24

Radiator/oil cooler cleaning

The radiator and oil cooler must be

clean to ensure proper operation. Engine

and hydraulic system overheating, dam-

age and even failure can result if the

radiator/oil cooler is not kept clean. A

pressure washer or compressed air noz-

zle work well to blow debris clear of the

fins in the oil cooler and radiator.

Note: If hydraulic oil or engine coolant

temperature lights illuminate during

operation, increase cleaning intervals.

Note: In brush cutting applications

check and clean the coolers and chassis

often to avoid overheating and prevent

fires.

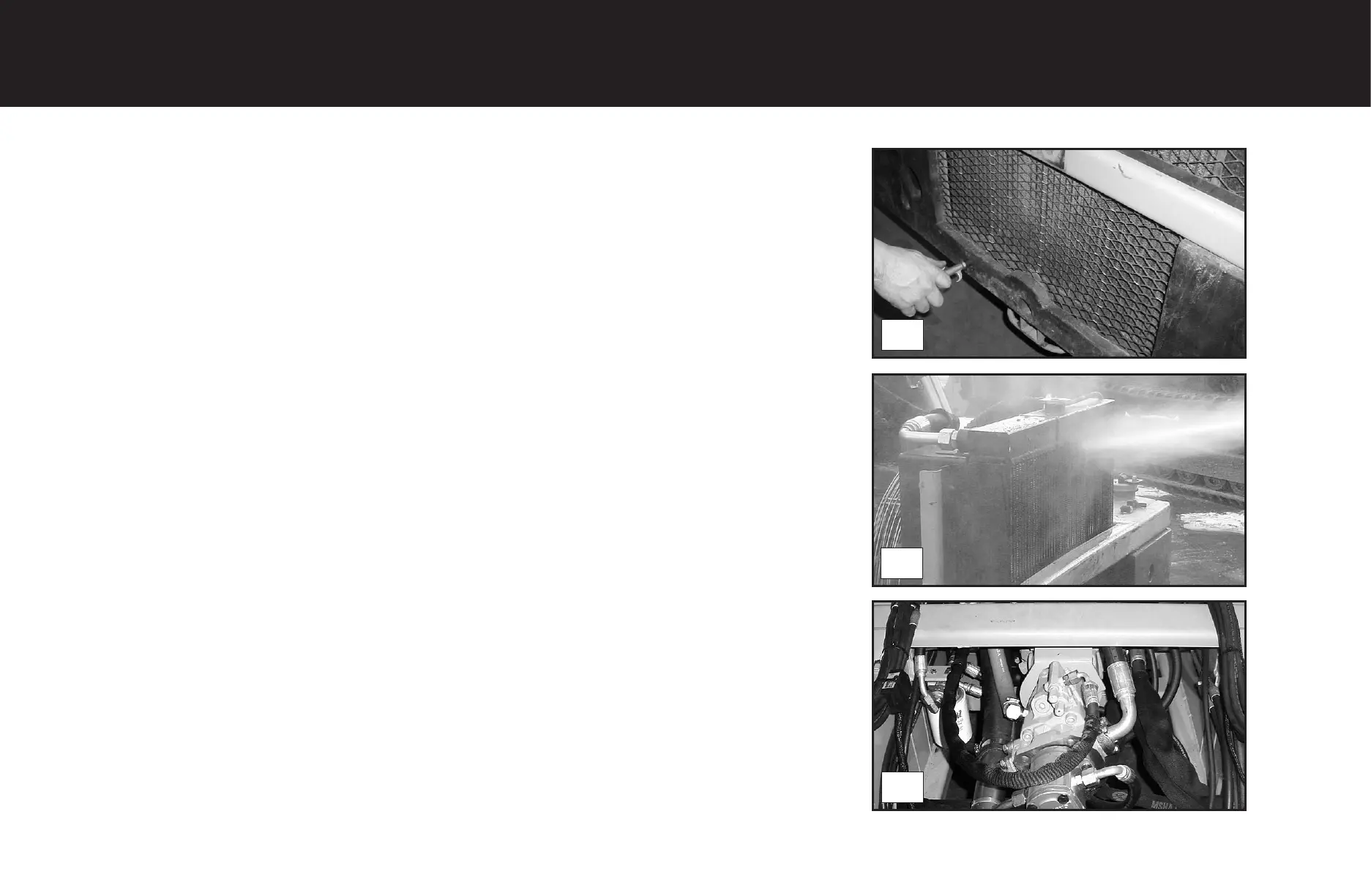

To clean radiator and oil cooler:

1. Make sure the engine is off, and

cool during radiator/oil cooler

cleaning procedure.

2. Thoroughly clean radiator/oil cooler

prior to operation. Direct spray

forward as shown. (fig. 1,2)

Note: Make sure water nozzle is at least

12” (8” for air) from the cooler and

that the spray is directed straight

through the cooler or the cooling fins

may be damaged (bent over) which will

decrease cooling performance.

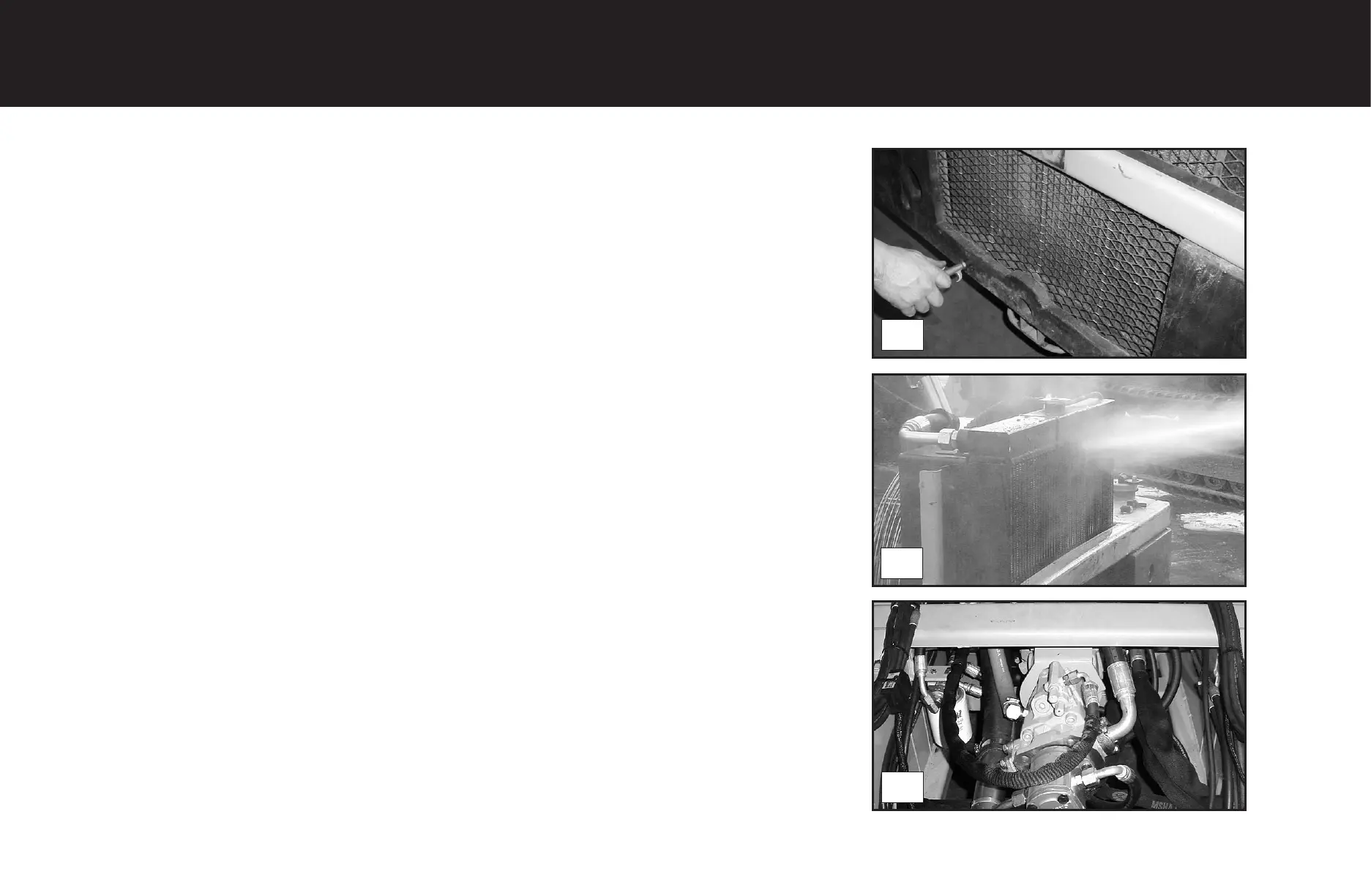

Chassis and engine cleaning

Periodic cleaning of the chassis area

beneath the cab and engine compartment

are also necessary to maintain safe oper-

ation. Clean as necessary. (fig. 3)

1. Remove the belly pans on the

underside of the machine.

2. Raise the hood at the rear of the

machine.

3. Pressure wash any debris from the

engine compartment and chassis

area out through the lower opening.

4. Re-install the belly pans and close

the hood to complete the cleaning

procedure.

Machine Maintenance

1

2

3

Loading...

Loading...