Do you have a question about the Armstrong VMS Series and is the answer not in the manual?

Manual contains vital information for reliable operation and avoiding risks.

Explains icons and symbols used for safety warnings and instructions in the manual.

How to find pump identification and operating data from the nameplate for specific models.

How to find pump identification and operating data from the nameplate for specific models.

Details material codes for shaft seals according to EN 12756.

Lists other available documentation for the pumps.

Explains nominal current for motor protection and electrical equipment.

Explains maximum current for motor protection and electrical equipment.

Details the warranty period, conditions, and invalidation factors for the product.

General safety information and disclaimer for product use, installation, and maintenance.

Defines requirements for personnel involved in operation, maintenance, and installation.

Information on product design, original parts, and risks of using non-original parts.

Safety precautions for normal operation of the pump.

Safety precautions for installation, maintenance, and repair procedures.

Explains the model designation and its components for pumps.

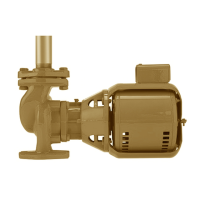

Describes the vertical, multi-stage centrifugal pump series and their features.

Explains the modular assembly of pumps based on application requirements.

Basic operational principles of the pump.

General information for installing pumps in hazardous environments with ATEX permission.

Explains pump and motor indication stickers for explosion safety.

Checklist for commissioning pumps in hazardous environments.

Guidelines for safely transporting the pump.

Recommendations for storing the pump, including frost protection.

Instructions for setting up the pumps, including connection stress and stability.

Steps to install a motor on pumps supplied without one, with a standard mechanical seal.

Commissioning procedure for pumps with sufficient supply pressure.

Commissioning procedure for pumps with liquid level lower than the pump.

Procedure for checking mechanical seals after extended storage or non-operation.

States that pump operation is controlled externally and needs no specific guidance.

General precautions for maintenance and contact for regular maintenance.

Lubrication guidelines for motors and pumps, including bearing lubricant type.

Steps to maintain the pump during extended periods of non-operation, including frost protection.

Procedure for replacing the non-return valve on VMSE pump types.

A table listing common pump problems, their possible causes, solutions, and checkpoints.

Lists available spare part kits with their corresponding kit numbers.

Provides technical specifications for pumps with different motor types and frequencies.

Lists torques for coupling bolts based on material and dimensions.

Declaration of conformity for the pumps with relevant EU directives and standards.

| Model | VMS Series |

|---|---|

| Category | Water Pump |

| Type | Vertical Multi-Stage |

| Application | Water supply, pressure boosting, irrigation |

| Motor Power | 0.37 kW to 15 kW |

| Materials | Stainless steel, cast iron |

| Impeller Material | Stainless steel |

| Sealing | Mechanical seal |