INSTALLATION-MANUAL

4-Colomn

AL3044

AL4044

AL4044/VS

AL4044/VANS

AL5044

AL5044/T

ISSUED 22-7-2008

AUTEC Hefbruggen bv

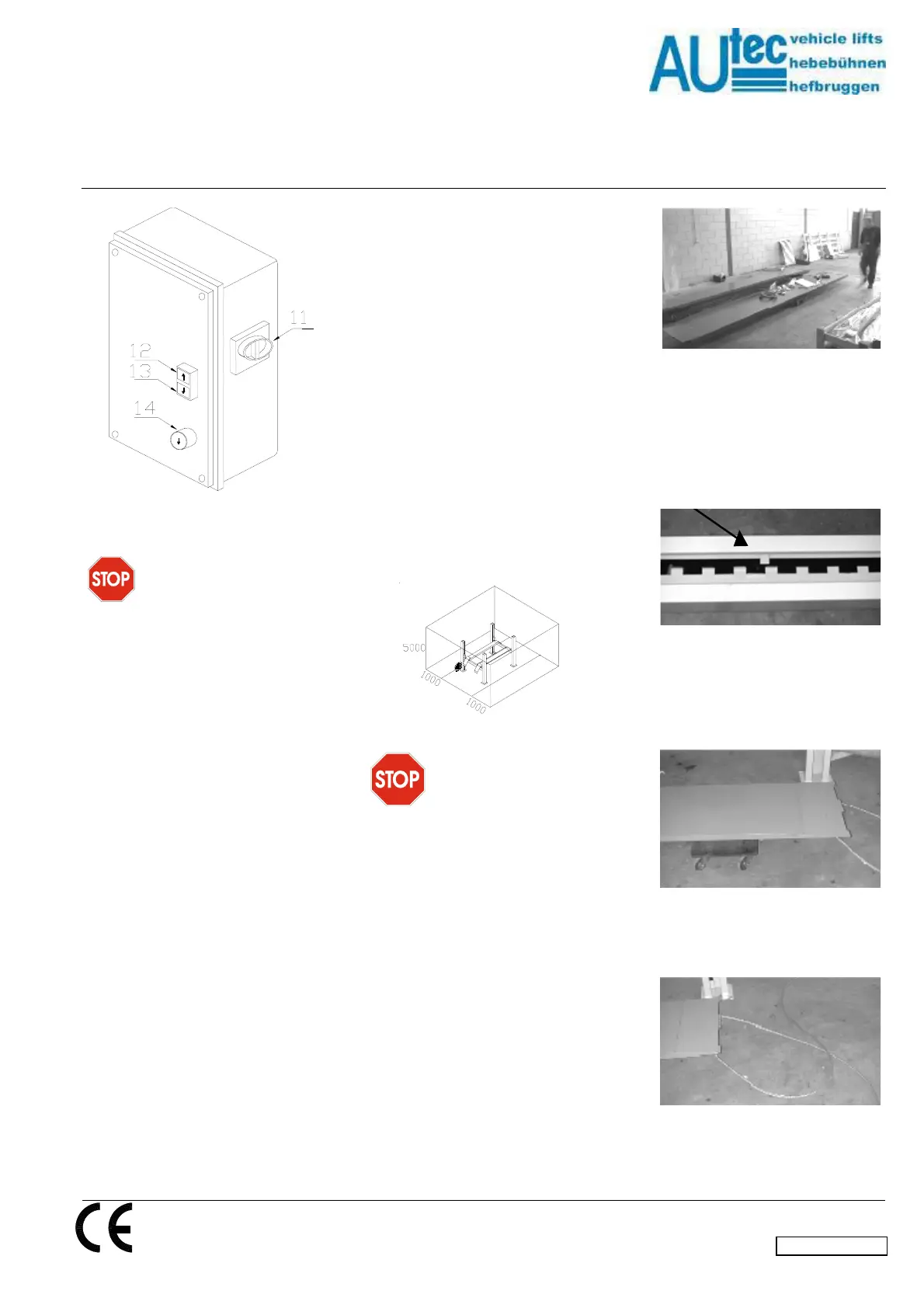

Fig.3

5. INSTALLATION

Installation may only be done

by persons authorised to do so.

BEFORE STARTING INSTALLATION,

PLEASE RECHECK ALL

THE

CONTROL POINTS.

The lift must be installed in an enclosed

space where weather

influences do not

have any effect. The place of installation

must be at a sufficient distance from the

storage locations of paint and wax, and

also rooms where there is a danger of

explosion.

ELECTRICAL POWER SUPPLY

POINT.

The client must ensure that there is a

power

supply point near the installation

site, which satisfies all the applicable

legal requirements (see page 4). If such

power supply is not available, the

installation technician will arrange for

an emergency cable. The lift shall be

tested after the emergency power

supply has been dismantled. The client

must then arrange for a duly qualified

and recognised installation technician to

lay the final wiring.

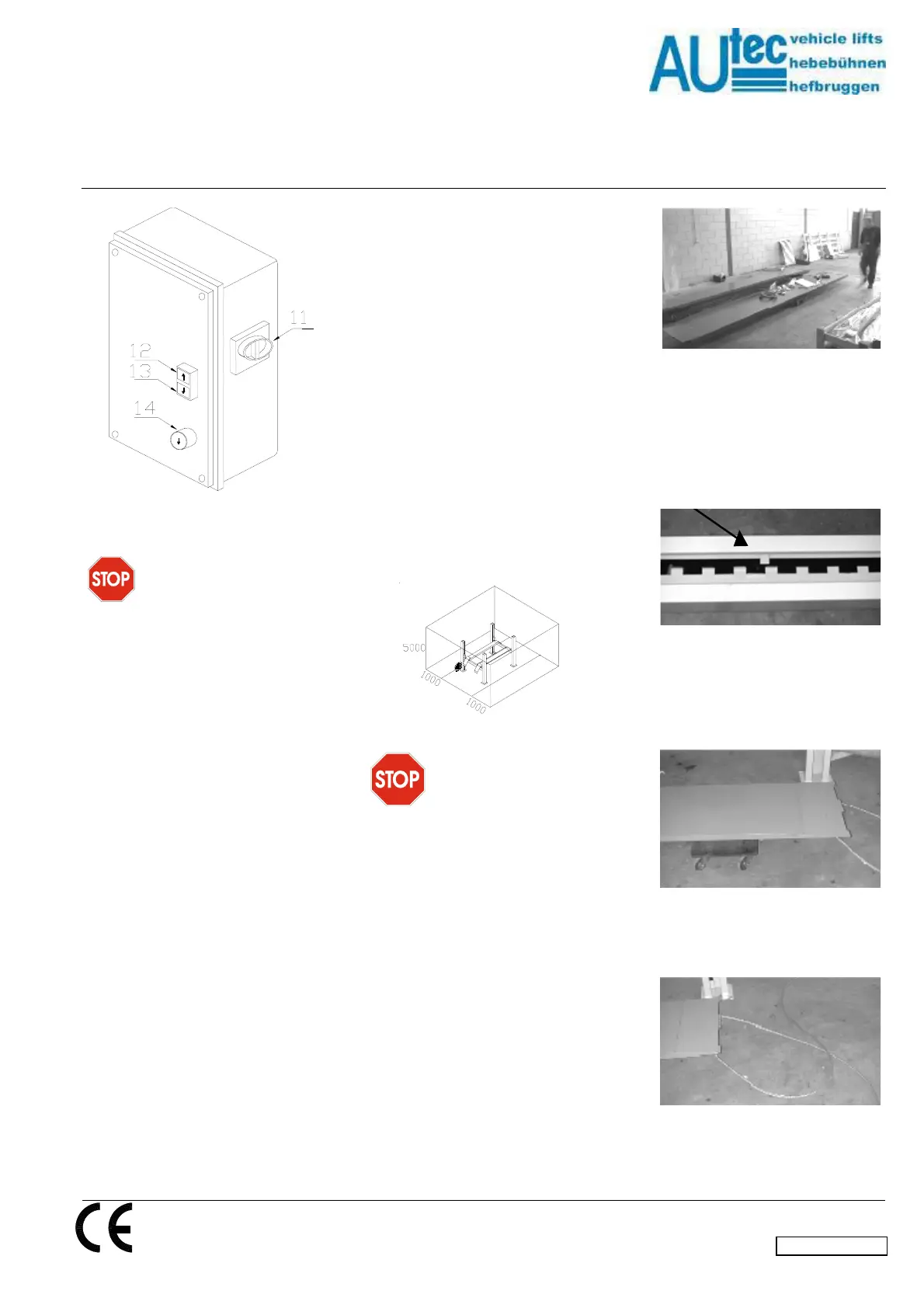

IMPORTANT INSTALLATION

MEASURES

The lift must be installed taking into

account

the dimensions of other objects

(Fig. 4), and the rules and regulations

applicable in the country where the lift is

installed.

In particular, attention should be paid to

the following :

The

minimum height from the floor,

at the installation location, must be

5000 mm

The minimum distance from the

walls must be 1 m.

The minimum working area is 500

mm

Adequate room for working

Adequate room for

maintenance,

access-/ and exit routes.

Position with respect to other

machines

In the neighbourhood of

the power

supply point to ensure problem-free

connection.

Fig.4

During the installation no

unauthorized persons may be

present in the safety zone around the

lift.

• Remove

the packaging from the

driving plates.

Place the driving tracks on dollies and

convey

them to the general location of

installation. The driving track with the

cabling / hydraulics under the driving

plate must be installed on the same side

as the operating column (fig. 5)

Fig.5

Open the packaging of the columns and

place

the columns on the installation

location. Fit the locking strips in the

columns. Take care: that this strip runs

behind the strip (1) in the centre of the

column (Fig.6).

Fig.6

Place the crossbeams on dollies. Take

care:

that the crossbeam with the fuse

box is placed on the same side as the

operating column (Fig.7).

Fig.7

Remove the steel cable from under the

driving plate (Fig.8).

Fig.8

Lead the cables to the non-operating

side through the crossbeam. The cable

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel:+31 348 477000 Fax:+31 348 475104 E-mail: info@autec.nl

en/TD-AL4044-03

Loading...

Loading...