Exit Devices

Copyright ©2015 Yale Security Inc., an ASSA ABLOY Group Company. All rights reserved. Reproduction

in whole or in part without the express written permission of Yale Security Inc. is prohibited.

An ASSA ABLOY Group Brand

6100 / 6200

Series

For technical support contact Yale

®

at

800.438.1951 x5033 or support@yalelocks.com

80-9460-6016-000 10/15

ELECTRIC LATCH RETRACTION

Installation Instructions for

P Function and/or Monitors

Table 1:

Wires from Power Supply to Device

(Minimum Gauge of Two-Conductor Cable)

Up to 40 Feet of Wire 16 Gauge

Up to 60 Feet of Wire 14 Gauge

Up to 100 Feet of Wire 12 Gauge

1. Install the System Peripheral Components (782 Controller, Controlling

Switches, Power Transfer Hinge(s), etc.) and Raceways (Table 1).

IMPORTANT:

Do not connect power until all components are installed.

Integral Power Supply: Connect the wires from the Power Transfer

Hinge, Controlling Switch(es) Console and Power (120 VAC) input to the

782 Controller, as described in the controller installation instructions.

Power Transfer Hinge: Follow the manufacturers’ installation in-

structions. The door leaf wires must exit through the door access

hole, underneath the device rear clamp.

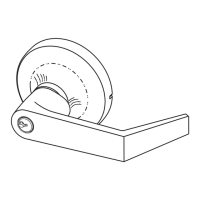

2. Install Device (and optional Trim): Follow the installation instruc-

tions for device (and trim). The Rear Clamp and End Cap are NOT

to be installed at this time.

3. Prepare Wiring Access Hole: Drill a 3/4˝ (19mm) diameter hole in

the door using the rear clamp center hole as a guide (Figure 1).

4. Install the rear clamp screws and fully tighten all device screws.

5. Check Device Action: Actuate the device by the touchbar (and

trim). Be sure that the door and device are operating properly and

that the door is opening freely and closing securely.

6. Connect Device ELR Wires: The red (+) and black (–) polarized

wires from the inactive (hinge) end of the device connect to

DEV 1 on the 782 (see the wiring diagram).

7. Connect Monitors (if used): Follow the connections shown in

Figure 2. Wire nuts are not supplied.

8. Coordinated Door Operation: When two (2) devices are

hooked to the same 782, repeat steps 2. through 7. and con-

nect the second device to DEV 2.

9. Test System: With the power disconnected, verify there are no

short circuits throughout.

Apply power to console (if used) and to integral power supply.

Test the device; bolt should retract when the controlling switch

closes contacts and extend when the switch contacts open.

During momentary or continued operation the device status will

correspond to the switch contact status.

Note:

The 782 Controller has an adjustable delay which causes the elec-

tric latch to remain retracted while the controlling switch is open.

The Troubleshooting Guide (Table 2) provides modifi cations.

Figure 1: Door Preparation

Exit Device Rear clamp

Mounting Holes

(for reference only)

Conducting Hinge

or Approved Power

Transfer (by others)

Inside Face of Door

Clear Channel Access

Required for Wire Connection

3/4˝ (19mm) Dia.

Wiring Access)

Horizontal Reference

Device Centerline

Hinge Edge

of Door

C

L

C

L

Exit Device

4˝ Max.