17

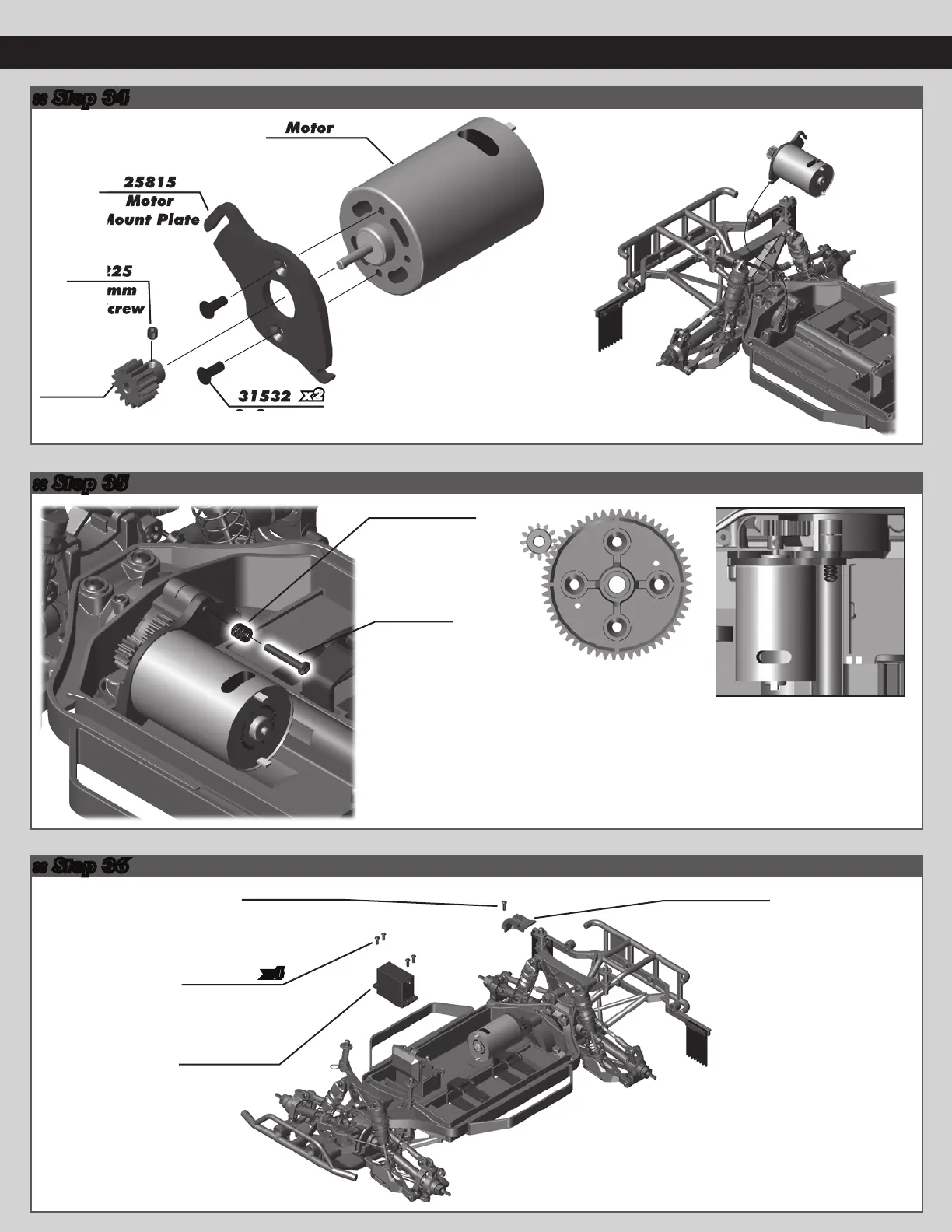

:: Step 34

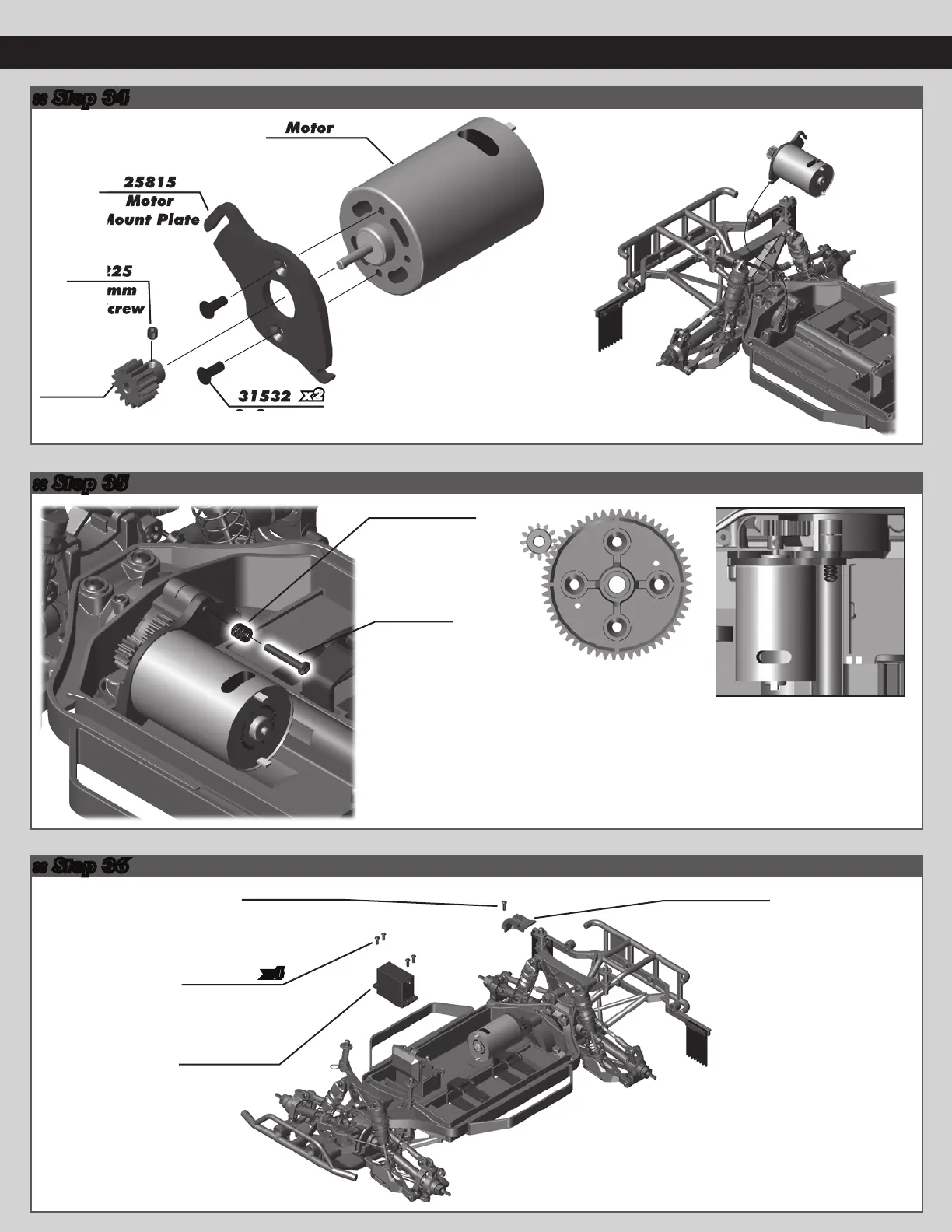

:: Step 35

:: Step 36

Set The Gear Mesh:

To set the gear mesh, rock the spur gear back and

forth without making the pinion gear move. Exessive

amounts of spur gear movement (loose gear mesh)

will cause premature gear failure. If the spur gear

mesh is tight, there will be no movement between the

spur and pinion gears. A gear mesh that is too tight

or too loose will reduce power and damage the gear

teeth.

x2

31532

3x8mm

FHCS

25815

Motor

Mount Plate

25225

3x3mm

Set Screw

25861

15T-32P

Pinion

Motor

25815

Motor Mount

Tension

Spring

25188

3x20mm

BHCS

25800

Spur Gear

Cover

x4

31532

3x8mm

BHCS

25211

3x10mm

BHCS

Servo

Loading...

Loading...