46

3.7 Faults and their diagnoses using MCM

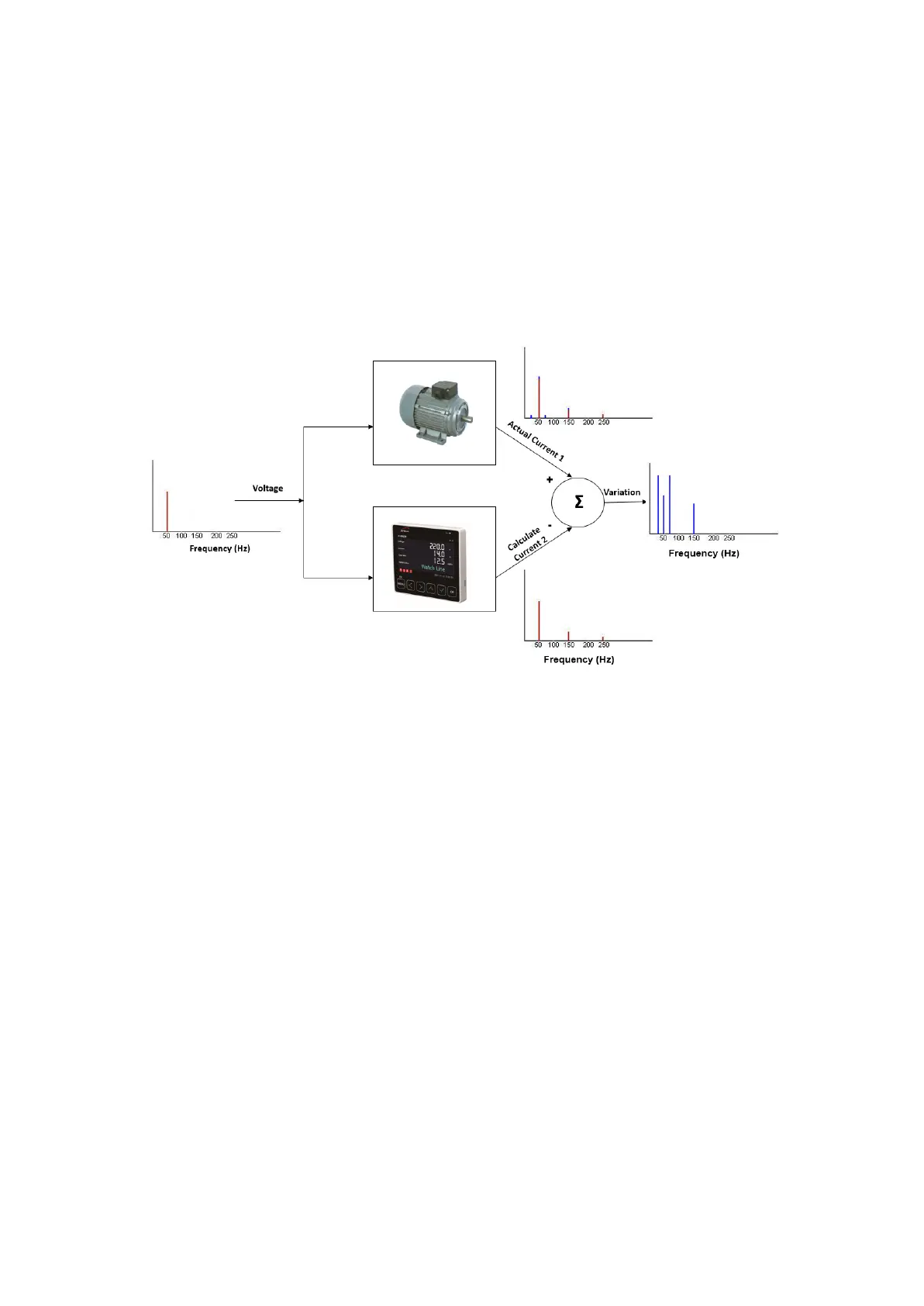

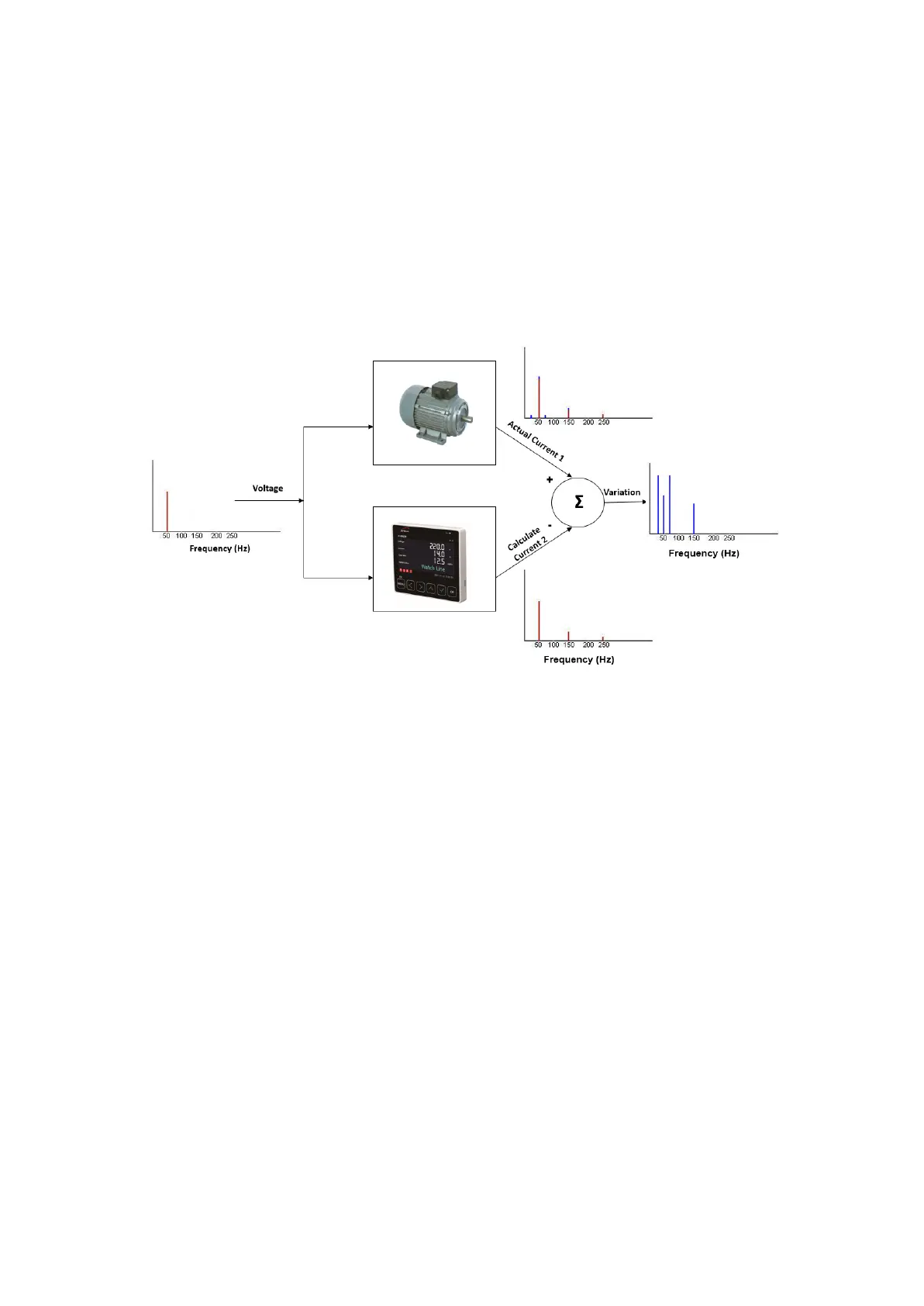

eMCM uses a model-based fault detection and diagnostics technique. In this technique, the

expected dynamic behavior (model) of the three-phase system under varying conditions, such as

load, is determined and compared with the measured dynamic behavior to monitor abnormalities.

eMCM first learns the system for a period of time through acquiring and processing the real-time

data from the system. The data is processed using system identification algorithms for the

calculation of expected dynamic behavior and the model parameters. The changes in the

parameters of the system indicate abnormalities developing in the system. Further, processing of

these parameters is used for diagnosis.

As opposed to traditional vibration and current signature analysis, this approach uses a cause-effect

(input-output) relationship and therefore is immune to the surrounding noise or noise in the inputs.

Also, the difference between expected and actual behavior filters out and enhances ONLY

abnormalities generated by the system, which allows for earlier and more accurate warnings. The

expert system approach eliminates the need for a database or record keeping, expert personnel,

time-consuming data gathering and analysis. It provides comprehensive (mechanical and electrical

as well as driven system) fault coverage though it measures only voltages and currents.

eMCM uses the electric motor of the equipment as a sensor. Therefore, any fault of the equipment

that affects the motor or the three-phase system is also observed by eMCM.

eMCM first learns the motor-based system for a period of time by acquiring and processing the

motor data. The results of the processed data are stored in its internal database and a reference

model is established. This reference model basically consists of model parameters, their mean

values and their standard deviations. While monitoring, eMCM processes the acquired motor data

and compares the results to the data stored in its internal database. If the results obtained from

the acquired data are significantly different from the reference model, eMCM indicates a fault level.

The level is determined by taking into account the magnitude and the time duration of the

difference. In total, eMCM monitors and compares 22 different parameters (model parameters).

These parameters are classified into three groups: electrical parameters, mechanical parameters

and fit parameters. These are explained in detail in the following sections.

3.7.1 Electrical Parameters

Loading...

Loading...