261/21

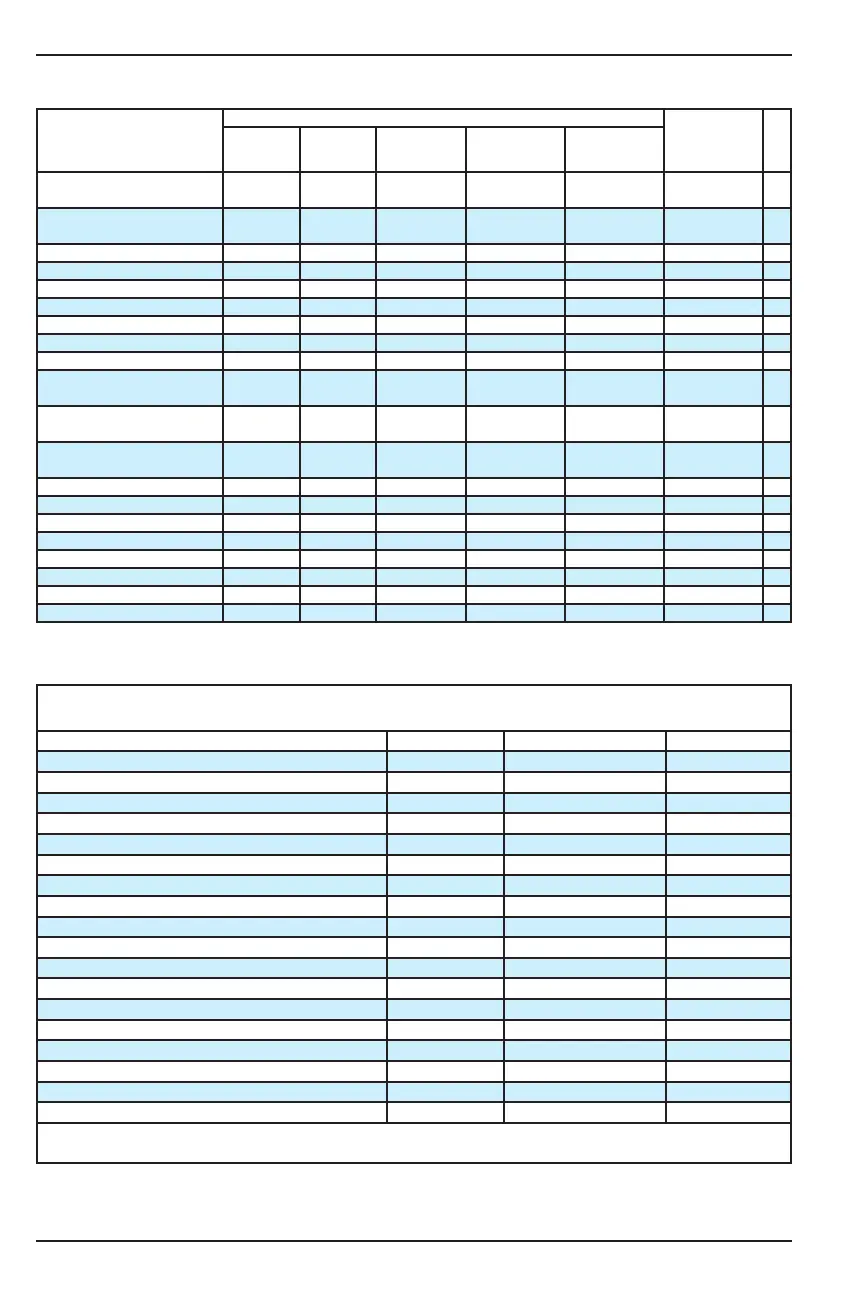

MODEL 200 UC MAINTENANCE

REMEMBER TO CHECK EVERYTHING ON THE CHECKLIST!

MAINTENANCE

What to Check

How often to check

Procedure

Page #

ü

Daily

(10 hrs.)

Weekly

(50 hrs.)

Monthly

(200 hrs.)

Quarterly

(500 hrs.)

Yearly

(2000 hrs.)

Safety procedures

reviewed

X 28

Anvil clearance,

tightness & wear

X 36 - 37

Alternator & fan belts X 29

Wheel lug nuts X 29

Steel friction areas X 29

Chain driven components X 29

Towing hitch X 29

Infeed wear X 29

Discharge wear X 29

Feedwheel motor

connections

X 44

Sharpness of feedwheel

teeth

X 29

Chipper sheave &

bearings

X 29

Hydraulic function pressure X 29

Wheel bearings X 29

Brakes X 29

Hydraulic oil lter(s) X 29

Discharge swivel plates X 29

Hydraulic oil X 29

Hydraulic suction screen(s) X 29

Fuel tank X 29

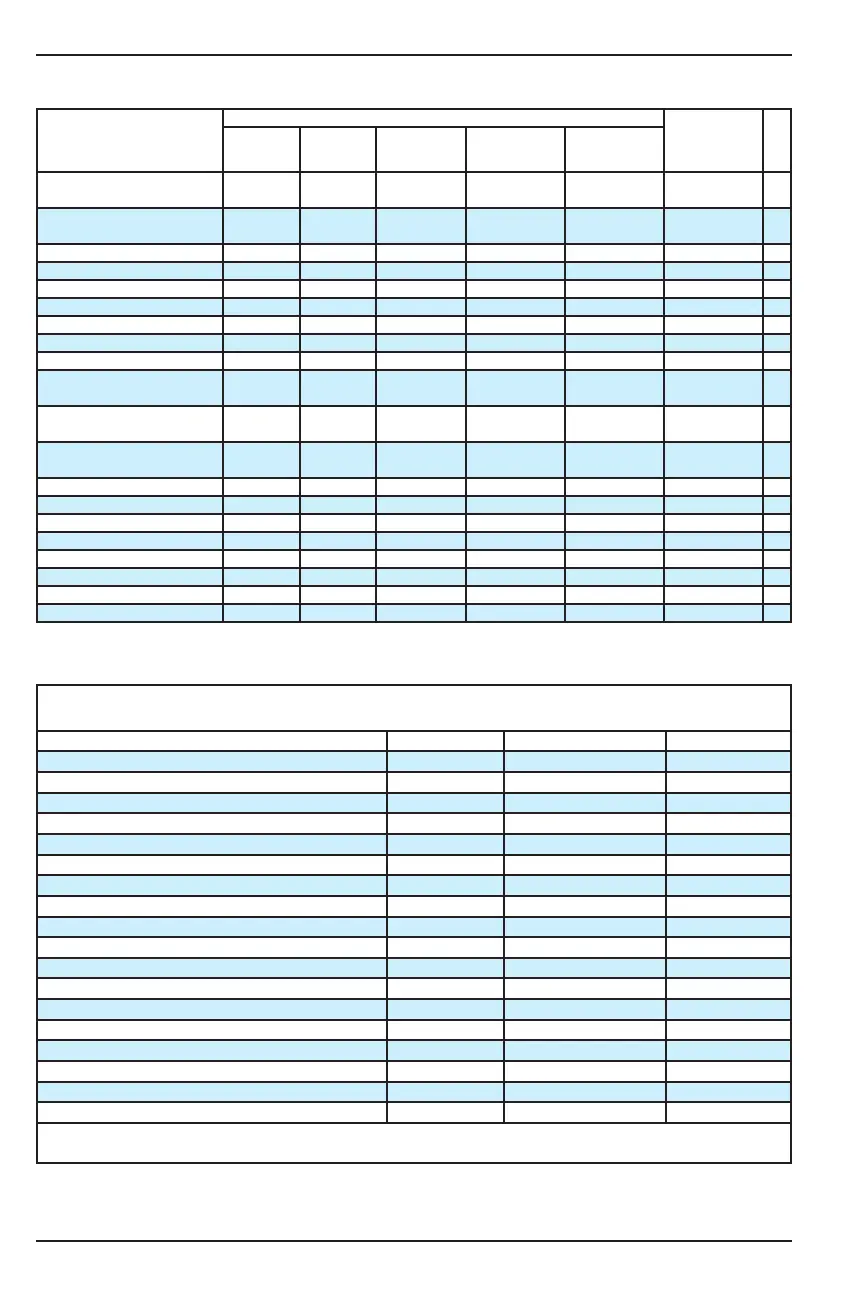

BOLT TORQUE CHART

(THESE TORQUES ARE BASED ON DRY, CLEAN THREADS)

DESCRIPTION BOLT SIZE TORQUE (FT.-LBS.) TORQUE (Nm)

Chipper Bearing Bolts 5/8” - 11 NC 150 203

Chipper Shaft Bearing Retainer 3/4” - 10 NC 170 230

Chipper Draw Ring 5/8” - 11 NC 150 203

Anvil 1/2” - 13 NC 65 - 75 88 - 102

Knife Bolts 1/2” - 13 NC 70 - 80 95 - 108

Feedwheel Bearing Bolts 1/2” - 13 NC 75 102

Feedwheel Bearing Set Screws 3/8” - 24 NF 20 27

Grip-Tight Feedwheel Bearing Set Screws 2 3

Engine Hold Downs 1/2” - 13 NC 60 81

“RS/TE” Hydraulic Feedwheel Motor Shaft Nut 3/4” - 28 NEF 150 - 170 203 - 230

Engine Sheave Bushing “SD” 1/4” - 20 NC 9 12

Engine Sheave Bushing “SK” 5/16” - 18 NC 15 20

Engine Sheave Bushing “2517” 1/2” - 13 NC 60 81

Engine / Chipper Sheave Bushing “SF” 3/8” - 16 NC 30 41

Pump Sheave Bushing “H” 1/2” - 13 NC 60 81

Autofeed Cartridge Nut 4 - 6 5 - 8

Autofeed Plus Solenoid Retainer Nut 4 - 6 5 - 8

Hitch Mount Bolts 5/8” - 11 NC 220 298

Before tightening bolts be sure you have the correct size bolt for the correct amount of torque.

Use only factory approved knives and hardware.

Loading...

Loading...