7. Handling & Adjustment

The following adjustment procedure should be taken after completion of all piping and electrical

wiring.

Note: Following procedures are mainly used for the MC9 models with D04 Filter-Regulator

integrating solenoid valve or D14 Regulator integrating solenoid valve. But, in case of the

models without supply air control equipment such as above D04 Filter-Regulator or D14

Regulator, handle the equipment equivalent to above equipment for adjustment.

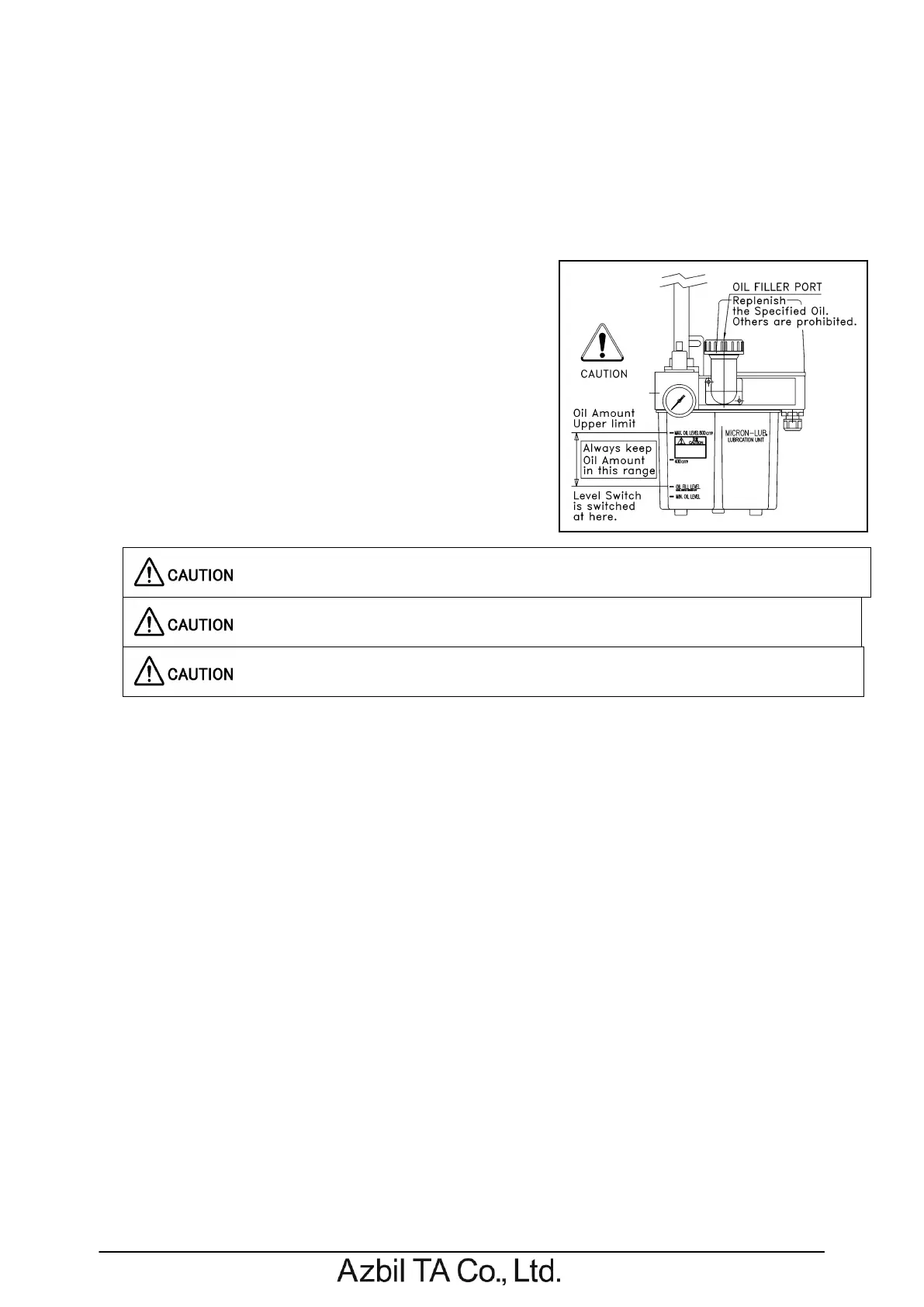

7-1. Oil replenishment

・Before supplying electricity and air pressure to the

Micron-Lub lubrication unit, fill oil up to maximum oil level

of the reservoir. If the pump is actuated without lubricant

in the reservoir, the pump inhales air bubble, which

breaks feeding oil to the venturi-nozzle.

・Recommended lubricants grades are ISO VG32~68 and

should be suitable for mist lubrication. It is recommended

to use the lubricants recommended by machine

manufacturer and/or bearing maker.

・Consult to the lubricant makers or Azbil TA if it is unclear

that the lubricant is suitable for Micron-Lub lubrication.

・Do not actuate the pump on the condition that there is no lubricant in the reservoir.

・Confirm there is oil level over min. level in the reservoir.

・Do not replenish lubricant exceeding the max. oil level of reservoir.

・If overfilled, oil may splash from the bleeder tube.

・Use the lubricant that is suitable for the mist lubrication (Micron-Lub lubrication).

・Others would damage the lubricated parts.

7-2. Air supply

・Before supplying air to Micron-Lub lubrication unit, make certain that the adjustment of Regulator

section being fully released. And a stop valve, if installed in the air supply side, should be

opened.

・After this, activate solenoid valve (SOL) of the Regulator section first, and then turn the regulator

adjustment knob clockwise in order to set the operating pressure of the Micron-Lub lubrication

unit. Set operating pressure can be read on pressure gauge of the Filter-Regulator or of

Regulator.

・Operating pressure range of Micron-Lub lubrication unit is 0.15 to 0.35MPa

Note: (1) D04 Filter-Regulator with solenoid valve or D14 Regulator with solenoid valve can

adjust pressure only while the solenoid valve is being activated.

(2) Minimum operating pressure of automatic drain mechanism of D04 Filter-Regulator is

0.1MPa.

If supply pressure is under 0.1MPa, air leaks from the drain port of filter section would

happen.

7-3. Adjustment of operating pressure and manifold pressure

・Energize the solenoid valve (SOL) of D04 Filter-Regulator or of D14 Regulator in order to adjust

operating pressure and manifold pressure.

・The by-pass air adjusting screw can adjust manifold pressure higher, thus air flow amount to the

Fog-Nozzles will be increased. This will give better air cooling effects to the lubricated parts.

However as first stage by-pass air screw adjustment, manifold pressure must be set at 0.05MPa,

as the every lubricated element has each heat generative factors. Then, with checking the

temperature increment at lubrication part, increase manifold pressure gradually for the best

manifold pressure. Max. manifold pressure is 0.25MPa.

Loading...

Loading...