Page 5

16. Roll Feeder up to Duplicator. Adjust height of Conveyor to match Duplicator Front

Apron. If Feeder Front Stop Plate Hook is not even with upper edge of Duplicator’s Front

Apron, adjust Feed Stand. To adjust Stand height [Figure 4]: Loosen two knobs on

either side of Stand. Turning locking knobs counterclockwise unlocks Stand, which allows

it to be adjusted. Adjust height by turning third knob (Adjusting Knob) clockwise to raise

height of Stand, and counterclockwise to lower it. Tighten locking knobs after height is

adjusted. If Feeder is to be used on more than one Duplicator, adjust Duplicators to one

height (eliminating additional set up time).

17. Position slots on Feeder Front Stop Plate against Duplicator’s Paper Height Regulators.

Lift Feeder Conveyor and hook it over Duplicator’s Front Apron.

NOTE: Allow proper clearance between Height Regulators and Feeder Stop Plate.

18. Move Duplicator Paper Guides in until they touch Feeder Conveyor. Tighten Feeder

Conveyor clamp screw (located under Conveyor).

19. Connect Pulse Generator cable to Feeder cable.

Plug Feeder into 115VAC, 15 AMP outlet.

WARNING: POWER FLUCTUATIONS CAUSED BY AN OVERLOAD

OF EQUIPMENT ON SAME BRANCH CIRCUIT MAY AFFECT

FEEDER PERFORMANCE.

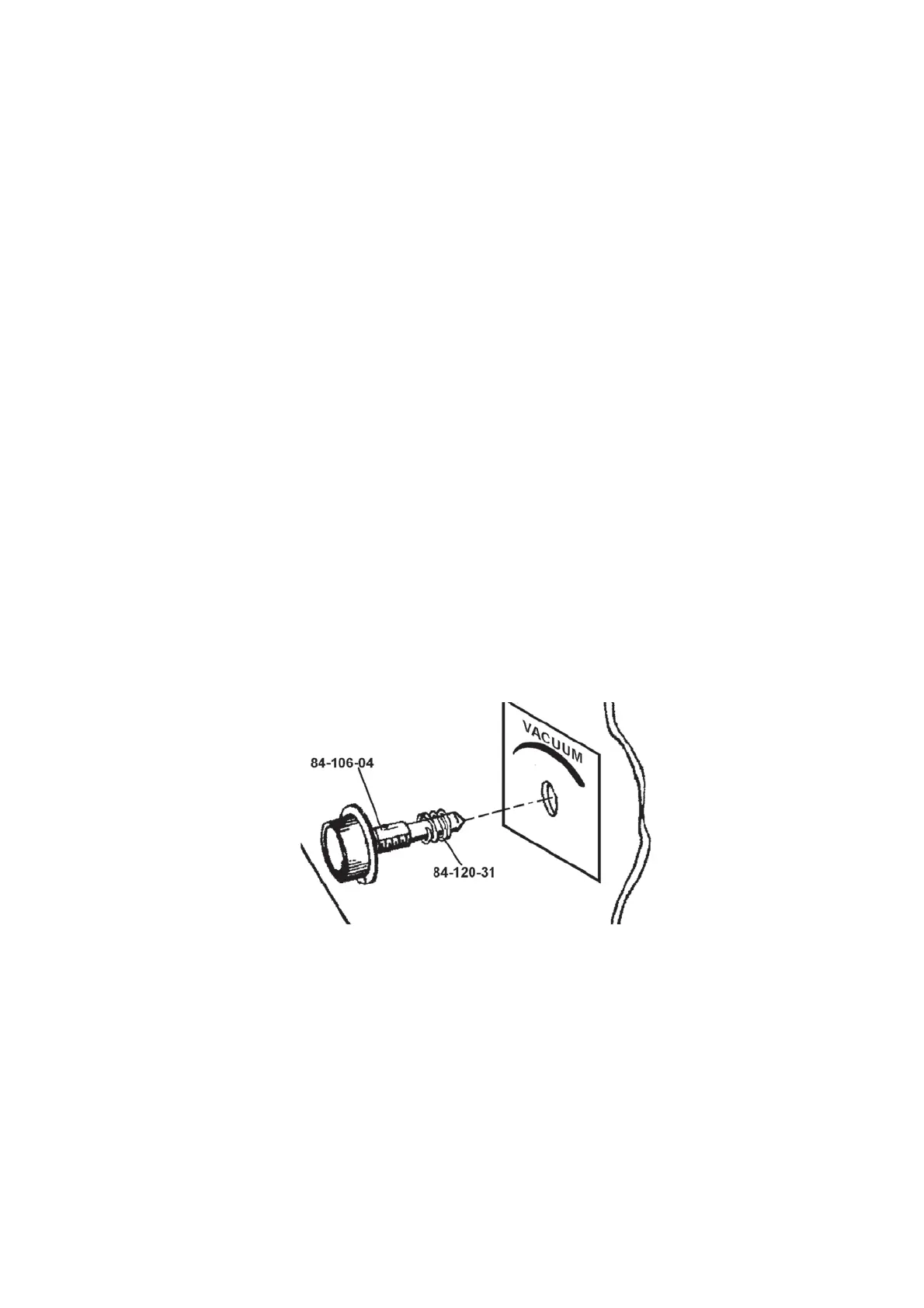

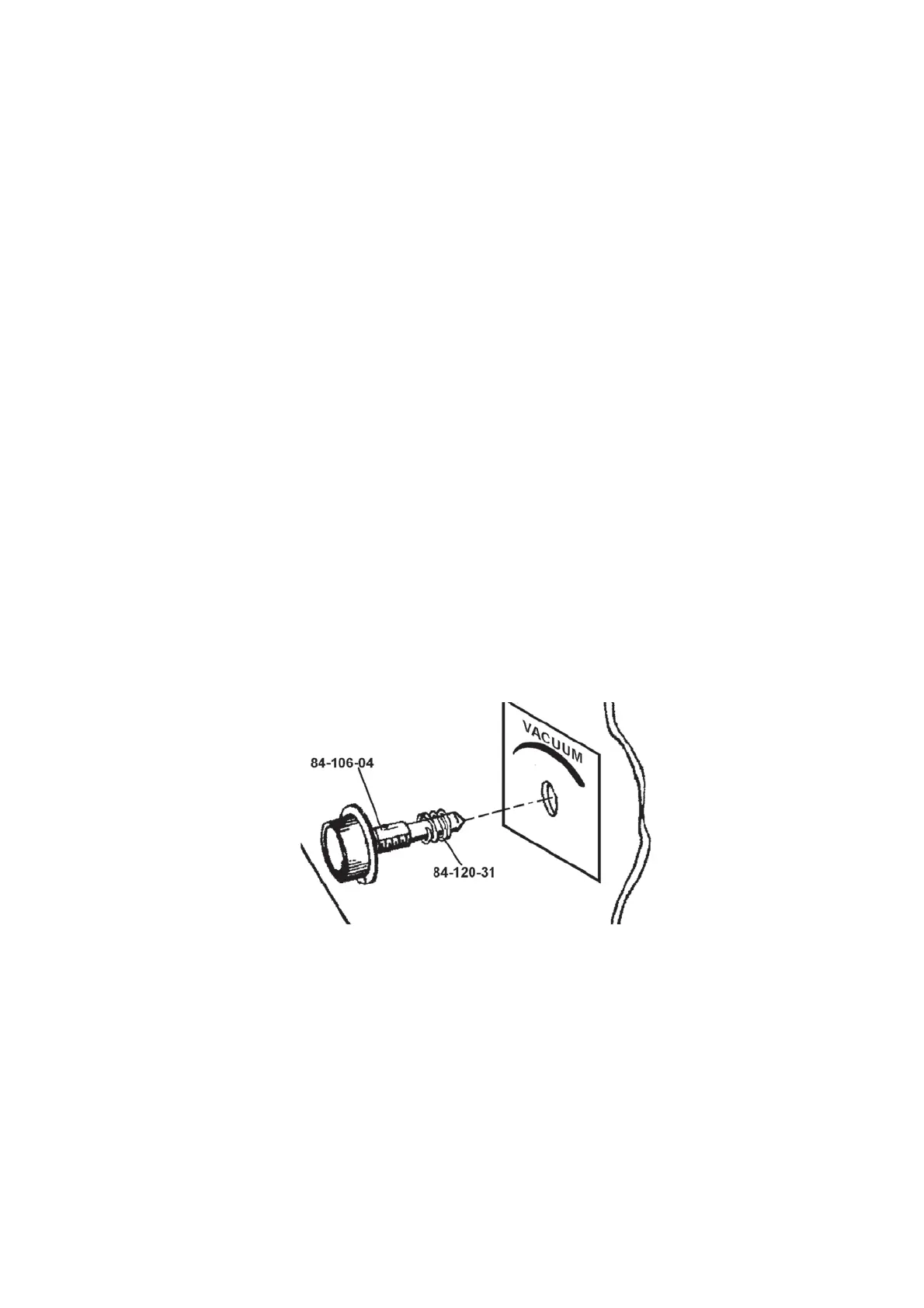

20. Install (84-120-31) Spring on (84-106-04) Needle Valve. Screw Needle Valve Assembly

into side of Envelope Feeder. (Figure 5)

WARNING: DO NOT OVERTIGHTEN VALVE AS DAMAGE TO

VALVE BODY CAN OCCCUR.

Loading...

Loading...