WWW.BALTIMOREAIRCOIL.COM

13

Detailed Component

Maintenance

Procedures

Fan Drive System

BALTIDRIVE

®

Power Train/

BALTIGUARD™ and

BALTIGUARD PLUS™ Fan

System

Optional Gear Drive System

Optional Gear Drive System

Initial Start-Up

• Iftheunitisequippedwithanextendedlubricationlineoptionorexternalsightglass,

makesuretheballvalvelocatedatthegearboxisopenpriortostart-up.

• BACshipsallgeardriveslledwithoil.Theinitialoillevelshouldbeatornearthe

middleoftheoillevelsightgauge.

• Internallymountedgeardrivesarefactoryinstalled,aligned,andtightened.Double

checkallgeardrivefastenersaftertheunithasbeeninstalled.

• Onunitswithexternallymountedmotors,installandalignthemotoranddriveshaft

inaccordancewithBAC’sinstallationinstructions.Recheckthealignmentandall

externalfastenersaftertwoweeksofoperation.

• Oninstallationswithvariablefrequencydrives,donotoperatethestandardgeardrives

below450RPMmotorspeed(gearinputspeed).Forspeedslessthan450RPM,a

lowspeedoptiongeardrivemustbesupplied.

• Priortothestart-up,checkallttingsonthegeardrivetoensurethatthereareno

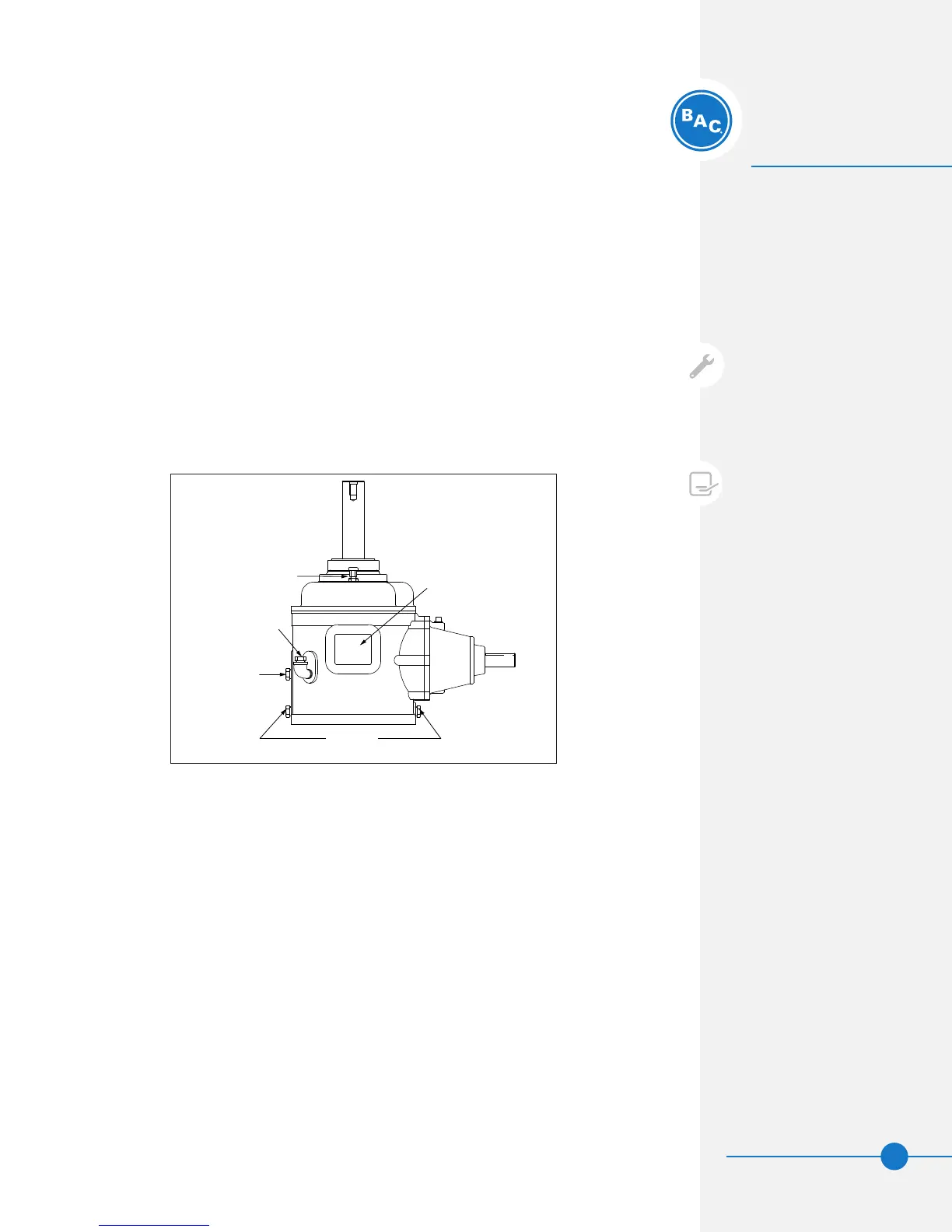

visibleleaks.RefertoFigure 5 forlocationsofthegeardrivettings.

Change Interval

• Initial oil change:Replacetheoriginaloilafter500hoursorfourweeksofoperation,

whichevercomesrst.

• Aftertheinitialoilchange,changetheoilevery2,500hoursorsixmonths,whichever

comesrst.

• Draintheoilatoperatingtemperaturethroughthedrainplug.

• Rellthegeardrivethroughtheoilllelbowwiththerecommendedtypeandamount

oflubricant(Table 3, page 15).RefertoFigure 5forlocationsofthesecomponents.

Inspection & Maintenance

• Maintaintheoillevelatornearthemiddleoftheoillevelsightgauge.Theoillevel

shouldalwaysbevisibleinthesightgaugewindowwhentheunitisnotoperating/

energized,andtheoilisatambienttemperature.

• Checkoillevelweeklywiththeunitidle.Onunitssuppliedwithanexternalsight

gauge,checktheoilleveloftheexternalsightgaugeandthesightgaugeonthegear

drivetoensurethattheproperamountofoilisinthegeardrive.

• Addoilthroughtheoilllelbowiflevelisbelowtheoillevelsightgauge.

• Thestandardoilprovidedismineraloil.Syntheticlubricantsarealsoavailableasan

option(seeFanDriveSystem“Lubrication”onPage 15).

ATTENTION: Gear drives should

not be used with Wye-Delta (Y-)

motors.

Air Breather Plug

Oil Level

Sight Gauge

Oil Drain Plug

Oil Fill Elbow

Name Plate

Figure 5. Gear Drive

NOTE: Continued operation at a

speed which resonates with the

gear drive system may result in

torsional vibrations which can

damage system components. The

most common indicator of torsional

vibration is an unusual rumbling or

grinding noise from the gear drive

at a narrow speed range. The noise

will decrease to normal levels when

the speed is increased or decreased

away from the offending speed

range. This noise is not indicative

of a defect, but results when the

vibratory torque exceeds the drive

torque, causing the gear teeth to

separate and clash together very

rapidly. On variable frequency

applications, avoid operation near

this resonance speed by locking out

the resonance speed range.

Loading...

Loading...