2920 1449 00

25

Instruction book

Important

The regulator will only react to a new control mode if the new

position of the control mode switch is maintained for 3 seconds.

To avoid unauthorized switching over to another control mode,

take out the key after selecting the required mode.

3.1.6 Initial start-up

1. Consult section 2 for the electric cable size, installation

proposal and dimension drawings.

2. Read the "User manual for Elektronikon

®

regulator for GA-

GR-ZE-ZA-ZR-ZT" to familiarize yourself with all

regulator functions.

3. A sticker dealing in short with the operation instructions is

delivered with the literature set. Affix the sticker next to

the control panel.

4. Stick labels near the control panel warning the operator that:

- the compressor may automatically restart after voltage

failure

- the compressor is automatically started and stopped

- the compressor may be remotely controlled.

5. A number of VCI (Volatile Corrosion Inhibitor) plates are

provided inside the bodywork to protect the compressor

against corrosion. Remove the plates.

6. The gear casing supports, motor support and air receiver

supports are secured to the frame, immobilizing the vibration

dampers during transport.

Remove bushes (1-Fig. 3.1) from both gear casing supports

as well as bushes (1-Fig. 3.2) from the motor support. Also

remove the transport bolts fitted next to the air receiver

supports.

7. Check the wires at transformer (T1-Fig. 1.9) for correct

connection, the settings of overload relay (F21) and circuit

breakers (Q25/26) 1), and that overload relay (F21) is set

for automatic resetting. See section 7.4.

8. Remove filler plug (6-Fig. 1.3). Pour approx. 1 l of oil into

the compressor elements. Reinstall the plugs.

9. Close drain valves (1 and 2-Fig. 3.4). 2)

10.For GR W, check that the cooling water drain valves 3) in

the inlet and outlet lines are closed and that the water shut-

off valves 3) are open. Open the water regulating valve (4-

Fig. 3.7) and check for water flow.

11. Check that the compressor is filled with oil: the pointer of

oil level indicator (5-Fig. 3.8) should be in the green range.

12.For GR Full-feature, check that valve (2-Fig. 1.2) is closed

and that valves (1 and 3-Fig. 1.2) are open.

13.For compressors provided with an OSD oil/water separator:

fill the vessel with water to the level of the water outlet and

re-install the cover.

14.Switch on the voltage. Start the compressor and stop it

immediately. Check the rotation direction of the drive motor

(M1-Fig. 1.1) while the motor is coasting to a stop. If the

rotation direction is wrong, switch off the voltage and

reverse two incoming electric lines.

The correct direction of rotation is indicated for the drive

motor by arrow (5-Fig. 1.1) and for the fan motors by arrows

(19-Fig. 1.3) on the motor housings.

3.2 Before starting

Attention

- The operator must apply all relevant safety precautions,

including those mentioned in this instruction book.

- In case the water system was drained (see section 3.7), close

the drain valves.

1. Switch on the voltage. Voltage on LED (2-Fig. 3.5) lights

up.

2. Close condensate drain valves (1 and 2-Fig. 3.4). 2)

3. Open air outlet valve (3-Fig. 3.3).

4. Check oil level indicator (5-Fig. 3.8): the pointer should be

in the green range or orange range 4).

5. For GR Full-feature (provided with an integrated dryer),

check that valve (2-Fig. 1.2) is closed and that valves (1

and 3-Fig. 1.2) are open.

6. On GR W open the water shut-off valves 3) and regulating

valve (4-Fig. 3.7).

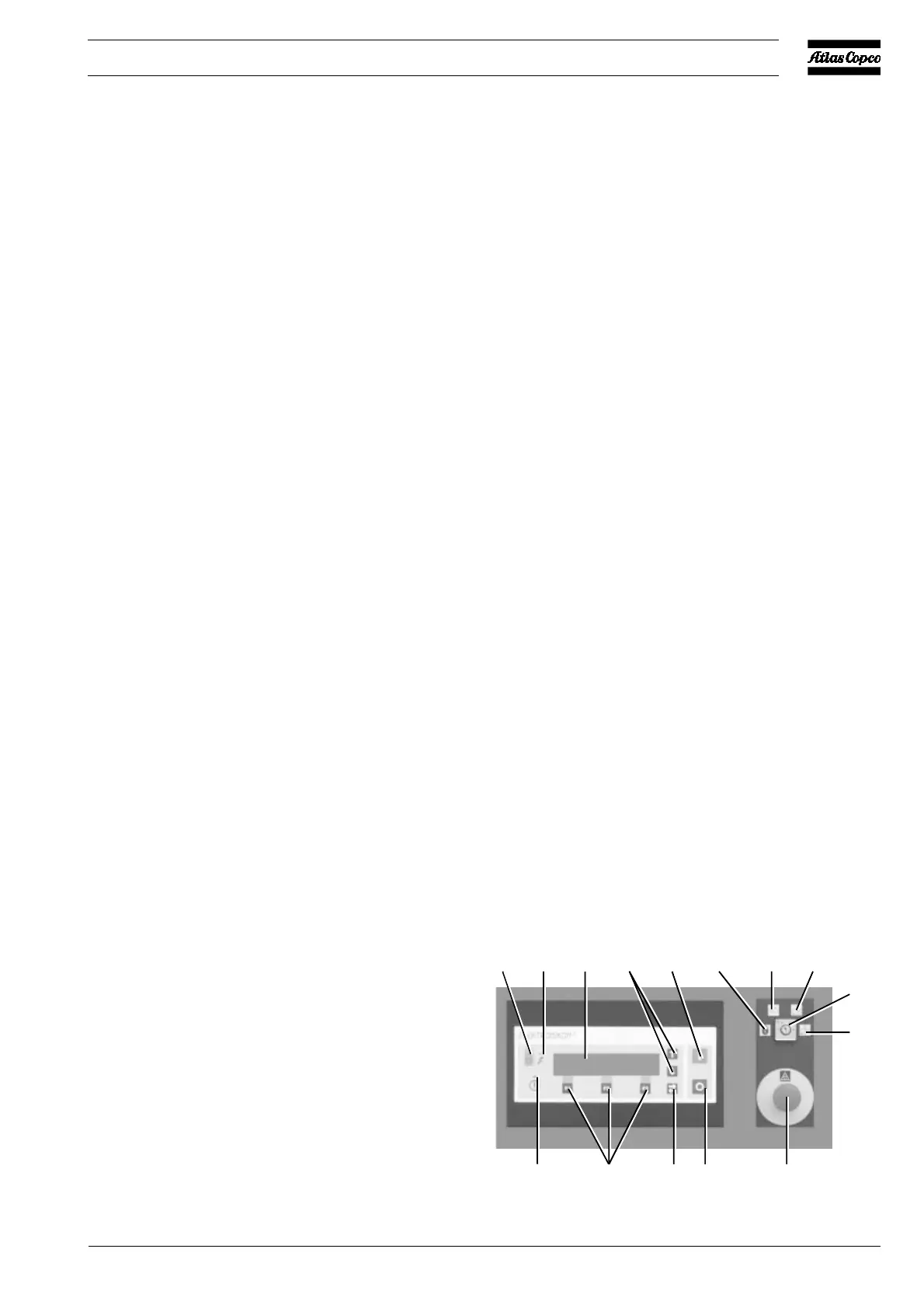

Fig. 3.5 Control panel

124

6

8

S5

S23579

50618F

10

11 12

13

Loading...

Loading...