15

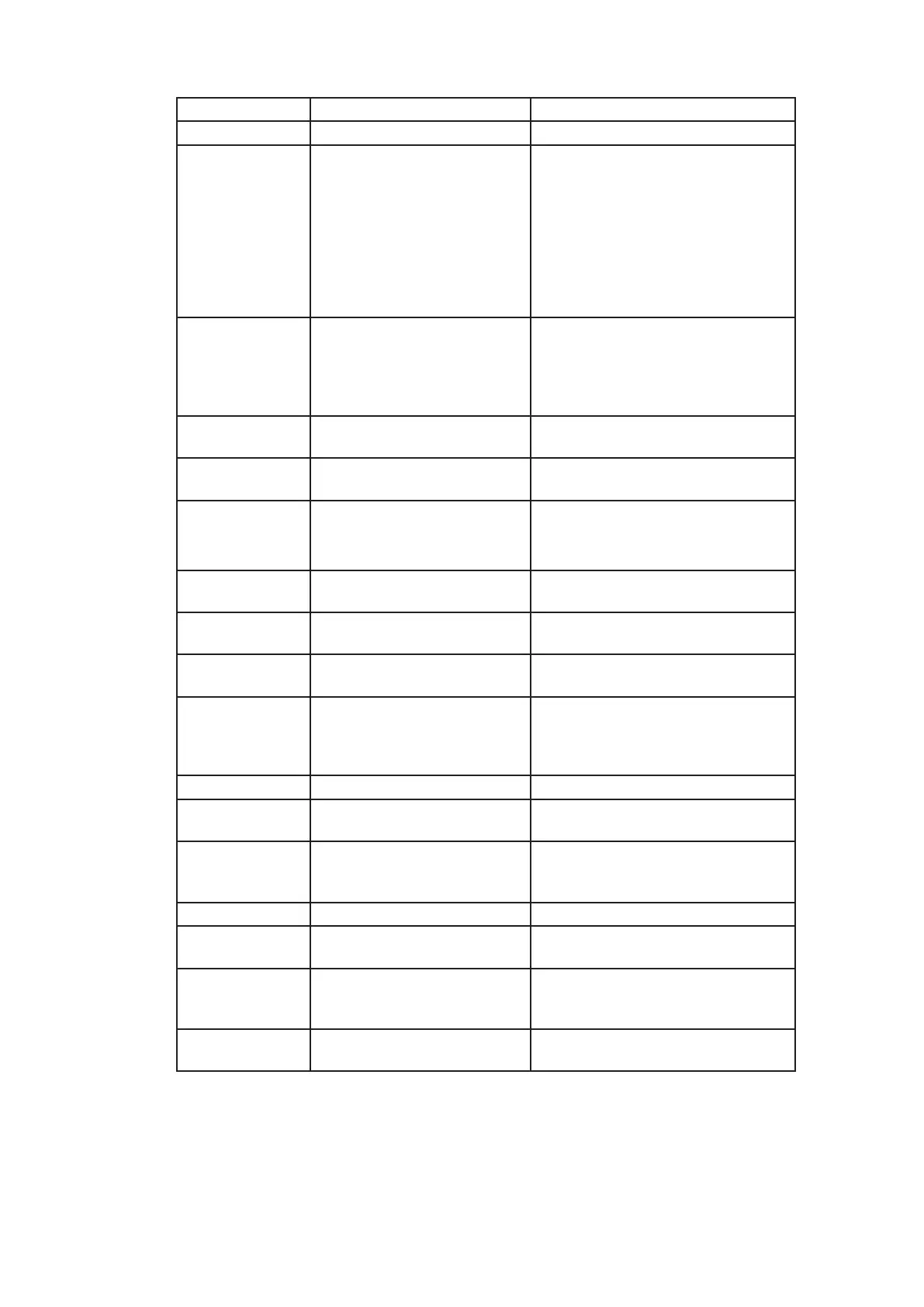

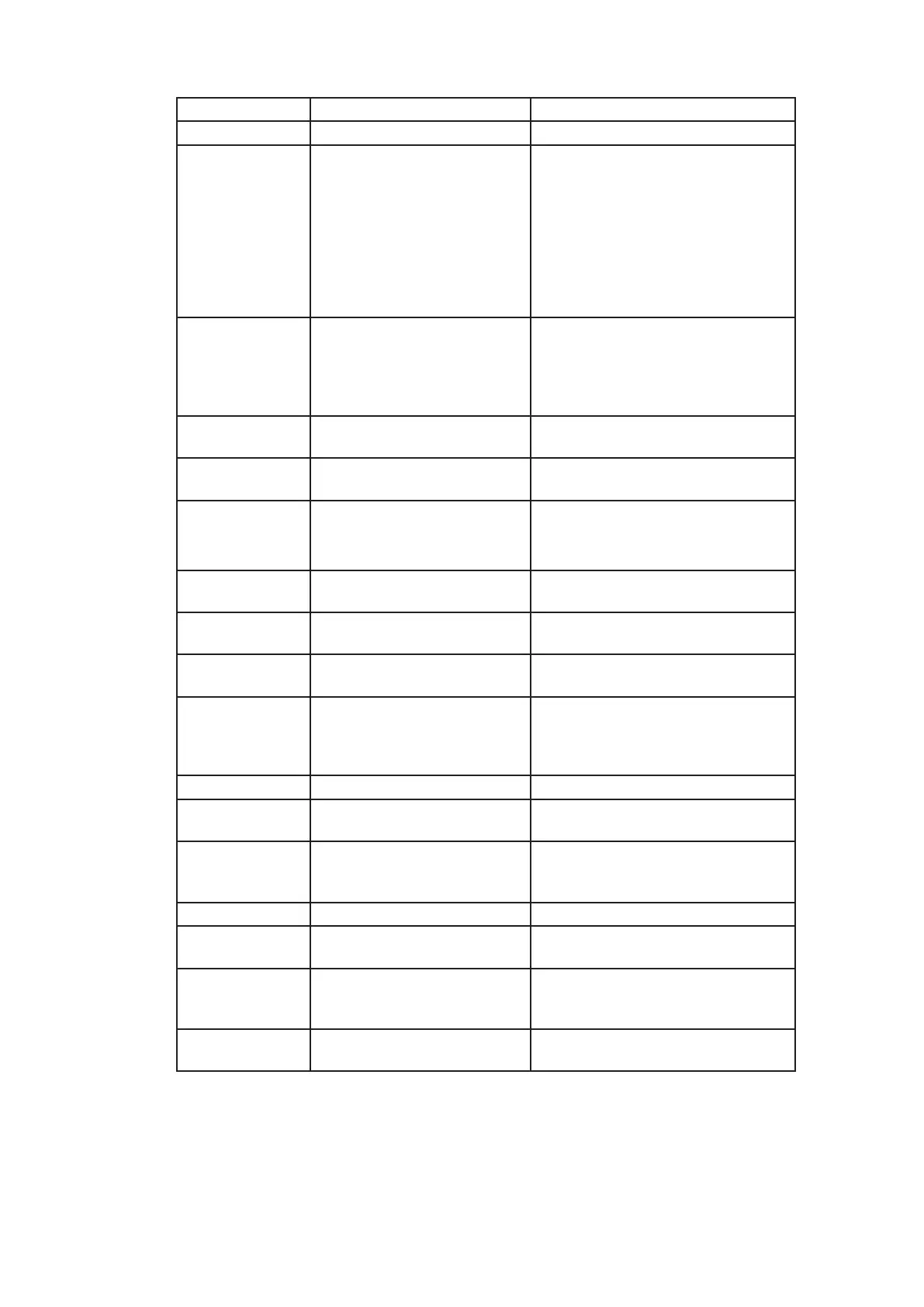

Problem Cause Solution

Uneven running

(continued)

The side bolts are unevenly

or insufficiently tightened.

Can cause the various parts

to lose their alignment,

resulting in the seizure of the

movable parts. Abnormal

strains on the side bolt

may result in fracture at the

threads.

Check and repair any damage to

the contact points and tighten the

bolts with the correct tightening

torque

The drill gets

hot

Lack of oil Add oil and check that it runs

through. It is not sufficient that

there is oil in the exhaust air. There

must also be an oil coating on the

shank of the working tool.

Freezing High level of humidity in the

compressed air

Use water traps

Water pressure higher than

the air pressure

Lower the water pressure

Water pipe

breakage

Misalignment of the shank Change working tool or shank

sleeve or both

Damaged flushing hole in

the shank

Change working tool

Chipping of the

piston tip

Misalignment of the shank Change the working tool or shank

sleeve or both

Excessive wear of the piston

tip

Change piston

Spline breakage

Lack of lubrication Lower the water pressure if it is

the same as or greater than the air

pressure

Increase lubrication or change oil

Dirt intrusion (specially

when drilling upwards)

Increase service intervals

Piston breakage

Lack of lubrication Lower the water pressure if it is

the same as or greater than the air

pressure

Increase lubrication or change oil

Uneven tension in the side

bolts

Tighten the bolts correctly

Worn guide sleeve/piston

guide (can be confirmed by

the cushion test)

Change the worn part

Side bolt

breakage

Uneven tension on the bolts Tighten the bolts correctly

15

Loading...

Loading...