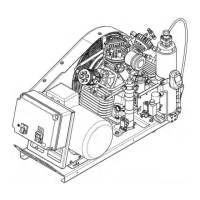

What to do if my Bauer POSEIDON PE 200-TE's control system does not switch off?

- Sstephanie57Sep 10, 2025

If the control system of your Bauer Air Compressor does not switch off and the final pressure safety valve blows, it could be because the final pressure monitor is set too high or the final pressure safety valve is defective. Rectify the setting and replace the safety valve.