Do you have a question about the Armstrong Design Envelope 4300 and is the answer not in the manual?

General safety advice and precautions for installation and operation, covering safe use, temperature, enclosure, noise, vibration, storage, warranty, uncrating, and handling.

Electrical safety precautions, including ambient temperature limits and qualified electrician requirements.

Diagram illustrating all electrical and control connections.

Essential checks to perform before putting the pump into operation.

Procedure for safely starting the pump, including priming, valve operation, and auto flow balancing.

How to view and acknowledge alarms and warnings on the interface.

Control based on a curve between max/min flow, replicating sensorless operation.

Quadratic control with a feature to maintain minimum flow for equipment stability.

Quadratic control to maintain maximum flow, preventing over-pumping and saving energy.

Enables staging of multiple pumps to meet flow requirements efficiently.

Detailed steps for replacing mechanical seals on 4300 Split Coupled pumps.

Detailed steps for replacing mechanical seals on 4380 Close Coupled pumps.

Lists and describes common alarm conditions for the VSD and pump.

Tables providing recommended fuse sizes and circuit breaker ratings for various voltage and enclosure types.

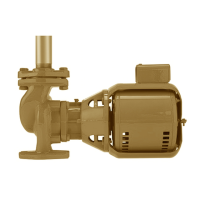

| Brand | Armstrong |

|---|---|

| Model | Design Envelope 4300 |

| Category | Water Pump |

| Language | English |