Industrial Air Division

92920 5997 03

4 Maintenance

O-rings, washers. Consult Atlas Copco for available maintenance

kits.

The "longer interval" checks must also include the "shorter

interval" checks.

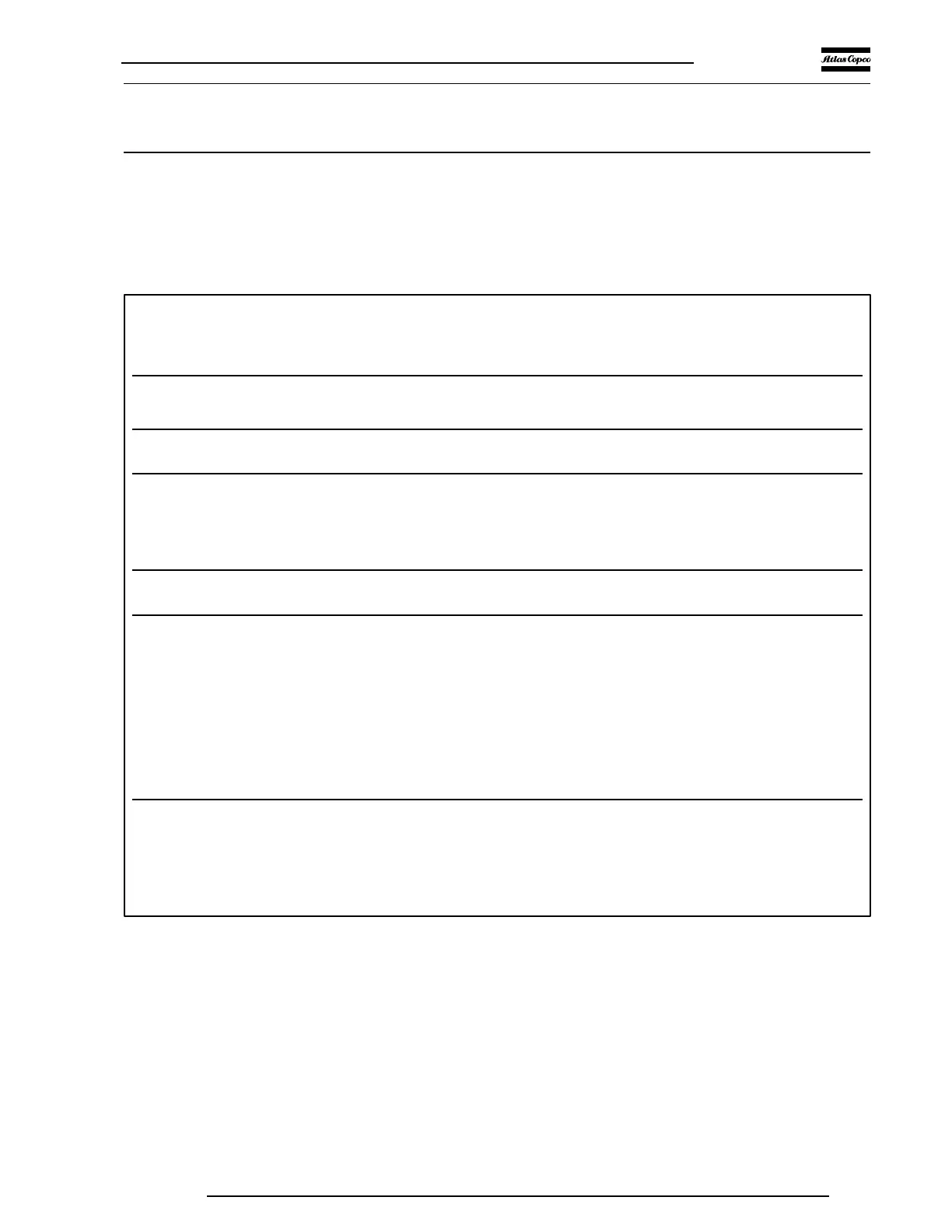

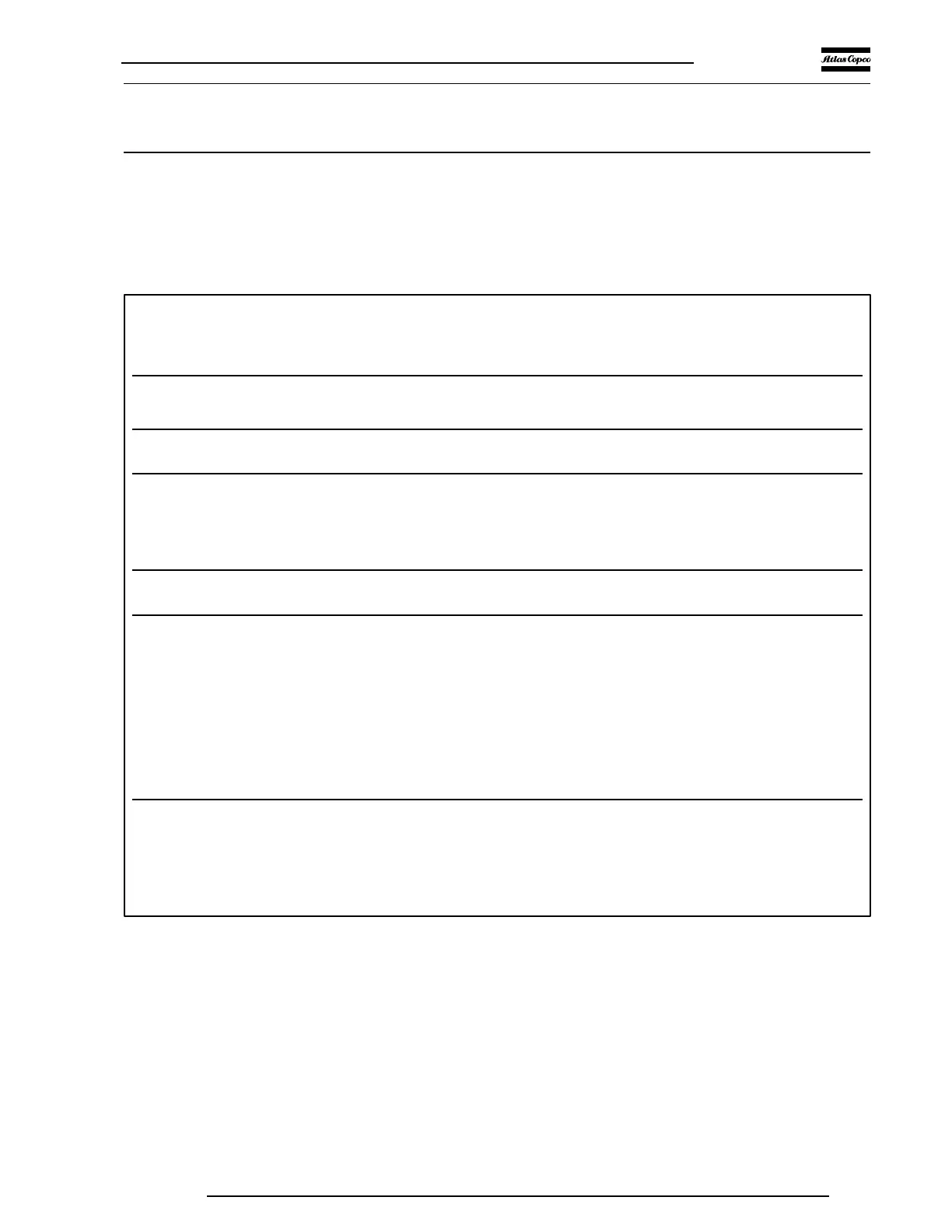

4.1 Preventive maintenance schedule

The schedule contains a summary of the maintenance instructions.

Read the respective section before taking maintenance measures.

When servicing, replace all disengaged packings, e.g. gaskets,

Period 1) Running Operation Consult See Preventive

hours 1) section note main-

tenance

kit No.

Daily ------ Check oil level (not on LEN) 3.2 1 --

Weekly ------ Drain condensate from air receiver by opening drain cock (10-Figs. 1) -- -- --

Monthly ------ Operate safety valve by turning its knurled cap or by lifting its central

plunger with a screwdriver -- 2 --

" ------ Check that regulating system operates properly -- -- --

" ------ Inspect air filter. Replace if necessary 5.3 4 2-Fig. 4

3-monthly ------ Clean unit. Remove dirt from cooling fins by air jet -- 3 --

Yearly ------ Test safety valve 5.5 -- --

" ------ If provided, test relief valve 5.6 -- --

" 400 On LE/LT9/12, replace air filter 5.3 4 2-Fig. 4

" 500 On LE/LT7/8, replace air filter 5.3 4 2-Fig. 4

" 700 On LE/LT5/6, replace air filter 5.3 4 2-Fig. 4

" 1000 Change muffler element on LE/LT7 up to -12 and LEN -- -- 2-Fig. 4

" 1000 Check tension of transmission belt(s) (if equipped with) -- 5 --

" 2000 Change oil if mineral oil is used (not on LEN) 4.2 -- --

" 2000 Inspect for carbon deposits in air receiver; clean if necessary -- -- --

2-yearly 3000 Change oil if Atlas Copco approved P.A.O. oil is used (not on LEN) 4.2 -- 5-Fig. 4

----- 3000 to Change check valve on LE/LT5/6 or unloader

4000 on LE/LT7 up to -12 and LEN 5.1 -- 3,4-Fig. 4

----- 4000 Change valves. For possible earlier replacement consult section 5.2 5.2 -- 1-Fig. 4

1) Whichever interval comes first. The local Sales Company may overrule the maintenance schedule, especially the service

intervals, depending upon the environmental and working conditions of the compressor.

Remark

For partial or complete overhaul, service kits, exchange compressors, etc. are available. Consult Atlas Copco.

Notes

1. Maintain the level in the lower half of the sight-glass.

2. Always wear gloves.

3. Wear safety glasses.

4. For normal operation in clean surroundings. More frequently when operating in dusty environment.

5. Correct adjustment is obtained when each V-belt can be pushed inwards 15 mm per m distance between the two pulley centres when

a force of 20 N is exerted midway.

Loading...

Loading...