Instruction book

94 6996 0227 40

Oil separator elements clogged

Check couplings and outlet

Bypass valve or oil injection

system clogged

Have bypass valve cleaned or replaced.

Clean oil injection system

Pressure switch out of order

Vacuum pump element

outlet temperature above

normal

Check and correct, see

Operation instructions / During

operation

Insufficient cooling air or cooling

air temperature or relative

humidity is too high

Check for cooling air restriction or

improve ventilation of the

vacuum pump room. Avoid recirculating of

cooling air. If installed, check capacity of

vacuum pump room fan

By-pass valve malfunctioning

Check service intervals, see

Preventive maintenance

schedule

Temperature of pressure air too

high

Check process air temperature

Vacuum pump element out of

order

Converter fault codes

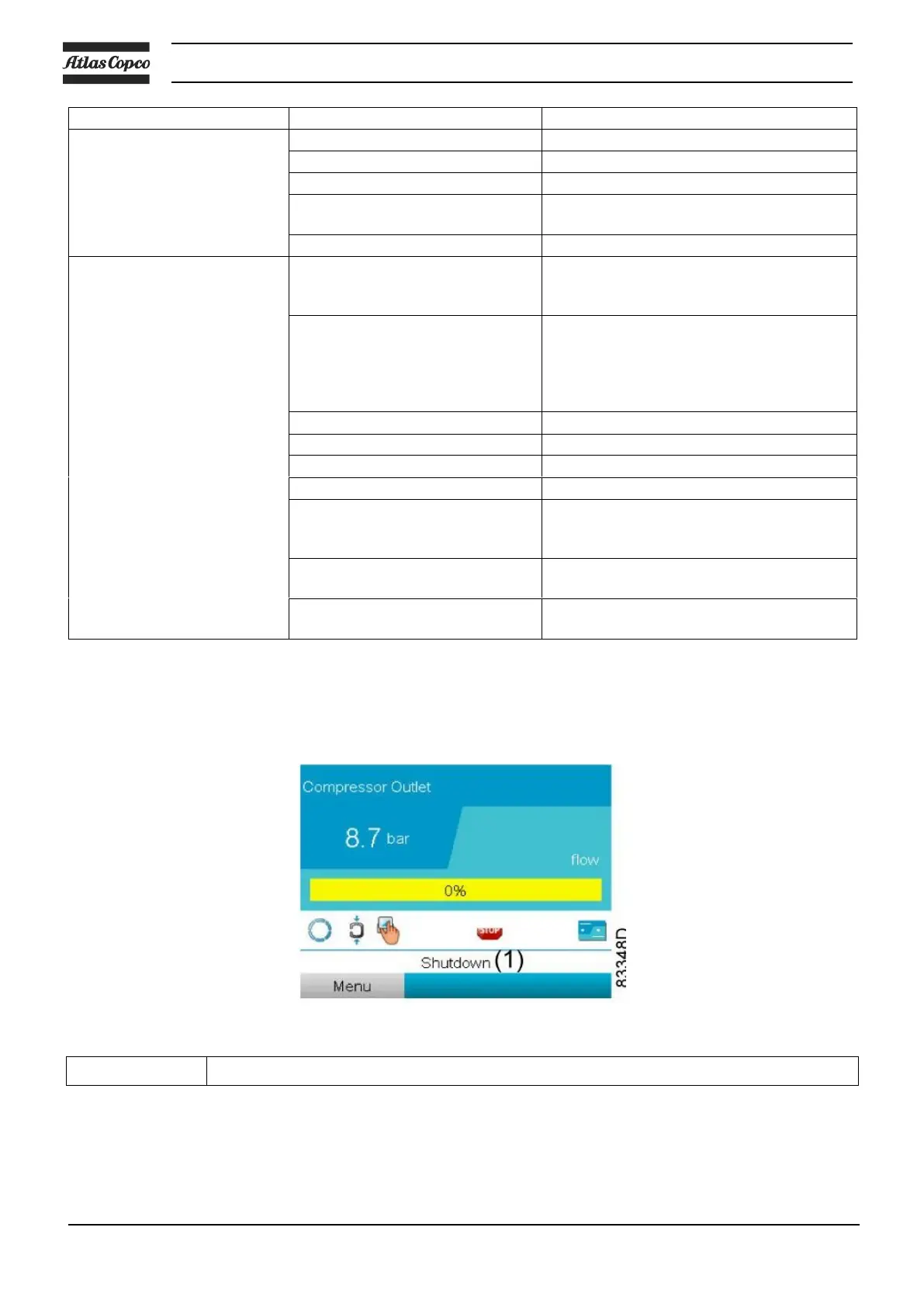

If a problem is detected by the converter, a specific code (Main motor converter alarm) will appear on the

Elektronikon display, together with a fault code. Below table lists the most important error codes. If another code

appears, please contact Atlas Copco.

Typical display when the vacuum pump is stopped by a shutdown

Navigate to the Stop icon or to the Protections icon and press Enter.

Loading...

Loading...