows the preferred method of assembling the plumb-

ing components. Two of these assemblies are required per product.

OBSERVE ARROWS ON VALVE BODIES.

IMPORTANT: Avoid using heat for soldering near the product

inlets to prevent damage to internal components

Mount mixer to the panel and secure the backnuts.

Fit swivel elbows (15mm x G1/2, not supplied) to the inlet tails

as shown and ensure the seals supplied with them are tted

between the inlet tails & the elbows. Make good the joints.

Prepare two short lengths of 15mm copper pipe (minimum

of 45mm long) and assemble to the compression side of

elbows. Make good the joints

IMPORTANT: When viewed from the REAR, the HOT

supply should be connected to the RIGHT hand side.

The coupling nuts (supplied) can now be screwed onto both sides of

both in-line solenoid valves. Ensure the seals provided are tted be-

tween the solenoids and the coupling nuts. Make good the joints, taking

care not to use excessive force.

The solenoid valve assemblies can now

be loosely tted onto the copper pipes.

IMPORTANT: Ensure directional ar-

row onvalve body follows the direc-

tion of the water ow.

Position solenoid valves as required and

then make good the joints

DO NOT apply heat near this product. Heat generated by soldering

could damage plastic parts and seals.

Check that all joints are securely tightened, test for leaks.

Loading...

Loading...