506303-01

Page 24 of 40 Issue 0938

Soft Stop

At the end of a cooling or heating cycle, the variable speed

motor will slowly ramp down after a short blower “off” delay.

If continuous blower operation has been selected, the

variable speed motor will slowly ramp down until it reaches

the airflow for that mode.

Passive and Active Dehumidification

Passive Dehumidification

For situations where humidity control is a problem, a

dehumidification feature has been built into the variable

speed motor. At the start of each cooling cycle, the variable

speed motor will run at 82% of the rated airflow for 7.5

minutes. After 7.5 minutes has elapsed, the motor will

increase to 100% of the rated airflow.

Active Dehumidification

To achieve additional dehumidification, clip the jumper wire

located below the DEHUM terminal on the integrated ignition/

blower control board and connect a humidity control that

opens on humidity rise to the DEHUM and R terminals. The

DEHUM terminal on the control board must be connected to

the normally closed contact of the humidity control so that the

board senses an open circuit on high humidity. In this setup,

the variable speed motor will operate at a 18% reduction in

the normal cooling airflow rate when there is a call for

dehumidification.

Both the passive and active dehumidification methods

described above can be utilized on the same furnace.

Circulating Airflow Adjustments

Cooling Mode

The units are factory set for the highest airflow for each model.

Adjustments can be made to the cooling airflow by

repositioning the jumper plug marked COOL – A, B, C, D

(see Figure 36) based on the information found in the table.

To determine what CFM the motor is delivering at any time,

count the number of times the amber LED on the control

board flashes. Each flash signifies 100 CFM; count the flashes

and multiply by 100 to determine the actual CFM delivered

(for example: 10 flashes x 100 = 1000 CFM).

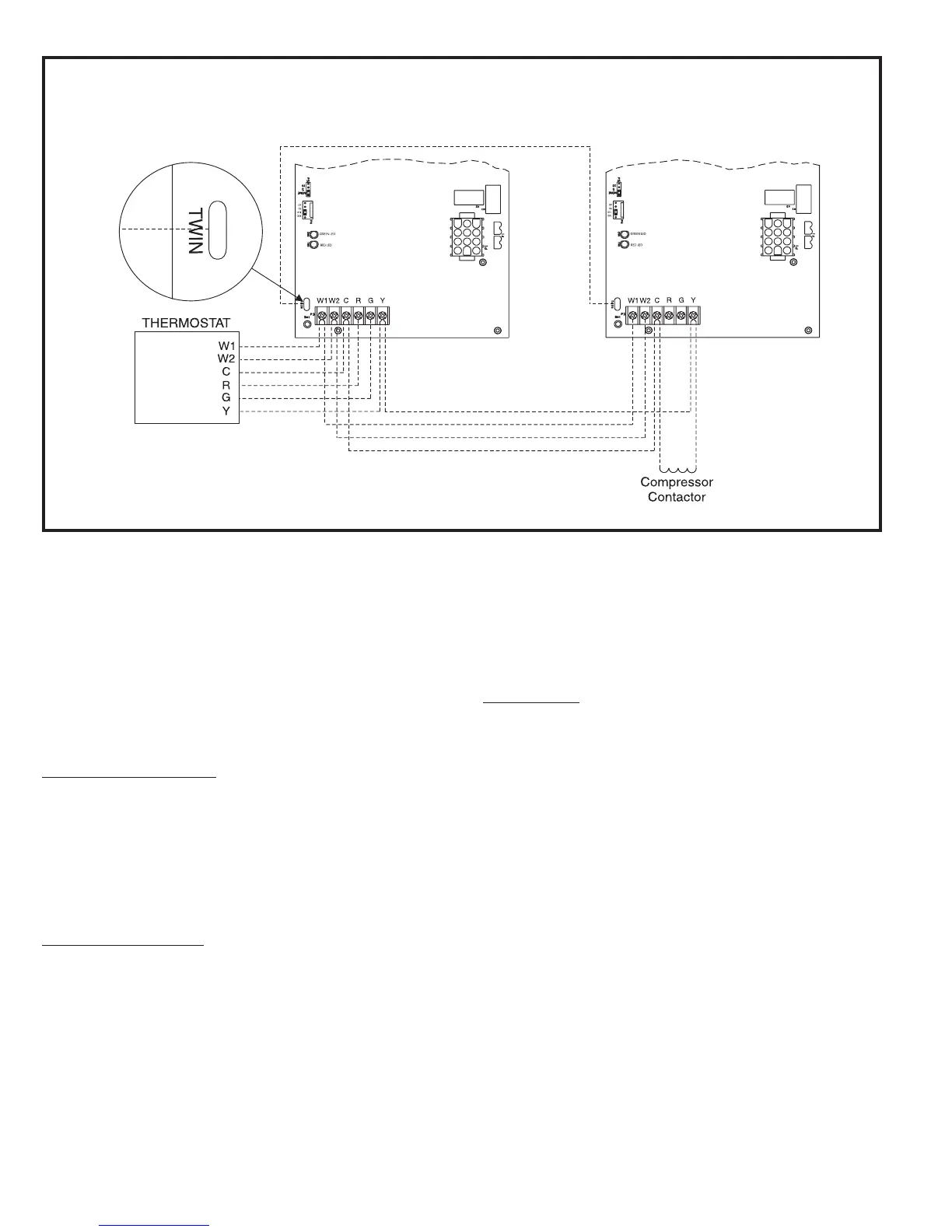

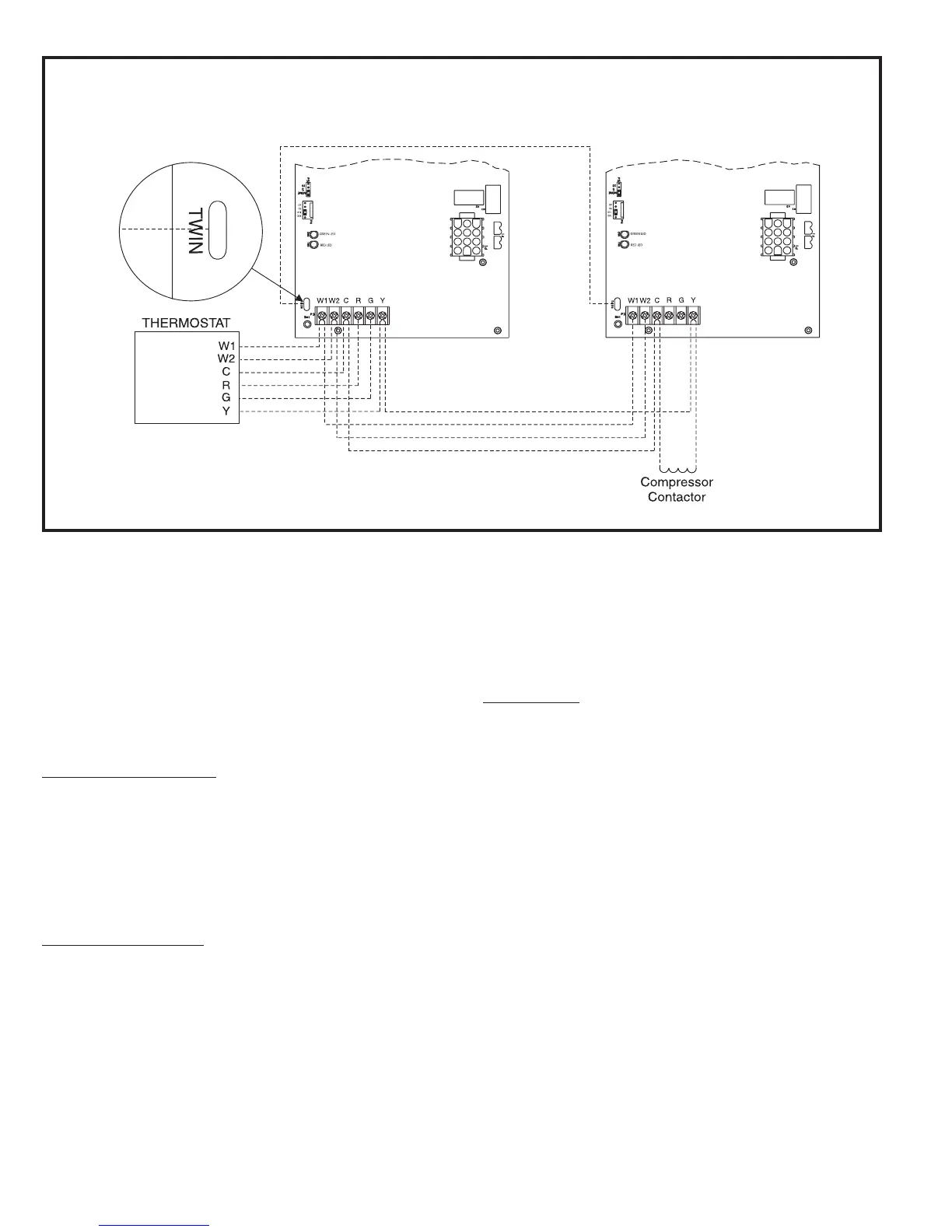

Figure 35

Wiring Connections for Twinning Two G2D93CT/U Furnaces

Two Stage Heating/Single Stage Cooling

Loading...

Loading...