GENERAL INFORMATION

Pulsar 150/180 DTS-i

Service Station Manual

10

Dealer Development Center

Akurdi Pune

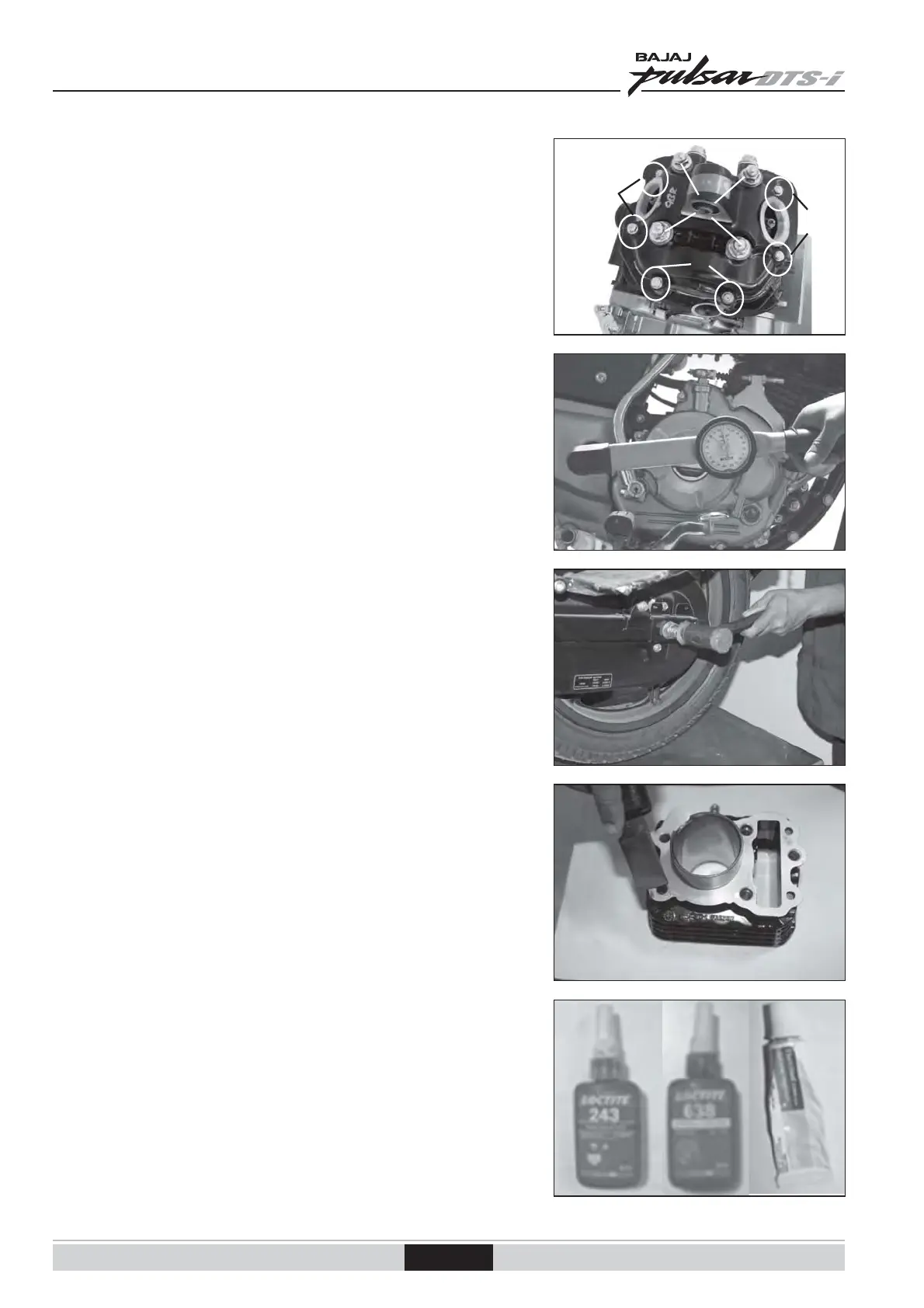

Tightening Sequence

Generally, when installing a part with several bolts, nuts, or screws,

start them all in their holes and tighten them to a snug fit. Then tighten

them according to the specified sequence to prevent case warpage or

deformation which can lead to malfunction. Conversely when loosening

the bolts, nuts or screws, first loosen all of them by about a quarter turn

and then remove them.

Tightening Torque

Incorrect torque applied to a bolt, nut, or screw may lead to serious

damage. Tighten fasteners to the specified torque using a good quality

torque wrench.

Force

Use common sense during disassembly and assembly, excessive force

can cause expensive or hard to repair damage. When necessary, remove

screws that have a non-permanent locking agent applied using an impact

driver. Use a plastic-faced mallet whenever tapping is necessary.

Gasket, O-ring

Hardening, shrinkage, or damage of both gaskets and O-rings after

disassembly can reduce sealing performance. Remove old gaskets and

clean the sealing surfaces throughly so that no gasket material or other

material remains. Install the new gaskets and replace the used O-rings

when re-assembling.

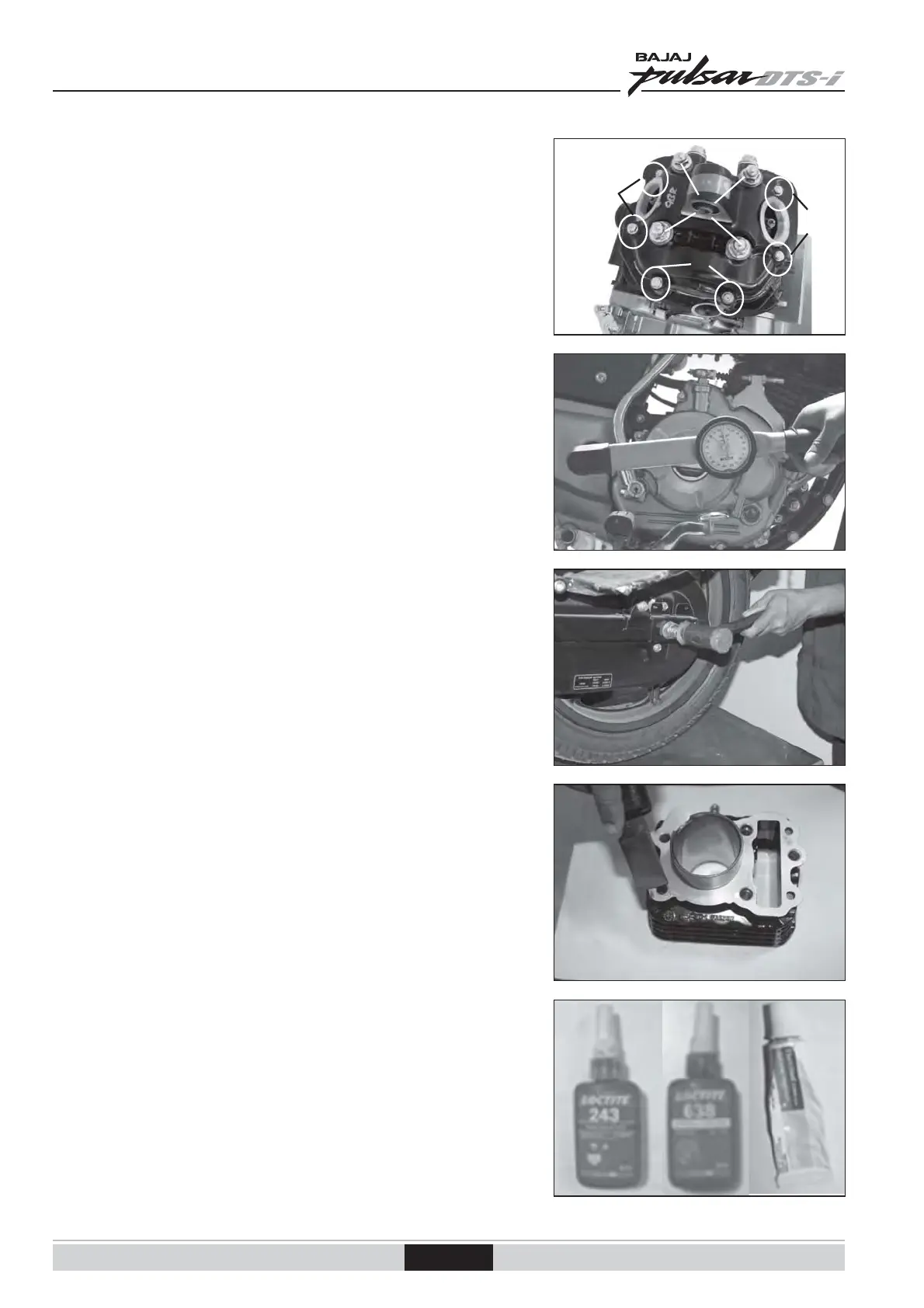

Liquid Gasket, Non-permanent Locking Agent

For applications that require liquid gasket or a non-permanent locking

agent, clean the surfaces so that so oil residue remains before applying

liquid gasket or non-permanent locking agent. Do not apply them

excessively. Excessive application can clog oil passages and cause

serious damage.

2

3

Tightening

Sequence

2

1

Loading...

Loading...