If the new values are not to be stored, exit the menu by pressing the ALARM RESET key (F). The old

values which were active before the menu was opened will then remain in operation.

3.5.2 Alarm connection

External alarm with own electricity supply (max. 24 V - 3 Amp) can be connected to clamps 11 and 12

(see electrical diagram).

Page 20

3.6 Assembly guidelines

3.6.1 The pipe connections - choice of materials

For the central heating side, it is possible to use a mixed material consisting of copper - steel. The flow

and return pipe must be carefully insulated in order to avoid heat loss.

3.6.2 Back-burn safety valve

Must be connected to the domestic water supply and a pressure tank for flood water storage. In the piping

run between the flood water storage tank and the burn back safety valve, there must NOT any valve(s)

installed which could be inadvertently closed or shut off.

On the one side panel, there is a cut-out for the pipe assembly - this can be moved or exchanged to the

side where the assembly is needed.

3.6.3 Frost protection

The central heating system can be protected against frost by means of an anti-freeze mixture.

3.6.4 Boiler and return temperature

As noted in section 1.3 we recommend keeping the boiler temperature at 80°C.

The return temperature must be at least 60°C to minimise the risk of corrosion in the boiler.

The by-pass valve in the drawing, point 3.7 must be fitted and adjusted in order to ensure this return

temperature.

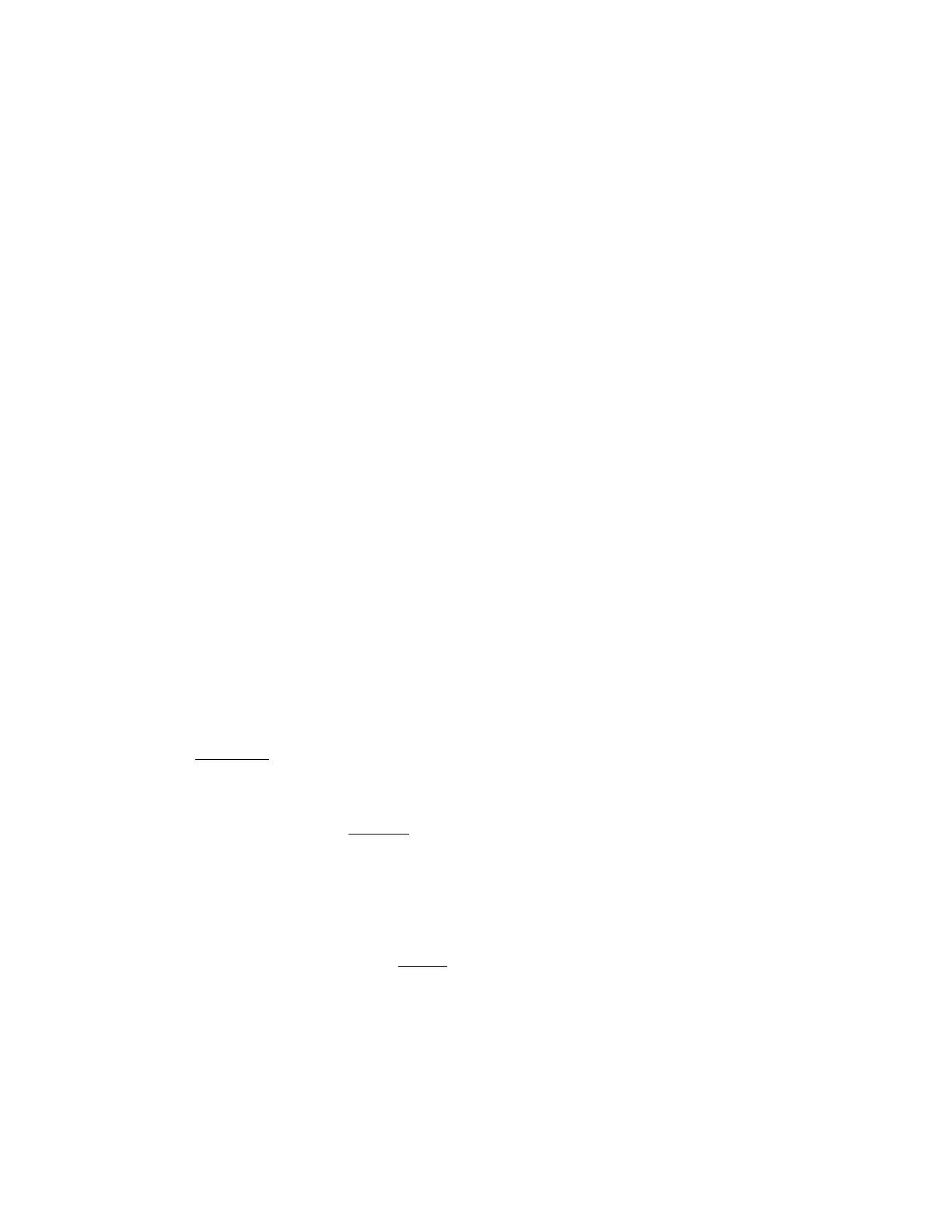

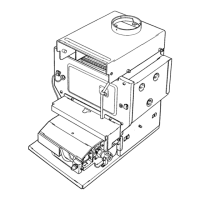

3.6.5 Arrangement

The boiler must be set up on a stable foundation.

The boiler must be mounted as shown on fig. 3.7.

It is important to ensure that the worm-conveyor can be removed during service.

Type 1,5 If there is insufficient space for this, the worm conveyor/auger can be taken up through the

hopper, by first leading the worm conveyor/auger 160 mm further back than the gear motor, and then

subsequently leading the worm conveyor/auger up through the hopper.

Loading...

Loading...