# 45465K005

Page 6

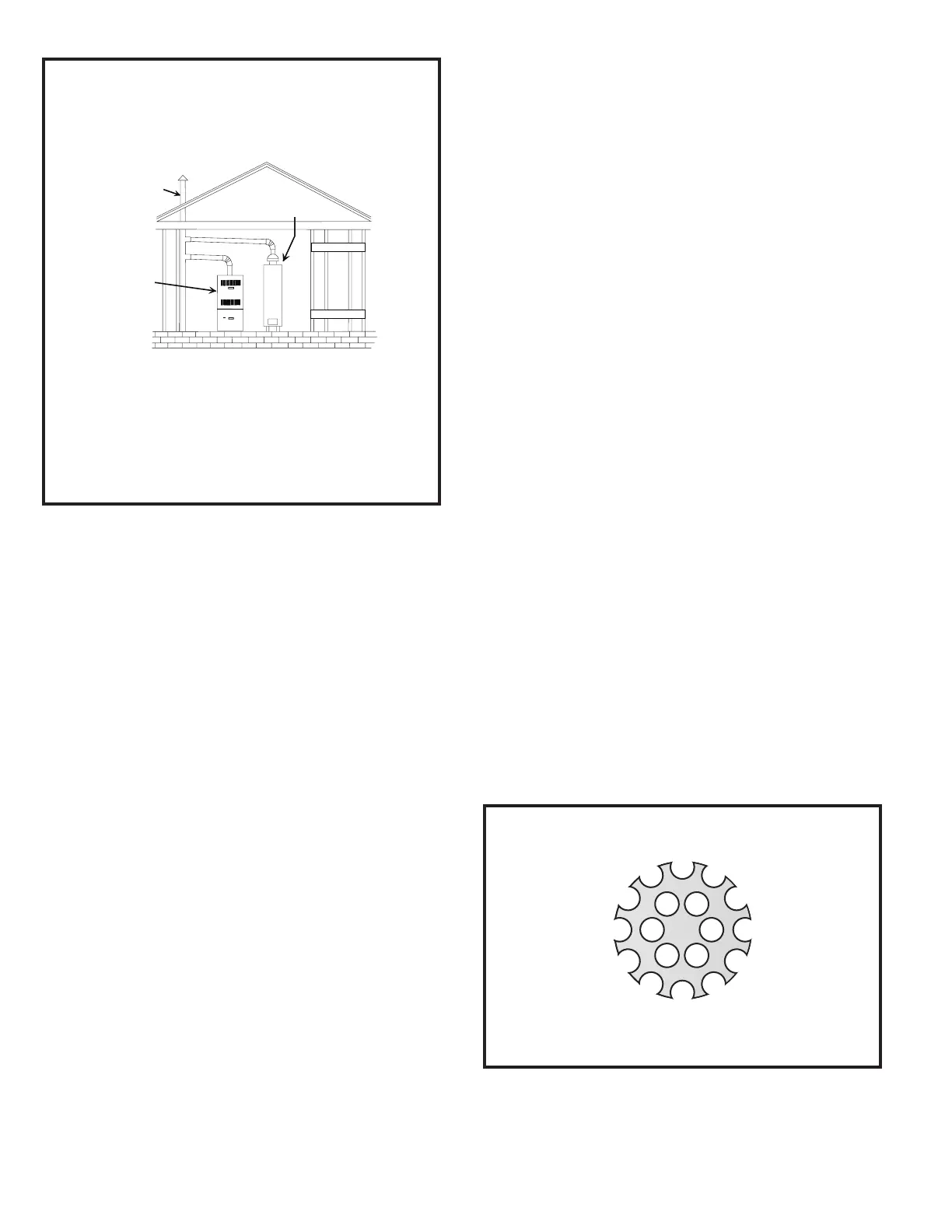

Figure 7

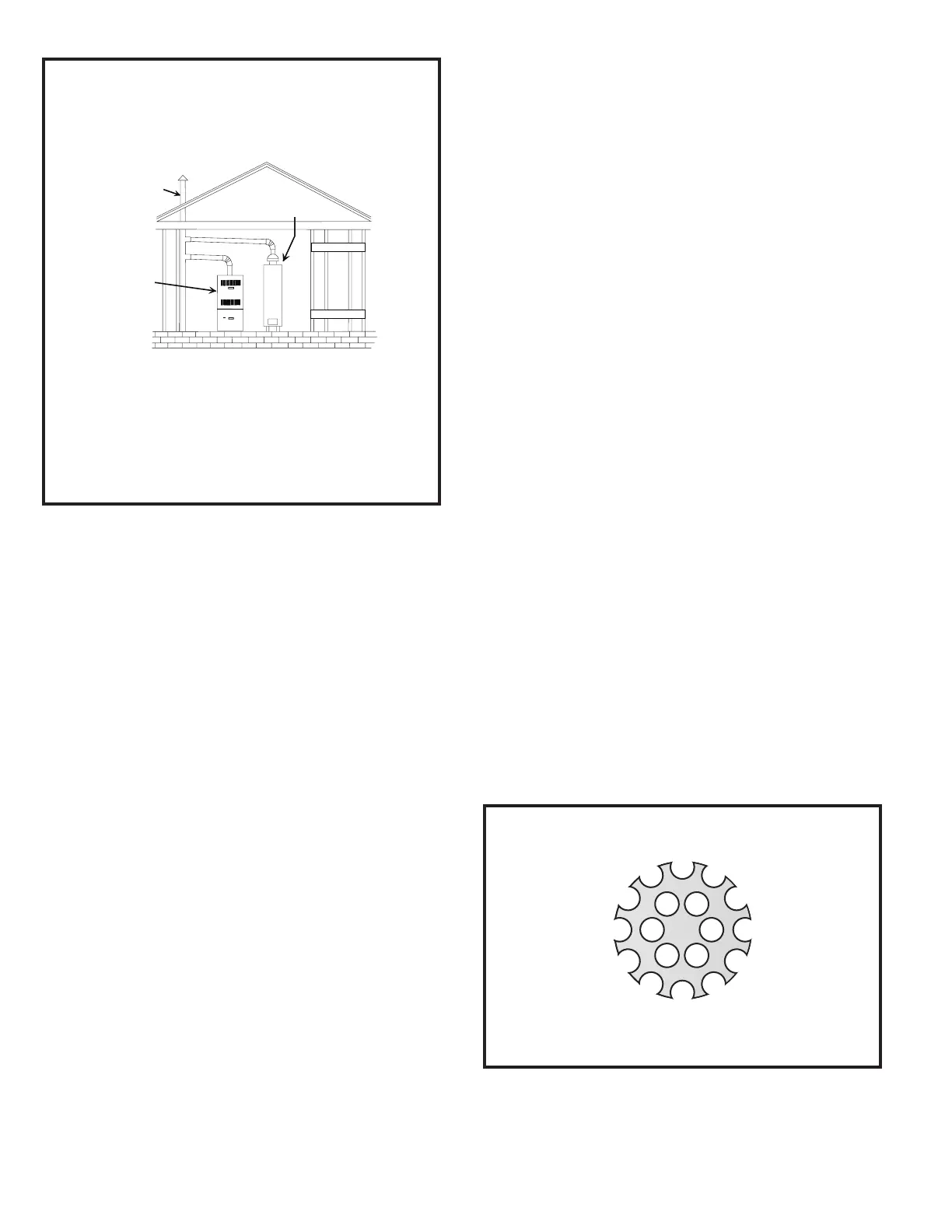

Inlet Air Restrictor Plate

The inlet air restrictor plate must be installed in all

installations using inside air for combustion (non-direct vent).

Contaminated Combustion Air

Excessive exposure to contaminated combustion air will

result in safety and performance related problems. The

recommended source of combustion air is outdoor air.

However, the use of indoor air in most applications is

acceptable if the following guidelines are followed:

1. If the furnace is installed in a confined space, it is

recommended that the necessary combustion air

come from the outdoors by way of an attic, crawl

space, air duct, or direct opening.

2. If indoor combustion air is used, there must be no

exposure to the substances listed in item 5.

3. All provisions for indoor combustion air must meet the

requirements for combustion air indicated in the

National Fuel Gas Code, ANSI Z223.1/NFPA 54

(latest edition), and/or any applicable local codes. In

Canada, see CSA B149.1, Natural Gas and Propane

Installation Codes (latest edition).

4. The following types of installation may require out-

door air for combustion, due to chemical exposures:

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry rooms

• Furnaces installed in hobby or craft rooms

• Furnaces installed near chemical storage areas

5. Exposure to the following substances in the combustion

air supply may also require outdoor air for combustion:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine-based swimming pool chemicals

• Water softening chemicals

• Deicing salts or chemicals

• Carbon tetrachloride

• Halogen-type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

• Chlorinated laundry products

• Hydrochloric acid

Venting

This furnace has a fan-assisted combustion system designed

for vertical venting into a suitable chimney or listed gas vent,

and is classified as a Category I furnace (negative vent) as

shipped from the factory. This furnace is dual certified as a

direct vent using outside air for combustion or it can use air

from inside the structure. See Figures 14 – 16 on pages 11

and 12 for optional outside combustion air applications.

The furnace is shipped with the air inlet pipe terminated to

the top panel for either inside or outside combustion air. An

inlet air restrictor plate (see Figure 7) is supplied with this

furnace and can be found in the plastic bag containing these

Installation Instructions and the User’s Information Manual.

For installations using inside air for combustion, the inlet air

restrictor plate must be installed as shown in Figure 8. Two

different sized inlet restrictor plates are supplied with the

furnace (2" and 3"). The 3" restrictor plate should be used

with non-direct vented 100K and larger models only; all

other non-direct vented models use the 2" restrictor plate.

Figure 6

Equipment in Confined Space

All Air from Outside

(All Air Through Horizontal Ducts)

Chimney or

Gas Vent

Furnace

Water Heater

Outlet Air

Inlet Air

Note: Each air duct opening shall have a free area of at least one

square inch per 2000 BTU per hour of the total input rating of

all equipment in the enclosure. If the equipment room is

located against an outside wall and the air openings

communicate directly with the outdoors, each opening shall

have a free area of at least one square inch per 4000 BTU

per hour of the total input rating of all other equipment in the

enclosure.

Loading...

Loading...