SRD 25

1. Pull the throttle lever (A) backwards to the

closed position, this will stop the percussion

and rotation.

Operating

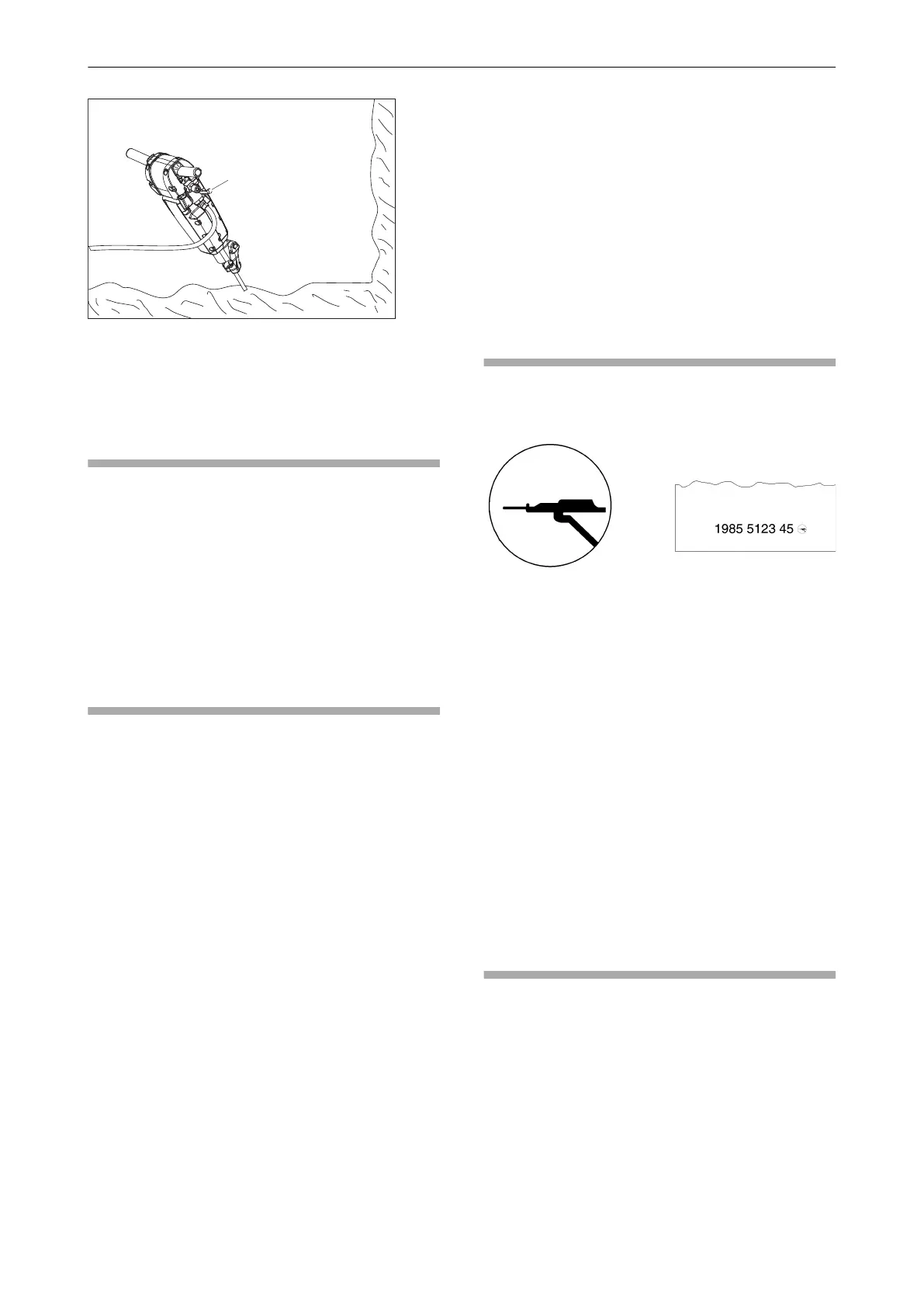

Drilling

◆

Use protective shoes, gloves, helmet, ear

protectors, impact resistant eye protection with

side protection and respiratory protection.

◆

Stand firmly and always hold the machine with

both hands.

◆

Hold the inserted tool firmly against the work

surface before starting the machine.

When taking a break

◆

During all breaks you must place the machine

in such a way that there is no risk for it to be

unintentionally started. Make sure to place the

machine on the ground, so that it can not fall.

◆

In the event of a longer break or when leaving

the workplace: Switch off the power supply and

then bleed the machine by activating the start

and stop device.

Maintenance

Regular maintenance is a basic requirement for

the continued safe and efficient use of the

machine. Follow the maintenance instructions

carefully.

◆

Before starting maintenance on the machine,

clean it in order to avoid exposure to hazardous

substances. See “Dust and fume hazard”.

◆

Use only authorised parts. Any damage or

malfunction caused by the use of unauthorised

parts is not covered by warranty or product

liability.

◆

When cleaning mechanical parts with solvent,

comply with appropriate health and safety

regulations and ensure there is satisfactory

ventilation.

◆

For major service of the machine, contact the

nearest authorised workshop.

◆

After each service, check that the machine's

vibration level is normal. If not, contact the

nearest authorised workshop.

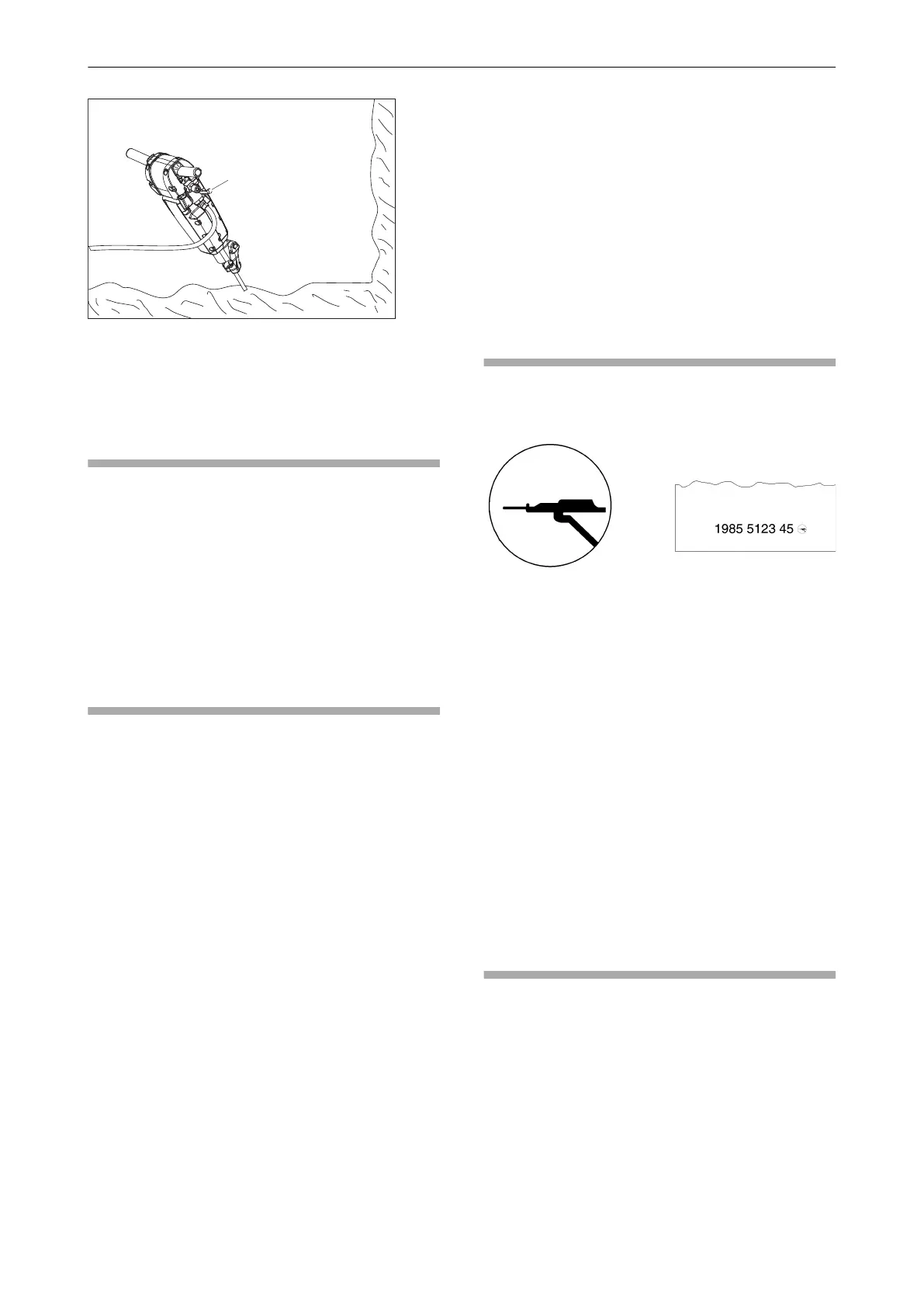

Differences between original

parts and pattern parts

When buying a part, the first thing to do is to verify

that the part is an Atlas Copco part. Most parts can

be identified.

Rock drill parts are normally marked with a part

number and the Atlas Copco identity mark which is

a circle with a rock drill. In a few cases the part is

marked either with the circle only or the part

number only.

Rubber and plastic parts are not normally marked.

Competitors that copy our parts often mark major,

expensive parts. Some parts have only the part

number, but some of them also have an identity

mark in the form of the initials of the

manufacturer's name. Part numbers on the pattern

parts are mostly stamped by hand which results in

irregularities. The part numbers stamped by Atlas

Copco are regular and the individual figures are

the same size. In addition the depth of the figures

and the spacing between the figures in each group

are the same.

Every day

Before undertaking any maintenance or changing

the insertion tool on pneumatic machines, always

switch off the air supply and bleed the machine by

depressing the start and stop device then

disconnect the air hose from the machine.

◆

Clean and inspect the machine and its functions

each day before the work commences.

◆

Conduct a general inspection for leaks and

damage.

SRD 20, 25 Safety and operating instructions

© Construction Tools PC AB | 9800 1883 01 | 2017-05-31

Original instructions

17

Loading...

Loading...