Do you have a question about the Atlas Copco SRD 20 and is the answer not in the manual?

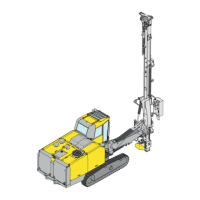

The SRD 20 and SRD 25 are pneumatic rock drills designed for vertical drilling, plug hole drilling, and drilling in concrete for construction and mining applications. They are not intended for any other uses.

The rock drill operates on a principle of impact, feed force, rotation, and flushing. The internal valve mechanism directs compressed air alternately to either side of the piston, causing it to move up and down. This piston then transmits energy through the drill steel to the bottom of the hole.

Rotation of the drill steel is achieved through a rifle bar mechanism, which turns the drill steel slightly with each blow. This rotation is anti-clockwise and occurs during the piston's return stroke. Flushing is an integrated feature, with flushing air ducted through a hole in the piston. This means that flushing air is provided as soon as the compressed air supply is activated.

Before operation, users must read and understand the safety and operating instructions to mitigate risks of serious injury or death. Only qualified and trained individuals who are physically capable of handling the machine's bulk, weight, and power should operate or maintain it. Personal protective equipment (PPE) is mandatory for operators and all persons in the working area, including a protective helmet, hearing protection, impact-resistant eye protection with side shields, respiratory protection (when appropriate), protective gloves, proper protective boots, and appropriate work overalls or similar clothing that covers arms and legs. The use of drugs, alcohol, or medication that impairs judgment or concentration is strictly prohibited.

Installation precautions include ensuring compressed air hoses and connections are undamaged and properly attached. Quick disconnect couplings at the tool inlet are not recommended; hardened steel threaded hose fittings should be used instead. If universal twist couplings (claw couplings) are used, lock pins and whipcheck safety cables are advised to prevent connection failure. Compressed air should never be pointed at oneself or others.

When handling insertion tools, it is crucial to ensure the tool retainer is in a locked position before starting the machine to prevent ejection. The insertion tool's shank must have the correct length, type, and dimensions for the machine to avoid it slipping out or being lost during operation.

Operating precautions emphasize avoiding explosive environments, flammable materials, fumes, or dust. Users should never drill in an old hole. Maintaining a stable position with feet shoulder-width apart and a balanced body weight is essential to counteract unexpected movements if the inserted tool breaks or gets stuck. The machine should always be held with both hands, and handles must be clean and free of grease and oil. Users should never grab or touch a rotating drill steel and should avoid wearing loose clothing, neckwear, or gloves that could get caught. Long hair should be covered with a hair net.

Dust and fume hazards are addressed by recommending site-specific risk assessments, using engineering controls like exhaust ventilation and dust collection systems, and wearing appropriate respiratory protection. Work should be conducted in well-ventilated areas, and exhaust should be directed away from dust-filled environments. Consumables and insertion tools should be selected, maintained, and replaced as recommended to minimize dust and fumes. Washable or disposable protective clothes should be worn, and showering and changing into clean clothes before leaving the worksite is advised to reduce exposure. Eating, drinking, or using tobacco products in dusty or fumed areas should be avoided, and hands and face should be washed thoroughly after leaving such areas.

The machine is not electrically insulated, so it must never be operated near electric wires or other sources of electricity. Users should check for concealed cables and pipes before drilling. If a concealed object is hit, the machine must be switched off immediately. Involuntary starts are prevented by keeping hands away from the start/stop device until ready to operate and learning how to switch off the machine in an emergency. The start/stop device should be released immediately in case of power supply interruption.

For SRD 20, starting involves opening the main valve, aligning the drill steel, slightly pressing the start/stop device for SOFSTART to gain grip, and collaring the hole with reduced feed force. Full power is activated by pressing the start/stop device all the way down. For SRD 25, the throttle lever is moved forward slightly to start percussion and rotation, collaring the hole with reduced feed force, and then fully forward once the drill steel has a secure footing. Stopping either model involves releasing the start/stop device, which automatically returns to the stop position.

Regular maintenance is crucial for the continued safe and efficient use of the machine. Before any maintenance, the machine should be cleaned to avoid exposure to hazardous substances. Only authorized parts should be used, as unauthorized parts can void the warranty and product liability. Mechanical parts should be cleaned with solvent in a well-ventilated area, adhering to health and safety regulations. For major service, contact an authorized workshop. After service, the machine's vibration level should be checked for normalcy.

Daily maintenance includes cleaning and inspecting the machine and its functions, checking for leaks and damage, and ensuring the air inlet nipple is tightened and the claw coupling is free from damage. The throttle handle and retainer functions should be checked, and damaged or worn parts replaced promptly. If equipped, the silencer should be checked for damage.

The wear in the chuck bushing should be checked daily using the Atlas Copco (3091 0038 00) gauge (22 mm). If the wear limit is exceeded, the drill steel shank will wear faster, leading to stoppages and increased drill-steel consumption. Hoses, couplings, and controls should be checked for leakage and damage. Lubrication levels should be checked, and the lubricator filled if necessary. The water separator should be drained.

Periodic maintenance, performed after approximately 100 operating hours or three times a year, requires dismantling, cleaning, and checking all parts. This work must be performed by authorized, trained staff.

The rock drill is lubricated with oil mixed with compressed air. An Atlas Copco BLG 30 or CLG 30 lubricator is used to meter oil into the air line. Atlas Copco Rock Drill AIR-OIL is recommended for its biodegradability and high film strength. If not available, a mineral-based air tool oil with appropriate viscosity grade for the ambient temperature should be used.

To prevent freezing, especially when ambient air temperature is 0–10°C (32-50°F) and humidity is high, Atlas Copco Rock Drill AIR-OIL and a VAM 5A water separator are recommended. If the drill freezes, it should be allowed to thaw at room temperature; heating or pouring methylated spirits into it is prohibited as it can interfere with lubrication and increase wear.

Air pressure should be 4-6 bar (58-87 psi). High pressure causes rough operation and excessive wear, while low pressure results in slow drilling. The correct air pressure should be calibrated using an Atlas Copco (9090 0550 80) pressure gauge, measured near the inlet nipple, with the rock drill running. The recommended operating pressure is 6 bar (87 psi).

For storage, the rock drill should be well-oiled, stored in a clean and dry place, and protected from foreign matter. The chuck should be protected with a plastic or wooden plug or clean cotton waste. For long-term storage, oil should be poured directly into the air intake, and the air turned on briefly to protect against corrosion.

Disposal of a used machine should be done in a way that maximizes recycling and minimizes environmental impact, adhering to local restrictions.

| Category | Drill |

|---|---|

| Manufacturer | Atlas Copco |

| Model | SRD 20 |

| Max. Hole Diameter | 20 mm |

| Power Source | Compressed Air |

| Type | Rock Drill |

| Operating Pressure | 6.3 bar |