PennEngineering • www.pemnet.com 39

Instruction Manual - RIV938

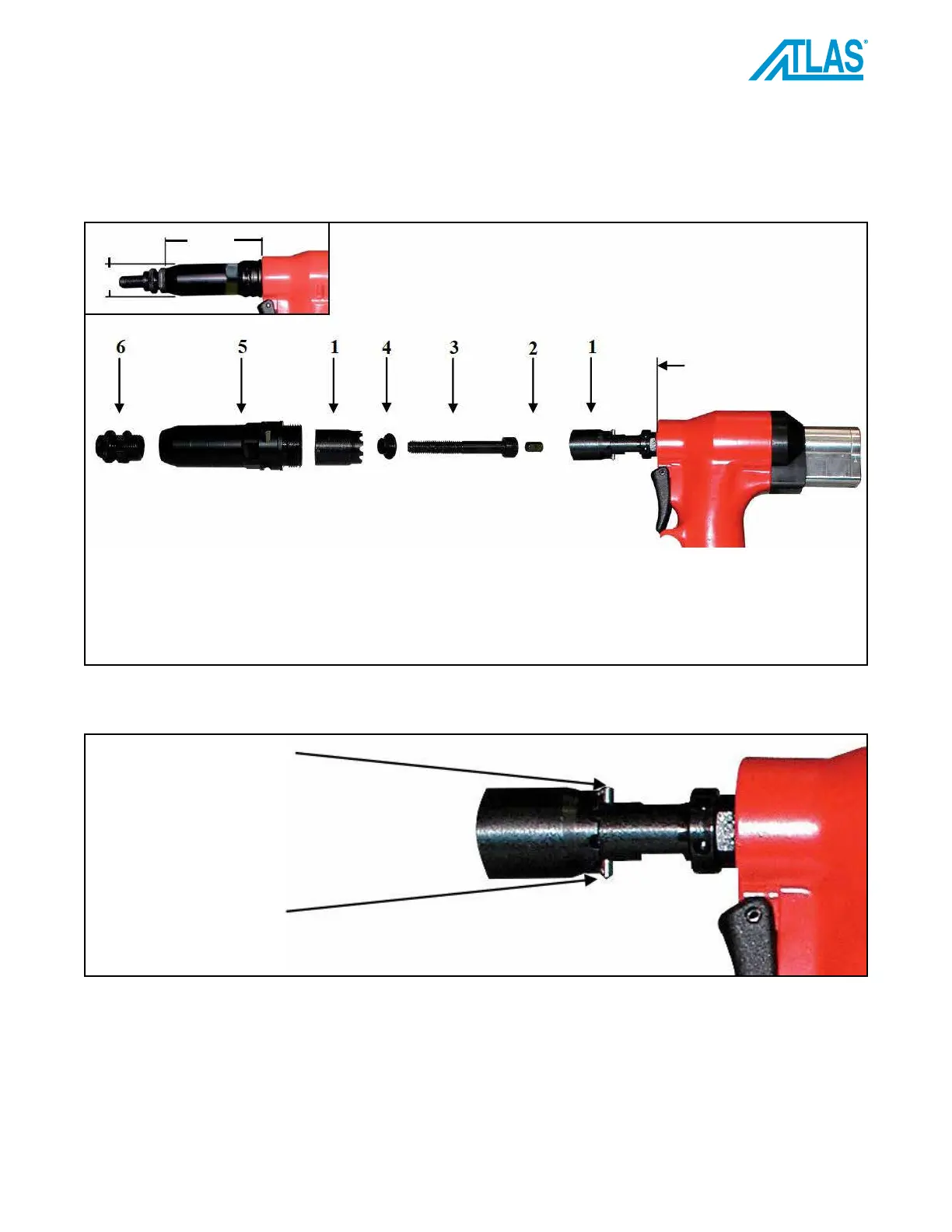

TOOL PREPARATION AND SCREW REPLACEMENT

Warning: Tool setting and screw replacement must be carried out with the tool disconnected from the air supply

line.

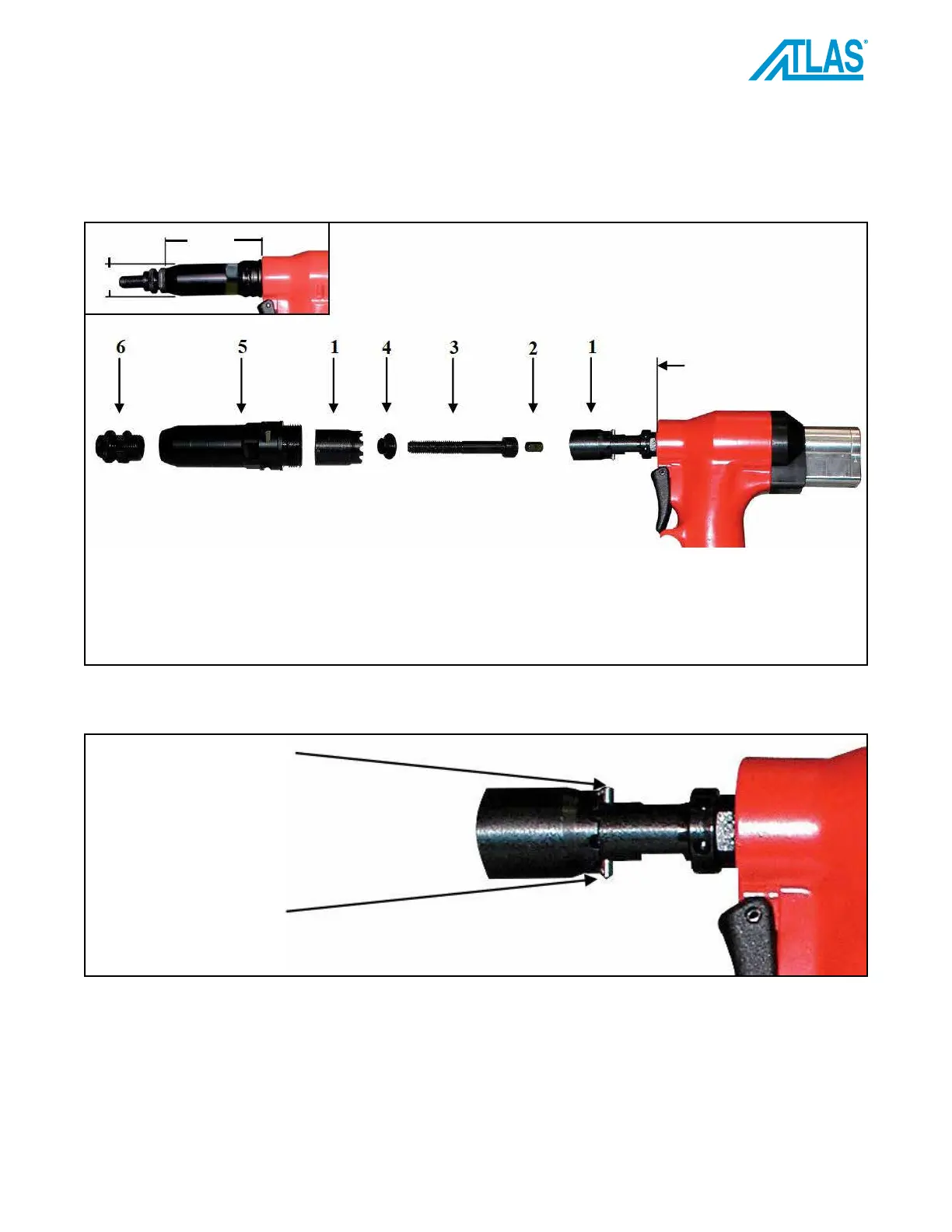

Simultaneously press

the two pins sliding

them into the hole and

unscrew the ring.

There must be a distance

of .060” / 1.5 mm

between the casing

and the nut for motor

screwing.

Ø 1.02” /

26 mm

2.76” /

70 mm

To replace screws you have to carry out the following operations:

Unscrew the toothed ring 1 from the tool. Insert joint 2. Insert screw 3. Insert screw adapter 4.

Screw the toothed ring 1 making sure that the screw (or tie rod) moves freely, then try and find

the most suitable joint (see indented ring). Screw on 5 and 6.

TO UNSCREW THE KIT HOLDER QUICK RING

Loading...

Loading...