35

INSTALLER Section (en)

7651556.01 (1-01/16)

12.4 COMBUSTION TEST (CO

2

%)

For correct boiler operation, the content of (CO

2

- O

2

) in the combustion fumes must observe the tolerances indicated in the

IROORZLQJWDEOH,IWKHYDOXHRI&2

2

- O

2

) is different, check the electrodes and their relative distances. If necessary, replace the

HOHFWURGHVDQGSRVLWLRQWKHPFRUUHFWO\,IWKHSUREOHPSHUVLVWVXVHWKHIROORZLQJIXQFWLRQ

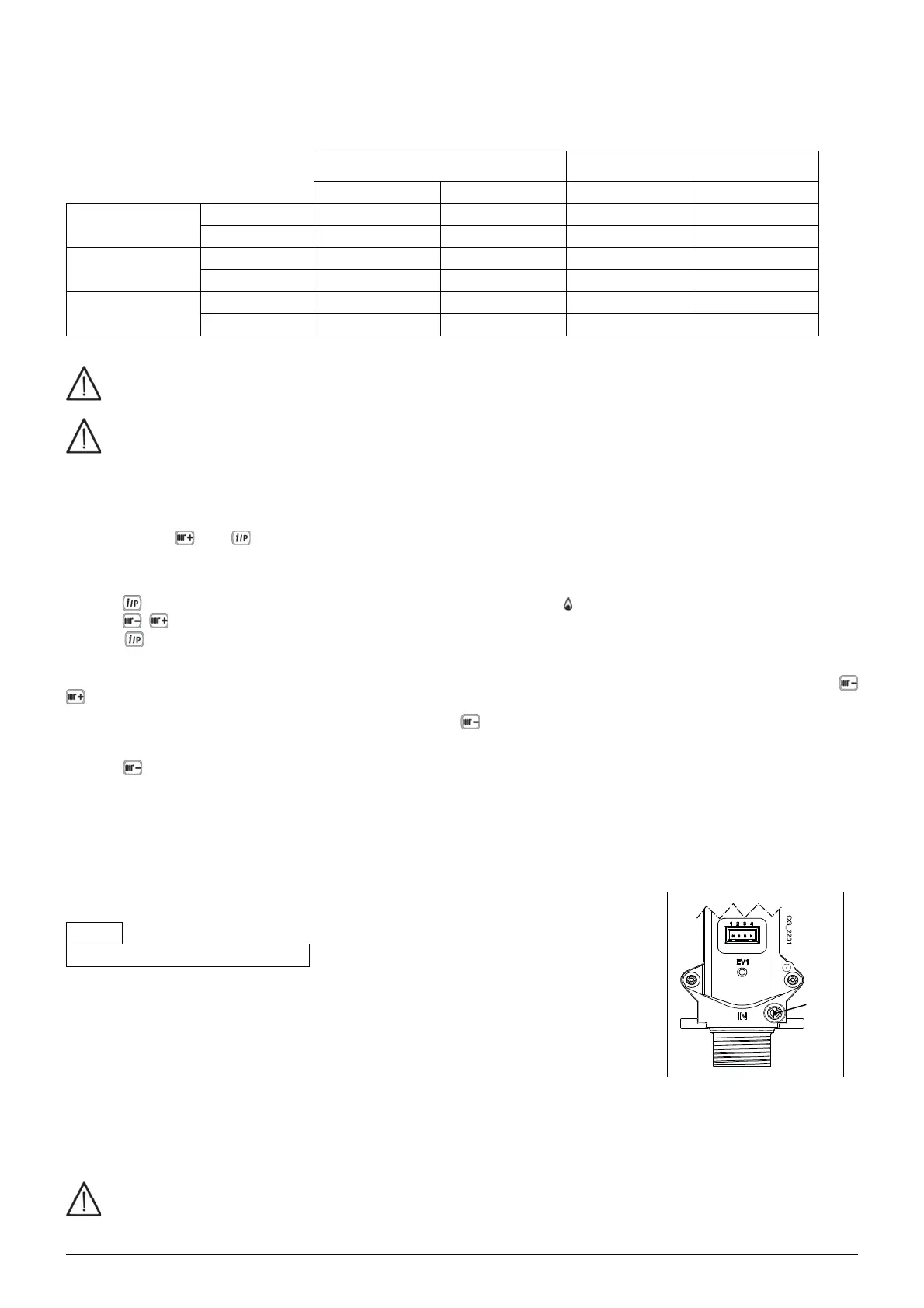

G20 G31

CO

2

%O

2

%CO

2

%O

2

%

0D[LPXPSRZHU

Nominal value 8.7 5.4 10.0 6.0

Permitted value 8.2 - 9.3 6.3 - 4.3 9.5 - 10.5 6.8 - 5.2

,JQLWLRQSRZHU

Nominal value 8.7 5.4 10.8 4.8

Permitted value 8.2 - 9.3 6.3 - 4.3 10.3 - 11.3 5.5 - 4.1

0LQLPXPSRZHU

Nominal value 8.8 5.2 10.0 6.0

Permitted value 8.2 - 9.3 6.3 - 4.3 9.5 - 10.5 6.8 - 5.2

7KHFRPEXVWLRQVDQDOLV\VVKDOOEHGRQHXVLQJDQDQDO\]HUUHJXODUO\FDOLEUDWHG

'XULQJQRUPDORSHUDWLRQWKHERLOHUSHUIRUPVFRPEXVWLRQFRQWUROF\FOHV,QWKLVSKDVH&2YDOXHVKLJKHUWKDQSSPFDQ

occur for brief periods of time.

COMBUSTION ADJUSTMENT FUNCTION (CO

2

%)

This function sets out to partially adjust the value of CO

2

%7KHIROORZLQJSURFHGXUHLVXVHG

• Press buttons and WRJHWKHUIRUDWOHDVWVHFRQGV:KHQWKHIXQFWLRQLVHQDEOHGWKHGLVSOD\VVKRZV³On´IRUDIHZ

VHFRQGVIROORZHGE\SURJUDPPHURZ³304´DOWHUQDWHGZLWKWKH%RIERLOHUSRZHU

• $IWHUWKHEXUQHULVOLWWKHERLOHUUHYHUWVWRPD[LPXP'+:SRZHU:KHQWKHGLVSOD\VKRZV100LWLVSRVVLEOHWRSDUWLDOO\

adjust the value of CO

2

%

• press

7KHGLVSOD\VKRZV00DOWHUQDWLQJZLWKWKHIXQFWLRQQXPEHU304 ÀDVKHV

• press

WRUDLVHRUORZHUWKHDPRXQWRICO

2

(from -3 to +3).

• press

WR VDYH WKH QHZ YDOXH DQG YLHZ WKH SRZHU YDOXH RQ WKH GLVSOD\ DJDLQ WKH ERLOHU FRQWLQXHV RSHUDWLQJ DW

PD[LPXP'+:SRZHU

This procedure can also be used to adjust the quantity of CO

2

to the LJQLWLRQSRZHU and to the PLQLPXPSRZHU by pressing

after point 5 of the procedure described above.

• $IWHUVDYLQJWKHQHZYDOXHSRLQWRIWKHSURFHGXUHSUHVV to take the boiler to its LJQLWLRQSRZHU. Wait for the value of

CO

2

WRVWDELOLVHDQGWKHQDGMXVWDVGHVFULEHGLQSRLQWRIWKHSURFHGXUHWKHSRZHUYDOXHLVDQXPEHU!DQG!WKHQ

save (point 5).

• press

again to take the boiler to PLQLPXPSRZHU. Wait for the value of CO

2

to stabilise and then adjust as described in

SRLQWRIWKHSURFHGXUHSRZHUYDOXH

• to exit the function, press the buttons for at least 6 seconds as described in point 1.

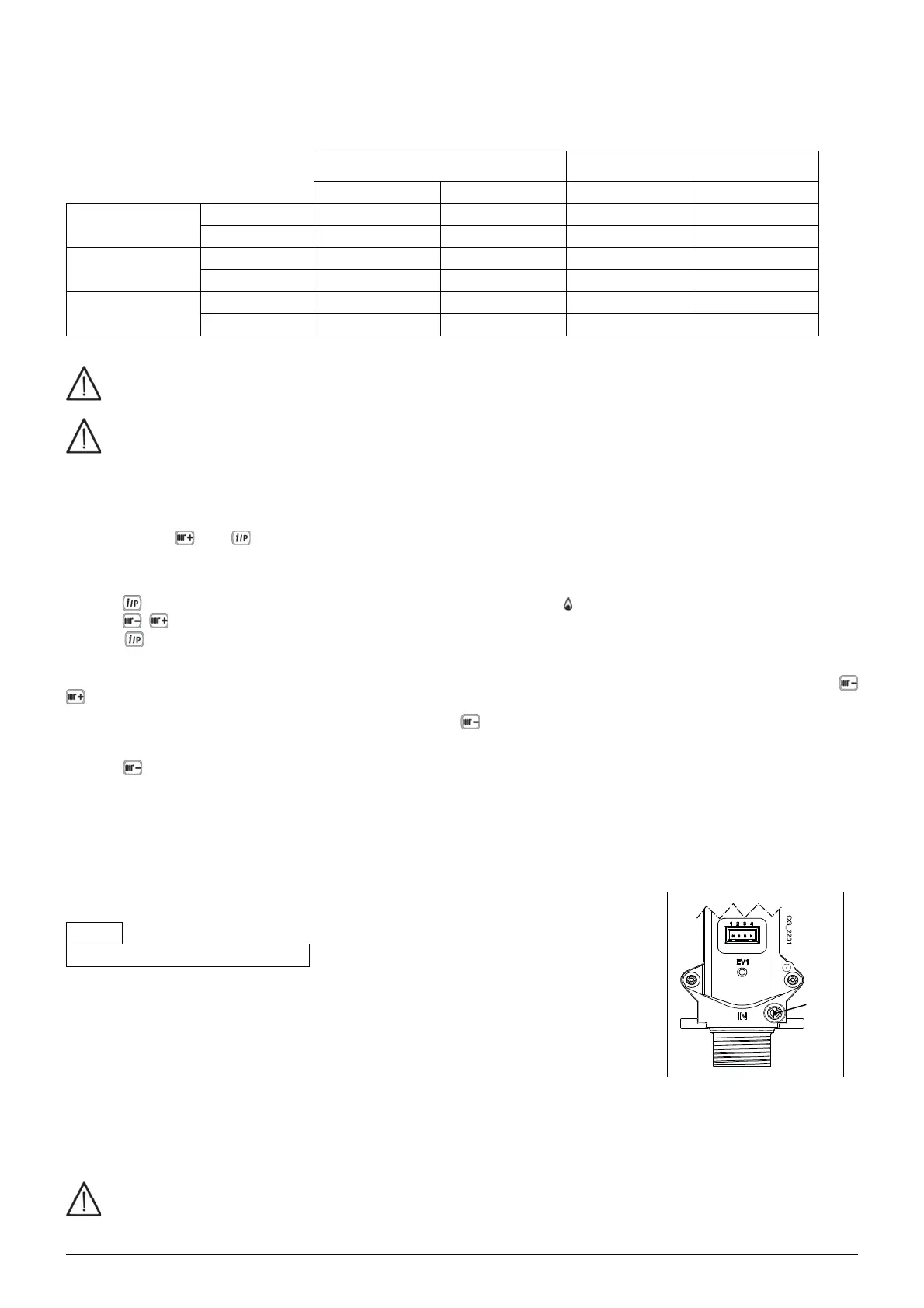

13. GAS VALVE

This appliance does not require any mechanical adjustment on the valve. The system ensures electronic auto-adaptation.

*DVYDOYHNH\

Pi

Gas supply inlet pressure tap

13.1 GAS CONVERSION METHODS

Only an Authorised Technical Assistance Service can convert boiler operation from NATURAL GAS to LPG or vice-versa. To

perform calibration, set parameter P02 as described in the PARAMETER SETTINGS section. Lastly, check the combustion

parameters as described in the SPECIAL FUNCTIONS - CHECKING COMBUSTION PARAMETERS section.

:KHQWKHJDVFKDQJHLVFRPSOHWHGWKHERLOHUGDWDSODWHPXVWEHDPHQGHGWRLQGLFDWHWKHQHZJDVGDWD

Pi

Loading...

Loading...