WWW.BALTIMOREAIRCOIL.COM

12

See Note 10

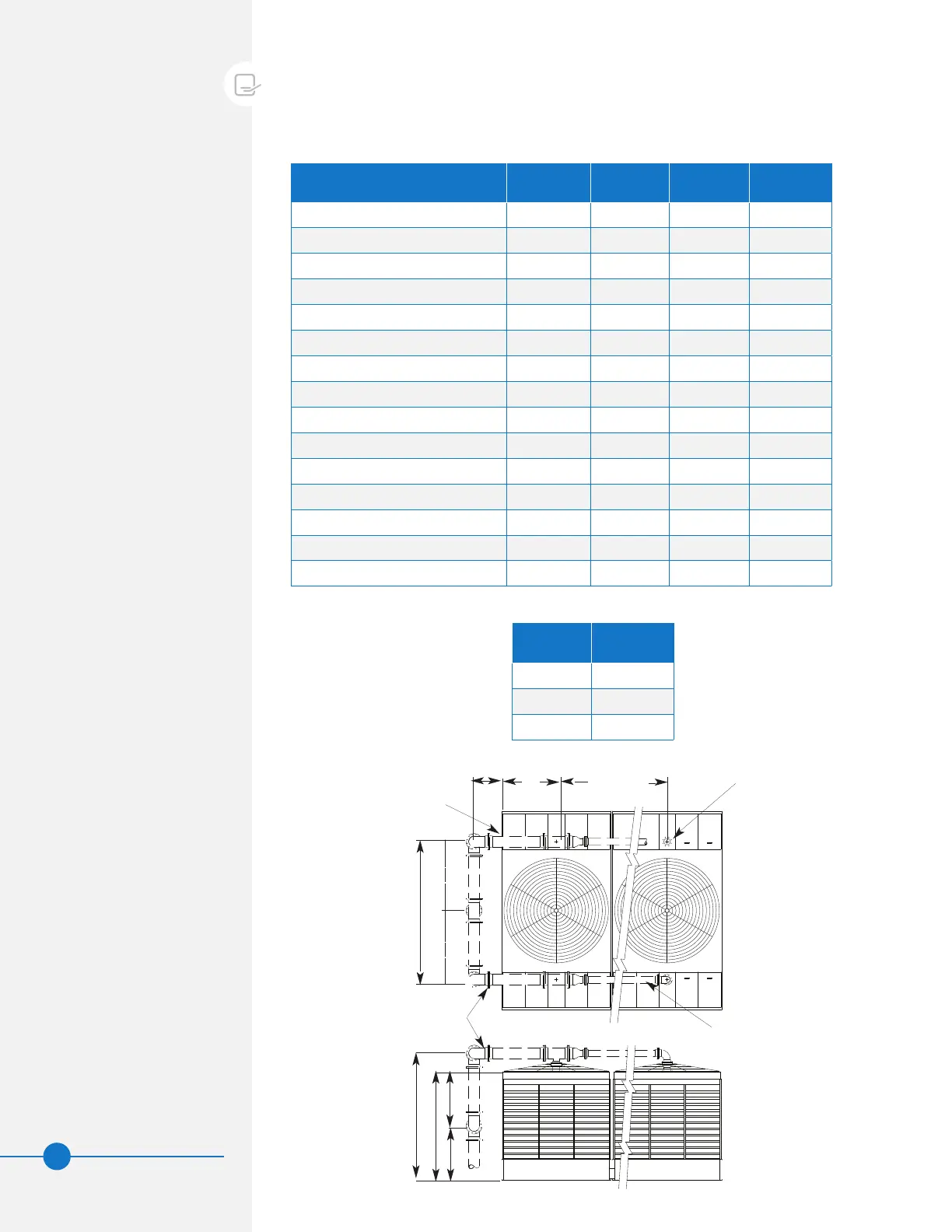

Pipe Support Location

See Figure 18, Detail A

C (Typ. Per

Cell)

Water Inlet

(See Unit Print For Size)

See Figure 18, Detail C

Pipe Support Location

See Figure 18, Detail A

See Note 5

Plan View

Elevation View

Static Lift

B

A

A A

22

H

H

HHH

2

2

Top Inlet Piping Installation

Use the following drawings, notes, and tables when installing top inlet piping.

Drawings shown are for multi-cell installations. For single cell installations, simply

ignore the additional cells and dimension “C” from Table 4.

Figure 16. Single Riser Piping Schematic

Table 4. Dimensions for Series 3000 Piping Schematic

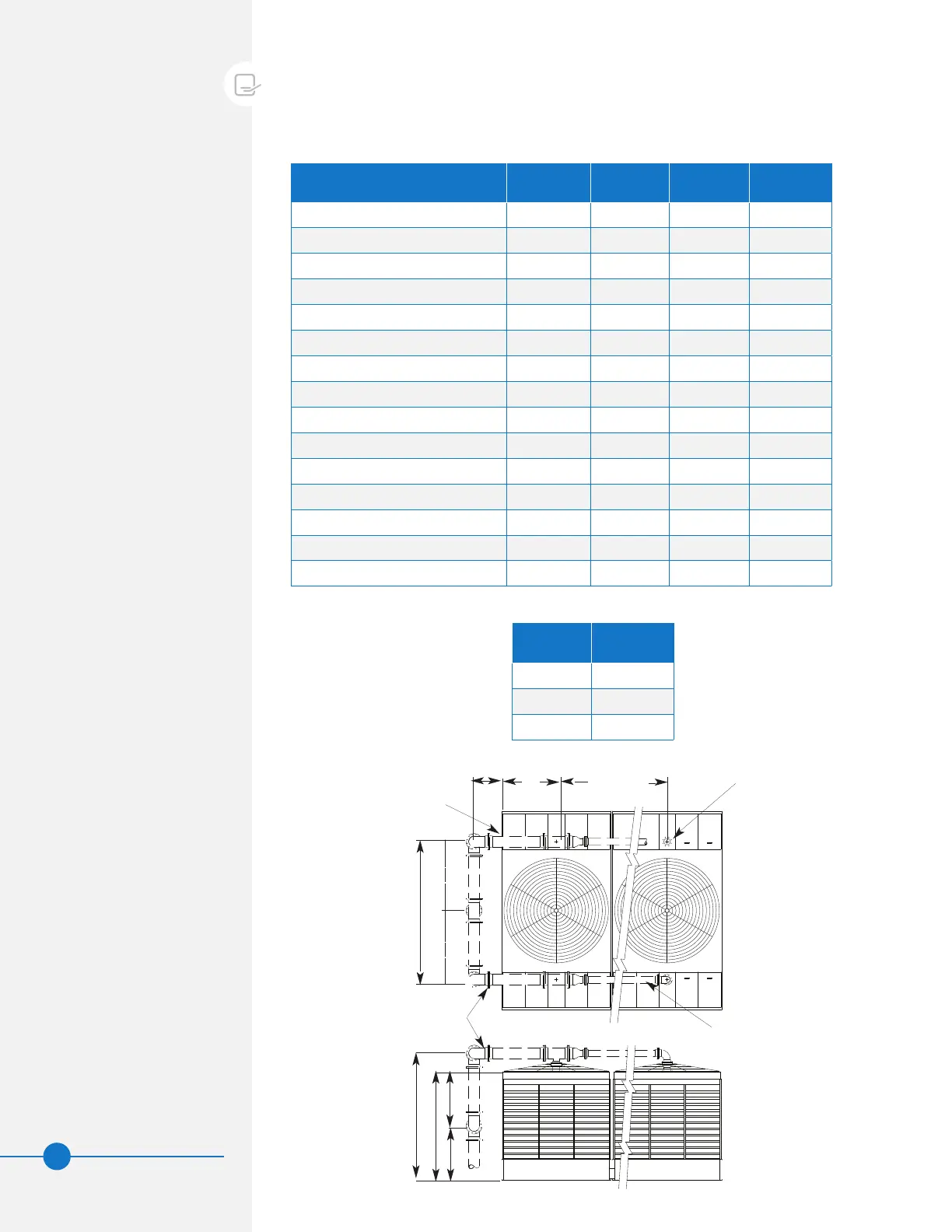

Model Number A B C H

S3E/XES3E-8518-05x 10’-6 3/4" 4’-2 7/8" 8’-8 1/4" 8’-7 3/4"

S3E/XES3E-8518-06x 10’-6 3/4" 4’-2 7/8" 8’-8 1/4" 9’-11 3/4"

S3E/XES3E-8518-07x 10’-6 3/4" 4’-2 7/8" 8’-8 1/4" 11'-3 3/4"

S3E/XES3E-1020-06x 12’-6 3/4" 4’-10 5/8" 9’-11 3/4" 9’-11 3/4"

S3E/XES3E-1020-07x 12’-6 3/4" 4’-10 5/8" 9’-11 3/4" 11’-3 3/4"

S3E/XES3E-1222-06x 14’-0 3/4" 5’-10 7/8" 12’-0 1/4" 9’-11 3/4"

S3E/XES3E-1222-07x 14’-0 3/4" 5’-10 7/8" 12’-0 1/4" 11’-3 3/4"

S3E/XES3E-1222-10x 14’-0 3/4" 5’-10 7/8" 12’-0 1/4" 15’-5 1/2"

S3E/XES3E-1222-12x 14’-0 3/4" 5’-10 7/8" 12’-0 1/4" 18’-1 1/2"

S3E/XES3E-1222-13x 14’-0 3/4" 5’-10 7/8" 12’-0 1/4" 19'-5 3/4"

S3E/XES3E-1222-14x 14’-0 3/4" 5’-10 7/8" 12’-0 1/4" 20’-9 1/2"

S3E/XES3E-1424-07x 16’-6 3/4" 6’-11 9/16" 14’-1 5/8" 11’-3 3/4"

S3E/XES3E-1424-12x 16’-6 3/4" 6’-11 9/16" 14’-1 5/8" 18’-1 1/2"

S3E/XES3E-1424-13x 16’-6 3/4" 6’-11 9/16" 14’-1 5/8" 19'-5 3/4"

S3E/XES3E-1424-14x 16’-6 3/4" 6’-11 9/16" 14’-1 5/8" 20’-9 1/2"

Table 5. Flow Control Valve

NOTES FOR FIGURE 16:

1. All piping shown by dashed

lines is to be furnished by

others. Refer to the certified

unit print for details on the

cooling tower.

2. Field piping should be

fabricated at the time of unit

installation. Pre-fabrication of

pipe work is not recommended.

3. Required static pumping head

from base of cooling tower

is indicated by static lift

dimension and piping friction

losses.

4. When tower is equipped with

safety railing package, inlet

piping should be designed to

clear the railing. Adjust static

lift as required.

5. For units installed on vibration

isolation rails (provided by

others), flexible connections

should be installed in the

piping just before the tower

perimeter.

6. All piping supports to be

designed, furnished, and

installed by others.

7. Supply piping to cooling

tower inlet connections may

be supported from the tower

structure only at the pipe

support locations shown. Piping

must not be supported by the

tower inlet connections. Piping

outside the perimeter of the

tower must not be supported

from the tower.

8. Supply piping supports must be

designed to rest on the walls

of the hot water distribution

basins at locations indicated

(see Figure 18, Detail A).

9. Maximum diameter of inlet

header piping that can be

supported by the cooling tower

distribution basins is 14”.

10. Provide adequate space

between cooling tower and riser

piping to allow for entry into the

cooling tower access doors.

Size Width

6” 2 1/4”

8” 2 1/2”

10” 2 13/16”

Loading...

Loading...