WWW.BALTIMOREAIRCOIL.COM

12

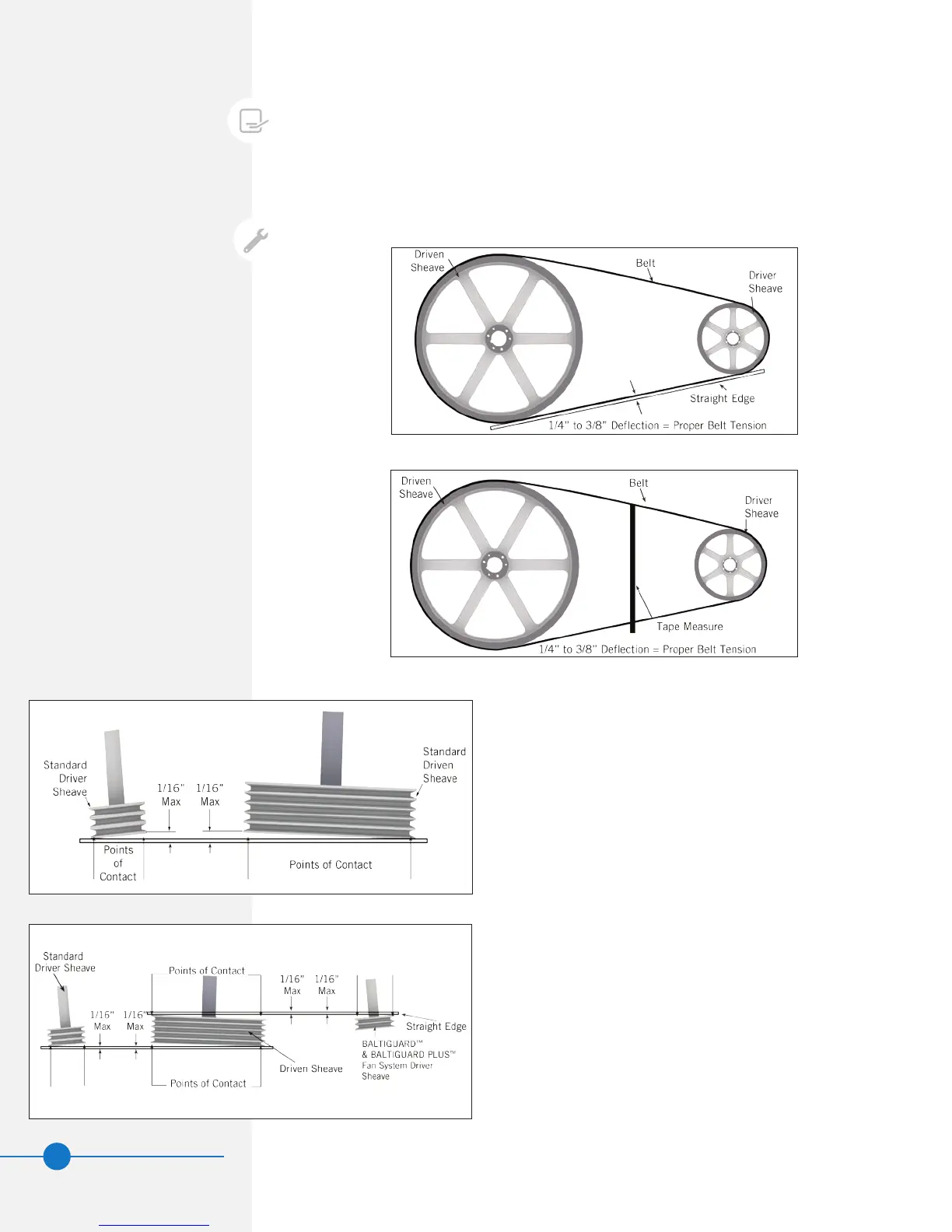

• Belt tension check:

– PlaceastraightedgealongthebeltfromsheavetosheaveasshowninFigure 3a,or

useatapemeasureasshowninFigure 3btomeasurebeltdeection.

– Applyamoderateforcebyhand(approximately40lbs/275kPa)evenlyacrossthe

widthofthebeltinthecenterofthespanbetweenthesheaves.

– Thereisadequatebelttensionifthebeltdeectsbetween1/4”and3/8”asshown

in Figures 3aand3b.

NOTE: If belts are properly

tensioned, there should be no

“chirp” or “squeal” when the fan

motor is started.

ATTENTION: Check to ensure the

controls for the fan motor are set

to allow a maximum of six on-off

cycles per hour to prevent motor

overload.

Figure 3a. Belt Tension with a Straight Edge

Figure 3b. Belt Tension with a Tape Measure

• Belt tension adjustment (if required):

– Loosenthelocknutonthemotorbaseadjustingscrew.

– Turnthemotorbaseadjustingscrewclockwiseto

tensionthebeltorcounterclockwisetorelievebelt

tension.Duringadjustmentofthebelttension,rotate

thedrivesseveraltimesbyhandtoevenlydistribute

thetensionthroughoutthebelt.

– Whenthebeltisproperlytensioned,retightenthe

lockingnutonthemotorbaseadjustingscrew.

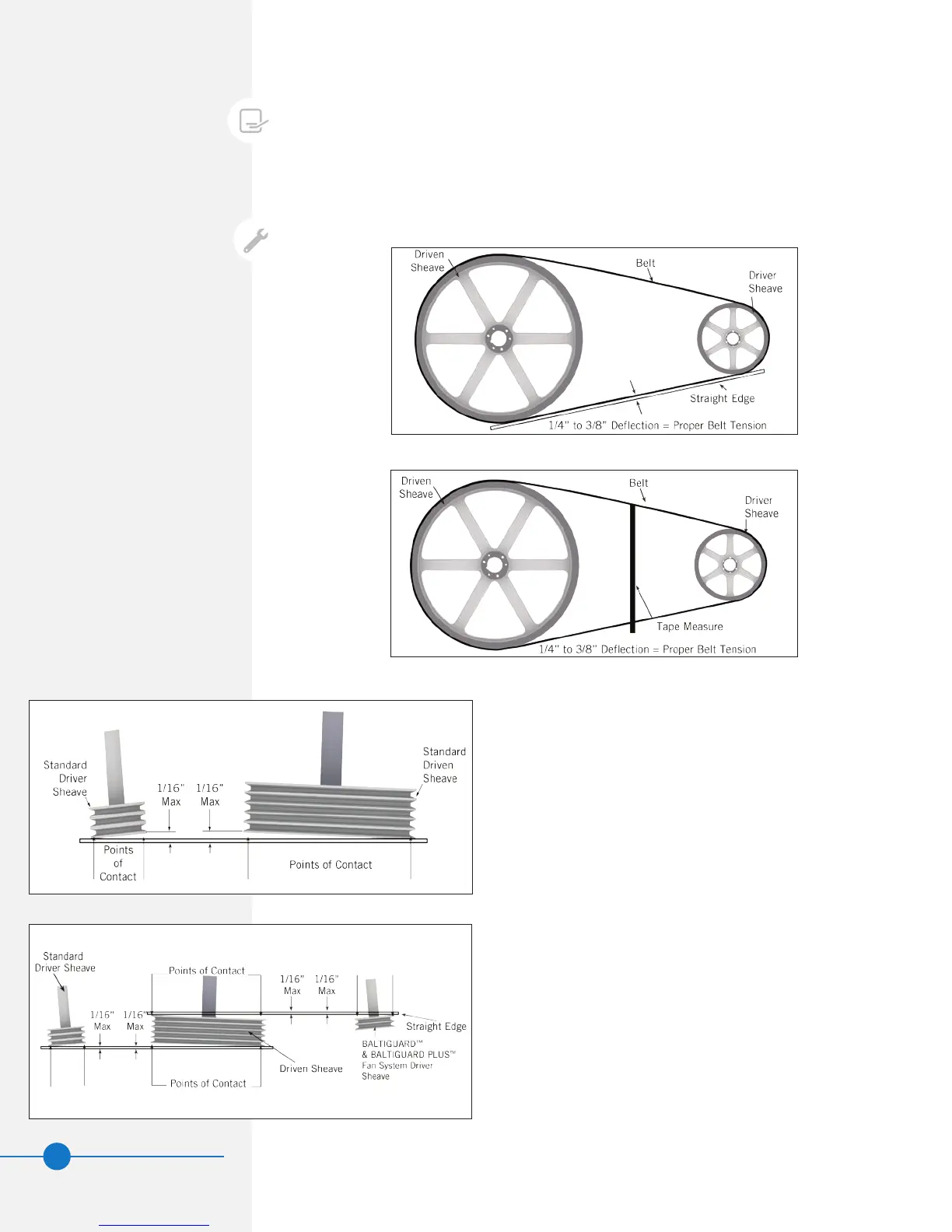

• Drive alignment check and adjustment:

– Checkthedrivealignmentannuallytoensure

maximumbeltlife.

– Placeastraightedgeacrossthedriverandthedriven

sheavesasshowninFigure 4a forstandarddrivesand

inFigure 4bfortheBALTIGUARD™FanSystemorthe

BALTIGUARDPLUS™FanSystem.

– Thestraightedgeshouldcontactallfourpointsas

showninFigure 4aindicatingthatthedrivesare

properlyaligned.

– Thereshouldbenomorethan1/16”deviationfrom

thefourpointsofcontact.

– Incaseofrealignment,loosenthemotorsheave,and

alignitwiththefansheave.Allow1/4”fordraw-upas

thebushingscrewisretightened.

Figure 4a. Standard Drive Alignment

Figure 4b. BALTIGUARD™/BALTIGARD PLUS™ Fan System Drive Alignment

Loading...

Loading...