506303-01

Page 30 of 40 Issue 0938

Auxiliary Limit Control

This is a normally closed control that opens under abnormal

“reverse air flow” conditions that could occur in a counterflow

or horizontal installation if the circulating blower fails. It is

an automatic reset control.

G2D93CU and G2D95CU models do not include an auxiliary

limit control.

Interlock (Blower Door) Switch

When the blower door is removed, the interlock switch

breaks the power supply to the burner controls and blower

motor. The switch operation must be checked to confirm it

is operating correctly.

System Sentry™ Integrated Ignition/Blower Control Board

The System Sentry™ integrated ignition/blower control board

operates all functions of the furnace and the accessories

connected to it.

G2D93CT/U models feature user-selectable blower “off”

delay times (60, 90, 120, and 180 seconds) that are factory

set to provide a 120-second blower “off” delay on heating

(see wiring diagram on page 35).

Refer to the furnace wiring diagram while using the following

procedure to the change motor speed on a G2D93CT/U

furnace:

1. Turn off electrical power to the unit.

2. Connect the desired speed tap for cooling on the

integrated ignition/blower control board.

3. For heating speed, check the temperature rise and, if

necessary, adjust the blower speed tap to maintain

temperature rise within the range shown on the furnace

rating plate.

To use the same speed tap for both heating and cooling,

install a piggyback terminal on the speed tap using a

short jumper. Wire 1/4" quick connect terminals on both

ends to jumper the “HEAT” and “COOL” speed on the

integrated ignition/blower control board.

4. The remaining speed taps must be connected to dummy

terminals marked “PARK” on the integrated ignition/

blower control board.

Checking and Adjusting Gas Input

The minimum permissible gas supply pressure for the

purpose of input adjustment is 5" W.C. for natural gas or

11" W.C. for propane gas. This furnace requires conversion

for use with propane (see Accessories section on page 35

for correct kit). The maximum inlet gas supply pressure is

10.5" W.C. for natural gas and 13" W.C. for propane. Gas

input must never exceed the value shown on the furnace

rating plate.

These units are rated for outlet (manifold) pressures of 1.7 "

W.C. (1

st

stage) and 3.5" W.C. (2

nd

stage) for natural gas. When

these furnaces have been converted for use with propane

gas, the outlet pressures are 4.9" W.C. (1

st

stage) and 10.0"

W.C. (2

nd

stage).

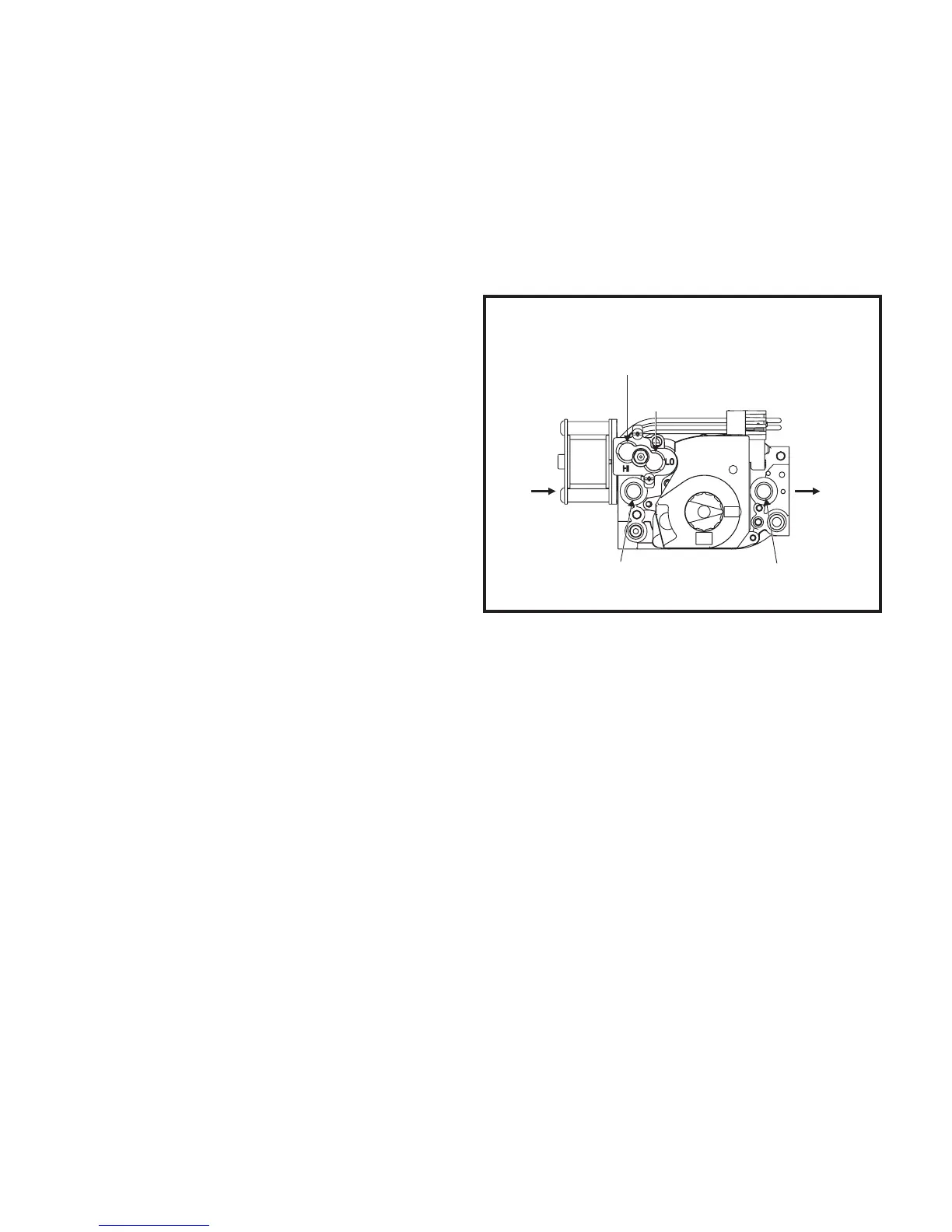

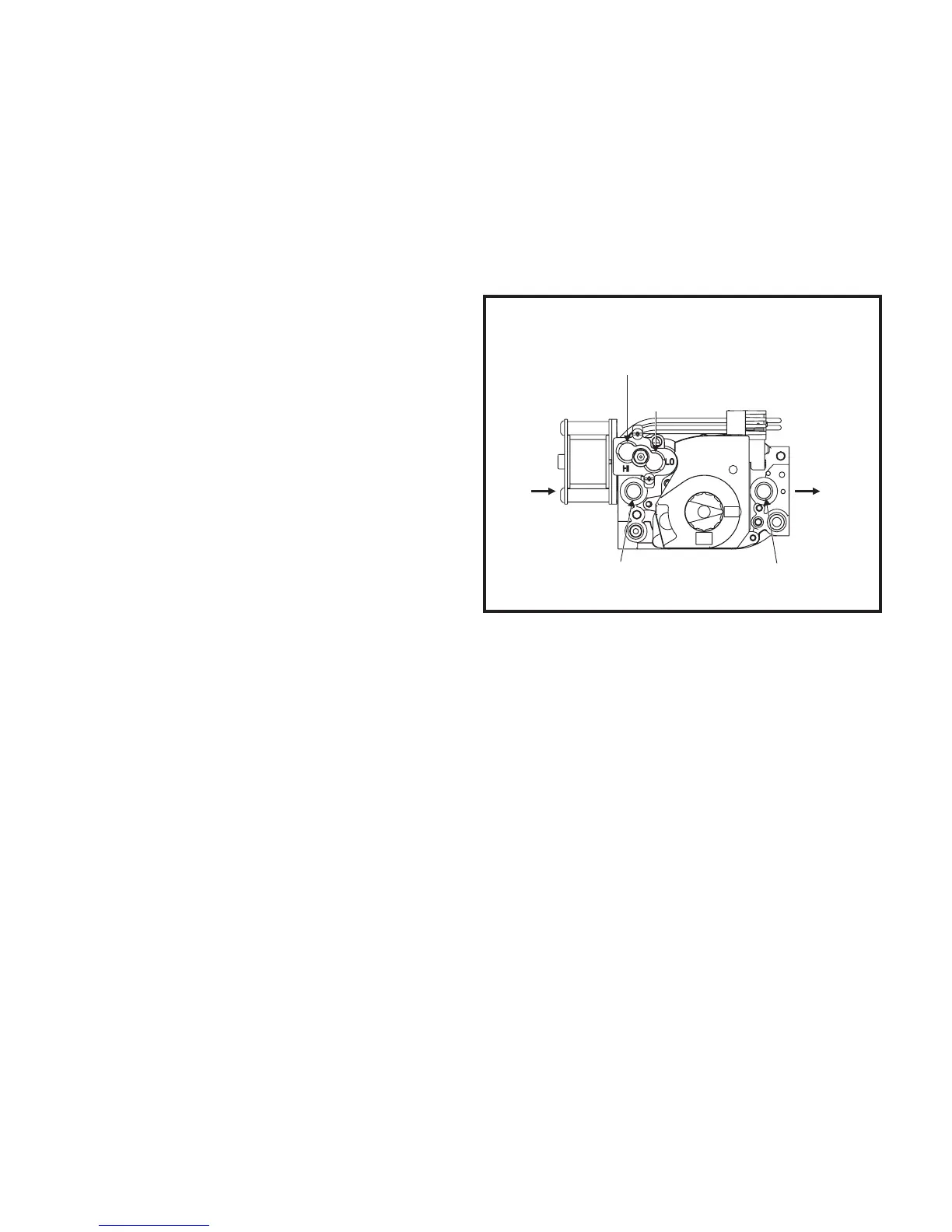

To measure inlet or outlet pressure, remove plug from

desired pressure tap (inlet or outlet) as shown in Figure 42

and connect a water manometer or gauge to the proper

pressure tap.

These models have separate adjusting screws (3/32" hex)

for 1

st

stage (marked “LO”) and 2

nd

stage (marked “HI”). The

adjusting screws are positioned on either side of the barbed

fitting (see Figure 42). Turn the adjusting screws clockwise to

increase pressure and input; counterclockwise to decrease

pressure and input. The pressure regulator adjustment is

sensitive; one turn of the adjusting screw will result in a

relatively large change in manifold pressure.

To adjust the regulator:

1. Set high-fire (2

nd

stage) setting by turning hex

adjustment screw to desired rate.

2. Set low-fire (1

st

stage) setting by turning hex adjustment

screw to desired rate.

Make sure the final high- and low-fire manifold

pressures are within the allowable ranges specified

above for the gas being used.

Checking and Adjusting Gas Input

Figure 42

OFF

ON

Inlet Pressure Tap

1/8" NPT

Outlet Pressure Tap

1/8" NPT

High-Fire (2 Stage) Adjustment

Under Vent Cap

nd

Low-Fire (1 Stage) Adjustment

Under Vent Cap

st

Loading...

Loading...