Step 8: Determine the required allowance for pumps, valves, flanges and pipe supports:

Determine the required allowances for pumps, valves, flanges and pipe supports using the following table:

→ Example

Pipe diameter: DN25

1 pump

2 valves

6 flanges

24 pipe supports

The total required allowance is calculated as follows:

total required allowance = no. of pumps × pump allowance value +

no. of valves × valve allowance value +

no. of flanges × flange allowance value +

no. of pipe supports × pipe support allowance value

= 1 × 2.1 m + 2 × 0.6 m + 6 × 0.3 m + 24 × 0.3 m

= 12.3 m

Step 9: Add all lengths / allowances together:

Add the lengths for piping (as determined in step 6) and allowances (as determined in step 7 and step 8) together to obtain total required trace

heater length.

→ Example

required trace heater length for piping (step 6): 50 m

required allowances for connection kits (step 7): 1.0 m

required allowances for pumps, valves, flanges and pipe supports (step 8): 12.3 m

total required trace heater length = required trace heater length for piping + required allowances

= 50 m + 1.0 m + 12.3 m

= 63.3 m

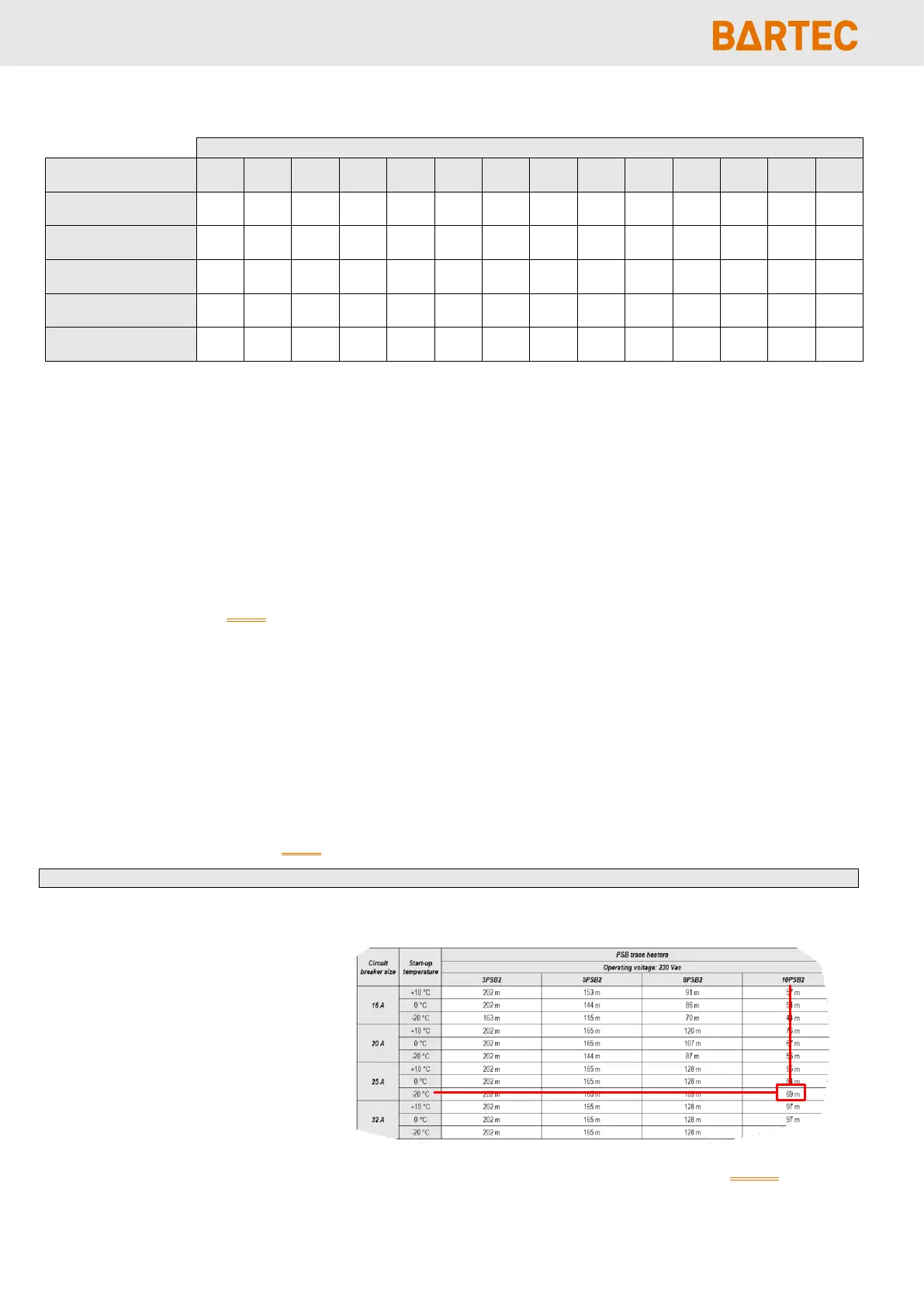

Determination of the required number of heating circuits

Step 10: Confirm the number of electrical circuits required for the application:

Using Table G on page 18, compare the required heater length and start up temperature to the available circuit breaker allowances to determine

the number of electrical circuits that will be required.

→ Example

total required trace heater length: 63.3 m

circuit breaker voltage: 230 Vac

selected trace heater: 10 PSB

circuit breaker amperage: 25 A

required start-up temperature: -20 °C

allowable trace heater length from table below = maximum of 69 m at -20 °C on 25 A circuit breaker at 230 Vac

= 63.3 m calculated < 69 m maximum allowable for 25 A = 1 circuit

Loading...

Loading...