8

3 - Electrical Connections

3 ELECTRICAL

CONNECTIONS

PRECAUTIONS

B

Despite the fact that the instrument

has been designed to work in an

harsh and noisy environmental (level

IV of the industrial standard IEC 801-

4), it is strongly recommended to fol-

low the following suggestions.

A

All the wiring must comply with the

local regulations.

The supply wiring should be routed

away from the power cables.

Avoid to use electromagnetic con-

tactors, power relays and high power

motors nearby.

Avoid power units nearby, especially

if controlled in phase angle

Keep the low level sensor input wires

away from the power lines and the

output cables.

If this is not achievable, use shielded

cables on the sensor input, with the

shield connected to earth.

UL note

[1] Use 60/70 °C copper (Cu) conduc-

tor only.

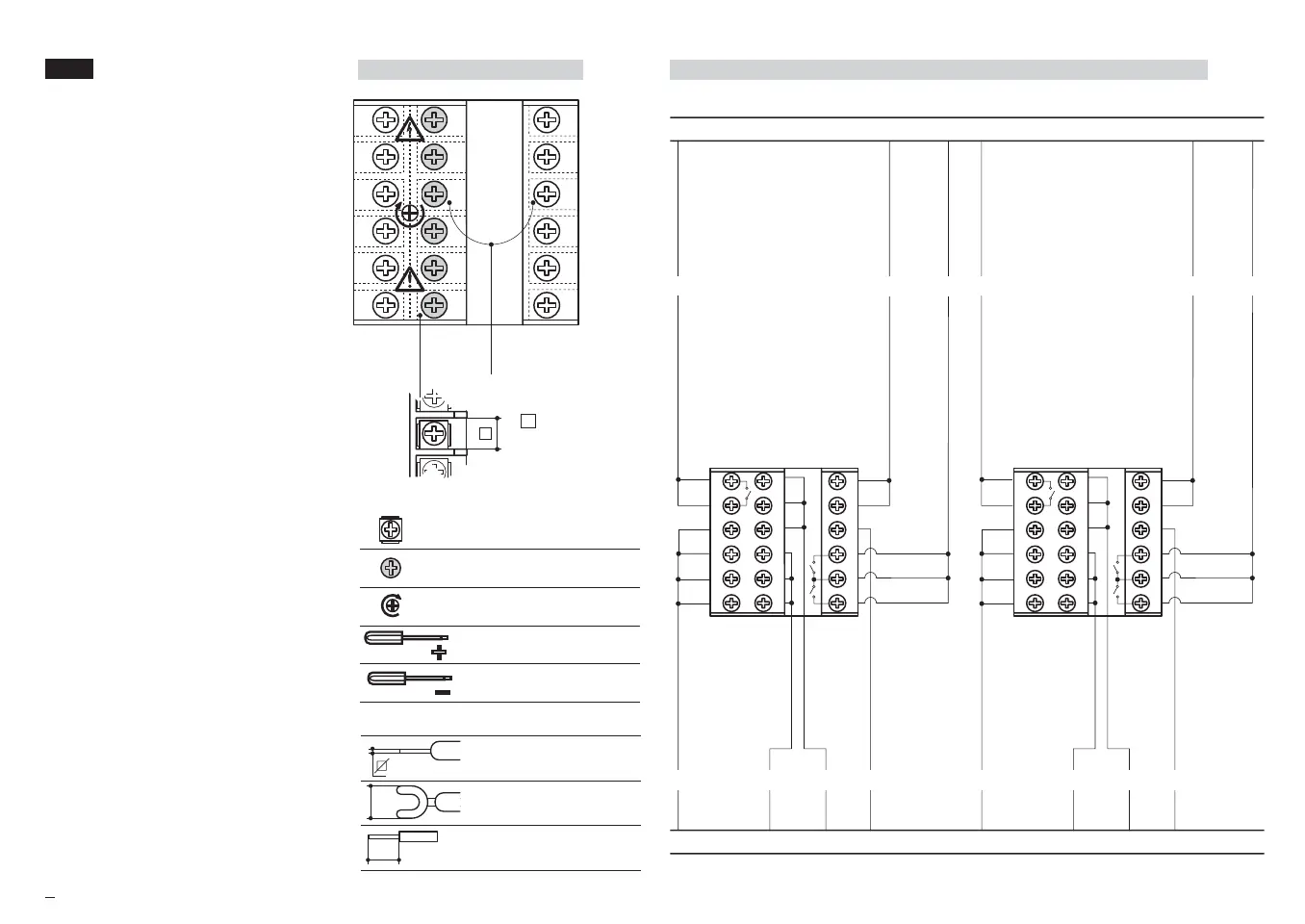

3.1 TERMINATION UNIT [1]

B

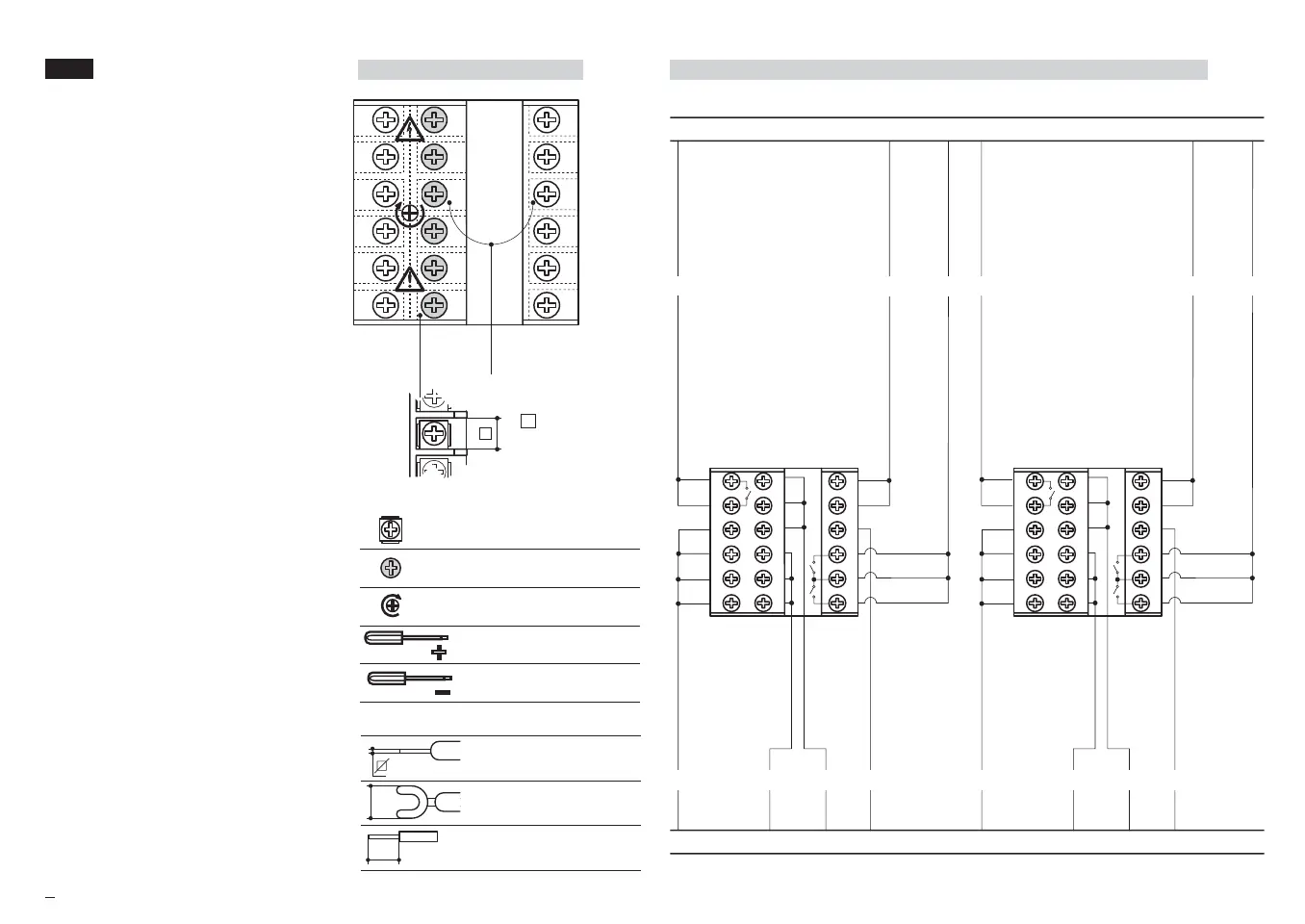

3.2 RECOMMENDED ROUTING OF WIRES

B

0,5

Nm

6

5

4

3

2

1

12

11

10

9

8

7

18

17

16

15

14

13

Rear

terminal

covers

Wire size

1 mm

2

(18 AWG

Solid/Stranded)

5.7 mm

0.22 in

6

5

4

3

2

1

12

11

10

9

8

7

18

17

16

15

14

13

6

5

4

3

2

1

12

11

10

9

8

7

18

17

16

15

14

13

Conduit for supply and output cables

Conduit for low level sensor cables

A

L

N

BB

CDE

A

L

N

BB

CDE

A = Supply

B = Relay/Triac Output

C = Analog Inputs

D = Serial

Communication

E = Auxiliary

Inputs/Outputs

F = Digital Inputs

FF

18 screw terminals

Option terminals

Holding screw 0.5 Nm

Positive screw

driver PH1

Negative screw

driver 0,8 x 4 mm

Terminals

Pin connector q 1.4 mm

0.055 in max

Fork-shape AMP 165004

Ø 5.5 mm - 0.21 in

Stripped wire

L 5.5 mm - 0.21 in

M5 UK•ed4 10-12-2004 16:20 Pagina 8

Loading...

Loading...