32

745/750

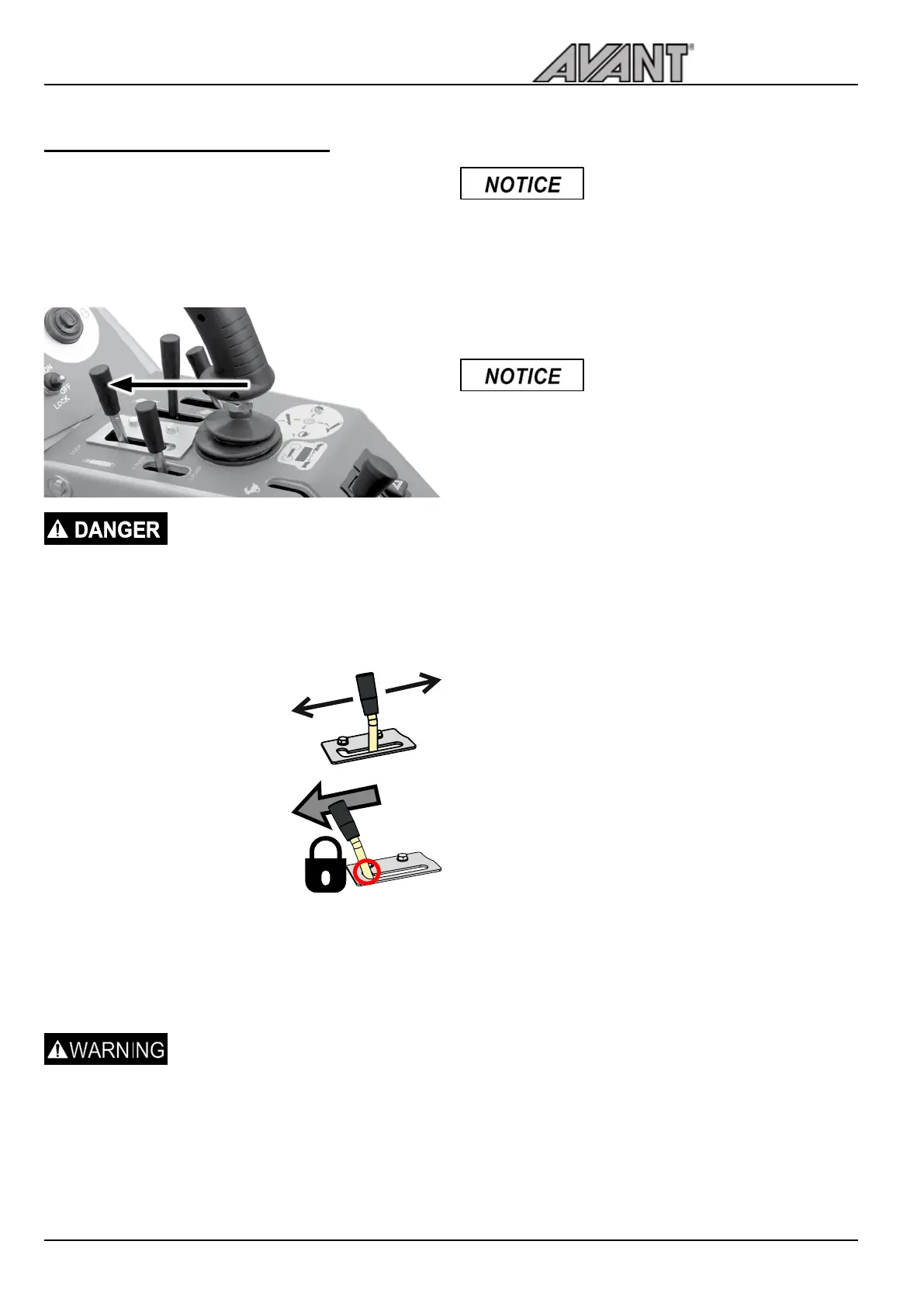

Using the auxiliary hydraulics

Auxiliary hydraulics (hydraulically operated attachments)

are controlled with the control lever on the control panel

front from the joystick, or with the optional auxiliary

hydraulic control buttons on the joystick. The lever locks

in the locking position (on the forward) which facilitates

operation of the attachments that require constant oil ow

to operate (rotary broom, backhoe etc.).

Hazards related to attachments -

Going near an attachment that is in

operation can cause a serious risk.

Switch off auxiliary hydraulics before

leaving driver’s seat or stopping the

engine. Operate the controls only

when sitting in the driver’s seat.

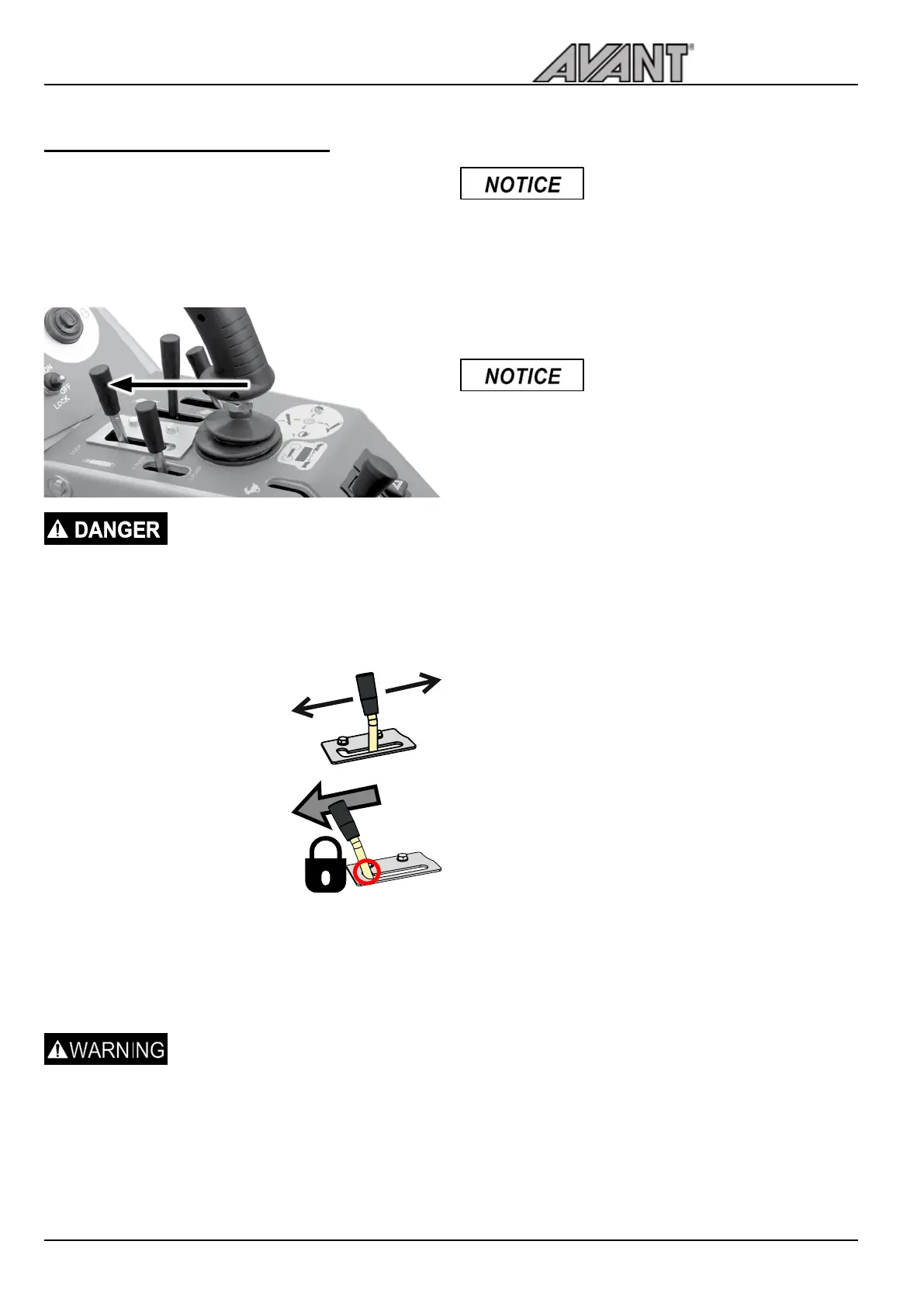

• Operation directions depend

on the attachment used.

• When using an attachment

for the rst time, carefully

move the lever to test and

check the operating direction

of the attachment.

• For continuous operation of

rotating attachments, turn to

direction 1 and turn to locking

position.

You can use either this lever or the buttons of the electric

joystick (optional equipment) to operate the the attachment.

Release the lever to its neutral position when you stop

using the loader.

Avoid unintended movements

of the attachment - Release

the control lever to its neutral

position. If the lever is locked on,

the attachment may move during

start of the loader. Make sure to

release the lever, and to follow the

Safe stopping procedure.

Make sure that the auxiliary

hydraulics control lever will lock

in its fully engaged position when

locked on. Even a slightly incorrect

position is enough to decrease

the effectiveness of the hydraulic

system, and will cause overheating

of the hydraulic oil. Adjust the

locking plate if needed.

If the pump selection lever is at the

2-pump setting, the loader may

stall when running on low rpm.

Keep the lever normally in 1-pump

setting. Use 2-pump setting only

with attachments that require

high ow of auxiliary hydraulics.

See the operator’s manual of the

attachment.

Operating instructions

1

2

Loading...

Loading...