ASCON TECNOLOGIC - Y39E - OPERATING INSTRUCTIONS - Vr. Mondial Group - 10/10 - ISTR-MY39EENGmondial - PAG. 6

The differential is automatically considered by the regulator with

positive values for the Coolig Action or with negative values for the

heating action.

off

Out

Out

(ot)

(HE)

off

0N

SP

Pr1

Temp.

off

0N

r.d

r.d

time

0N

off

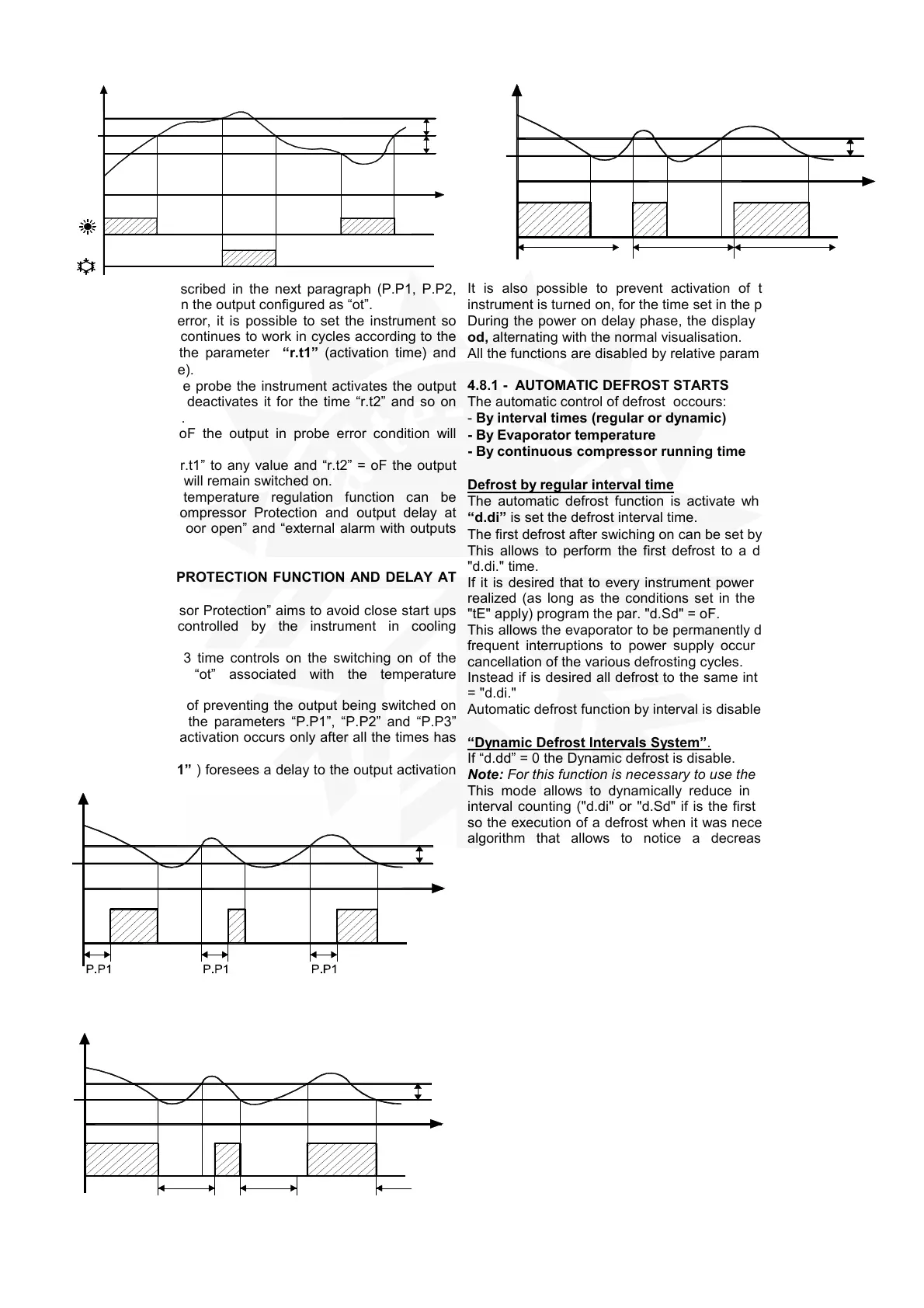

All time protections described in the next paragraph (P.P1, P.P2,

P.P3) always act only on the output configured as “ot”.

In the event of probe error, it is possible to set the instrument so

that that the output “ot”continues to work in cycles according to the

times programmed in the parameter “r.t1” (activation time) and

“r.t2” (deactivation time).

If an error occurs on the probe the instrument activates the output

for the time “r.t1”, then deactivates it for the time “r.t2” and so on

whilst the error remains.

Programming “r.t1” = oF the output in probe error condition will

remain switched off.

Programming instead “r.t1” to any value and “r.t2” = oF the output

in probe error condition will remain switched on.

Remember that the temperature regulation function can be

conditioned by the “Compressor Protection and output delay at

power-on”, “Defrost”, “Door open” and “external alarm with outputs

disable” functions.

4.7 - COMPRESSOR PROTECTION FUNCTION AND DELAY AT

POWER-ON

The function “Compressor Protection” aims to avoid close start ups

of the compressor controlled by the instrument in cooling

applications.

This function foresees 3 time controls on the switching on of the

output configured as “ot” associated with the temperature

regulation request.

The protection consists of preventing the output being switched on

during the times set in the parameters “P.P1”, “P.P2” and “P.P3”

and therefore that any activation occurs only after all the times has

finished.

First control (par. “P.P1” ) foresees a delay to the output activation

(switching-on delay).

Temp.

off

ON

SP

time

r.d

off off off

ON ON

Pr1

Out

(ot)

Second control (par. “P.P2” ) foresees an inhibition to the

activation of the output by a time delay that starts when the output

is turning off (delay after switching-off).

ON

off

P.P2

P.P2 P.P2

SP

Tem p.

tim e

r.d

ON ON

off off

Pr1

Out

(ot)

Third control (par. “P.P3” ) foresees an inhibition to the activation

of the output "Out" by a time delay that starts when the output was

turning on last time (delay between switching-on).

P.P3

off

SP

ON

Temp.

P.P3 P.P3

time

r.d

off off

ON ON

Pr1

(ot)

Out

During the output inhibition the led OUT (Cool o Heat) blinking.

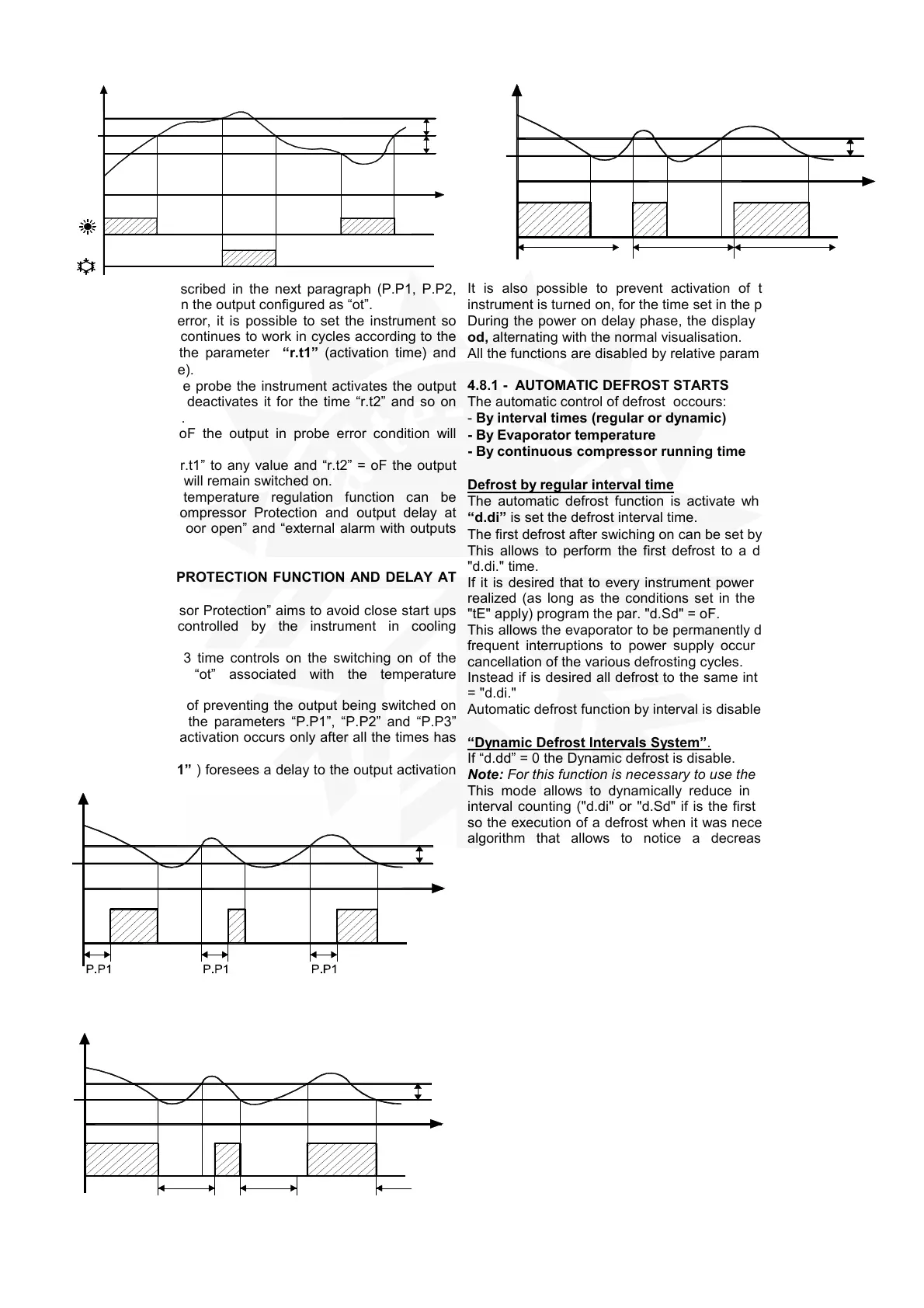

It is also possible to prevent activation of the output after the

instrument is turned on, for the time set in the parameter “P.od”.

During the power on delay phase, the display shows the indication

od, alternating with the normal visualisation.

All the functions are disabled by relative parameters = oF.

4.8.1 - AUTOMATIC DEFROST STARTS

The automatic control of defrost occours:

- By interval times (regular or dynamic)

- By Evaporator temperature

- By continuous compressor running time

Defrost by regular interval time

The automatic defrost function is activate when at the parameter

“d.di” is set the defrost interval time.

The first defrost after swiching on can be set by par. “d.Sd”

This allows to perform the first defrost to a different interval from

"d.di." time.

If it is desired that to every instrument power on a defrost cycle is

realized (as long as the conditions set in the parameters “tS” and

"tE" apply) program the par. "d.Sd" = oF.

This allows the evaporator to be permanently defrosted, even when

frequent interruptions to power supply occur that may cause the

cancellation of the various defrosting cycles.

Instead if is desired all defrost to the same interval program "d.Sd"

= "d.di."

Automatic defrost function by interval is disable when “d.di” = oF.

“Dynamic Defrost Intervals System”.

If “d.dd” = 0 the Dynamic defrost is disable.

Note: For this function is necessary to use the evaporator probe.

This mode allows to dynamically reduce in progress the defrost

interval counting ("d.di" or "d.Sd" if is the first defrost), anticipating

so the execution of a defrost when it was necessary, in order to an

algorithm that allows to notice a decrease performances of

refrigerator thermal exchange.

Besides it maintains activates the mode "St" that it allows a further

possibility of control of the defrost in order to notice a decrease

performances of refrigerator thermal exchange.

The algorithm allows to esteem a reduction of thermal exchange in

base to the increase of the difference of temperature between Pr1

(controlled temperature) and evaporator (“EP” probe) that is

memorized by the instrument in proximity of the Set Point.

The advantage of the “Dynamic Defrost Interval” is the possibility to

program a defrost interval time more longer than normal.

The instrument will have the possibility to anticipate the defrost if

necessary or to start the cycle after the programmed time.

If the system results set correctly is possible to to avoid many non

necessary defrosting cycles (and therefore to obtain an energy

saving) that could instead happens in the normal operation when,

to guarantee with greater certainty the system efficency , the

defrost interval is programmed at a too low time.

Loading...

Loading...