The version for firing with wood chips (model F) has a hopper in the stirrer or agitator system which

transports the fuel to the worm conveyor/auger. We recommend a chip size of 5-30 mm with a water/

moisture content of 25% or less.

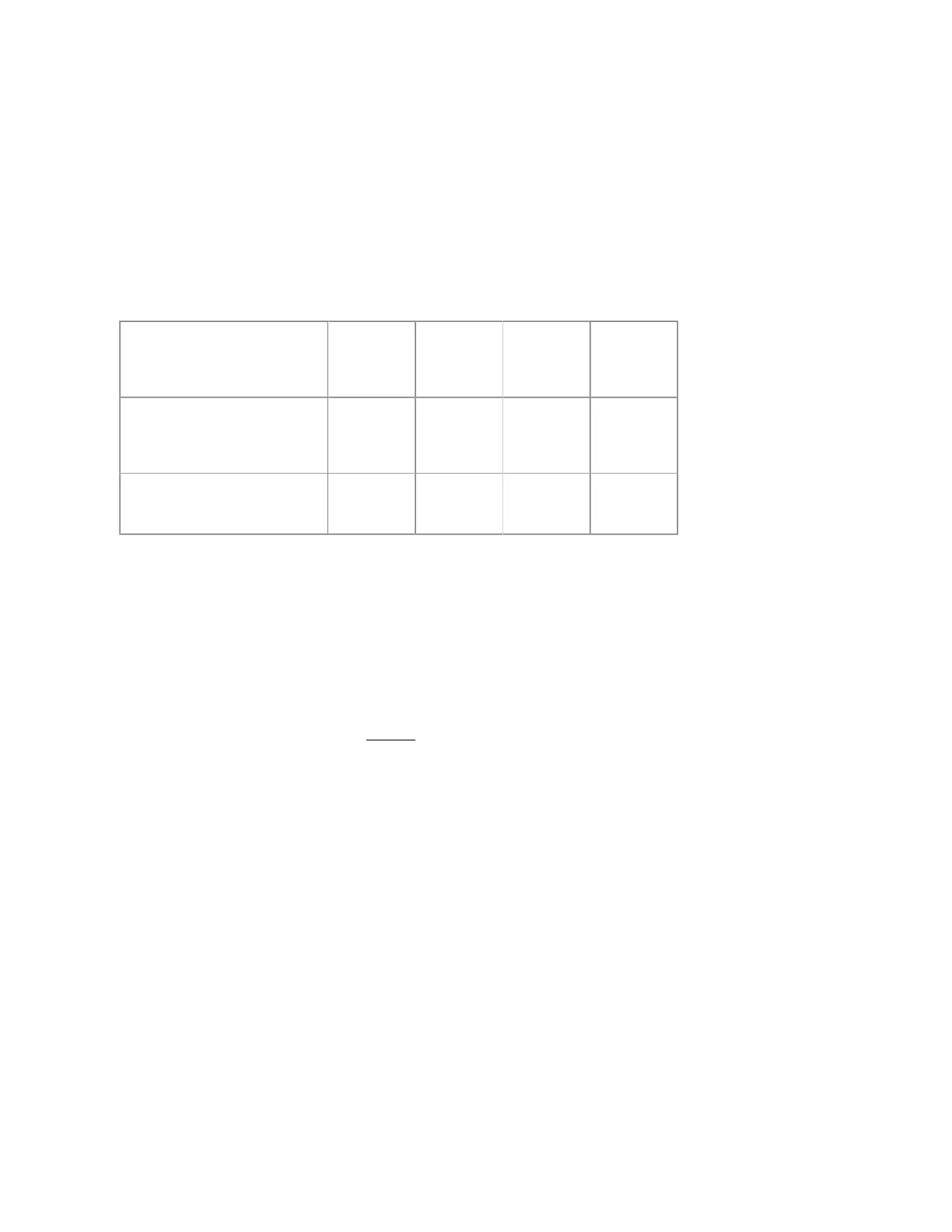

Change-over

When changing fuel-type it is important to switch over the boiler corresponding to the correct equipment

and the new operation setting.

Use of equipment

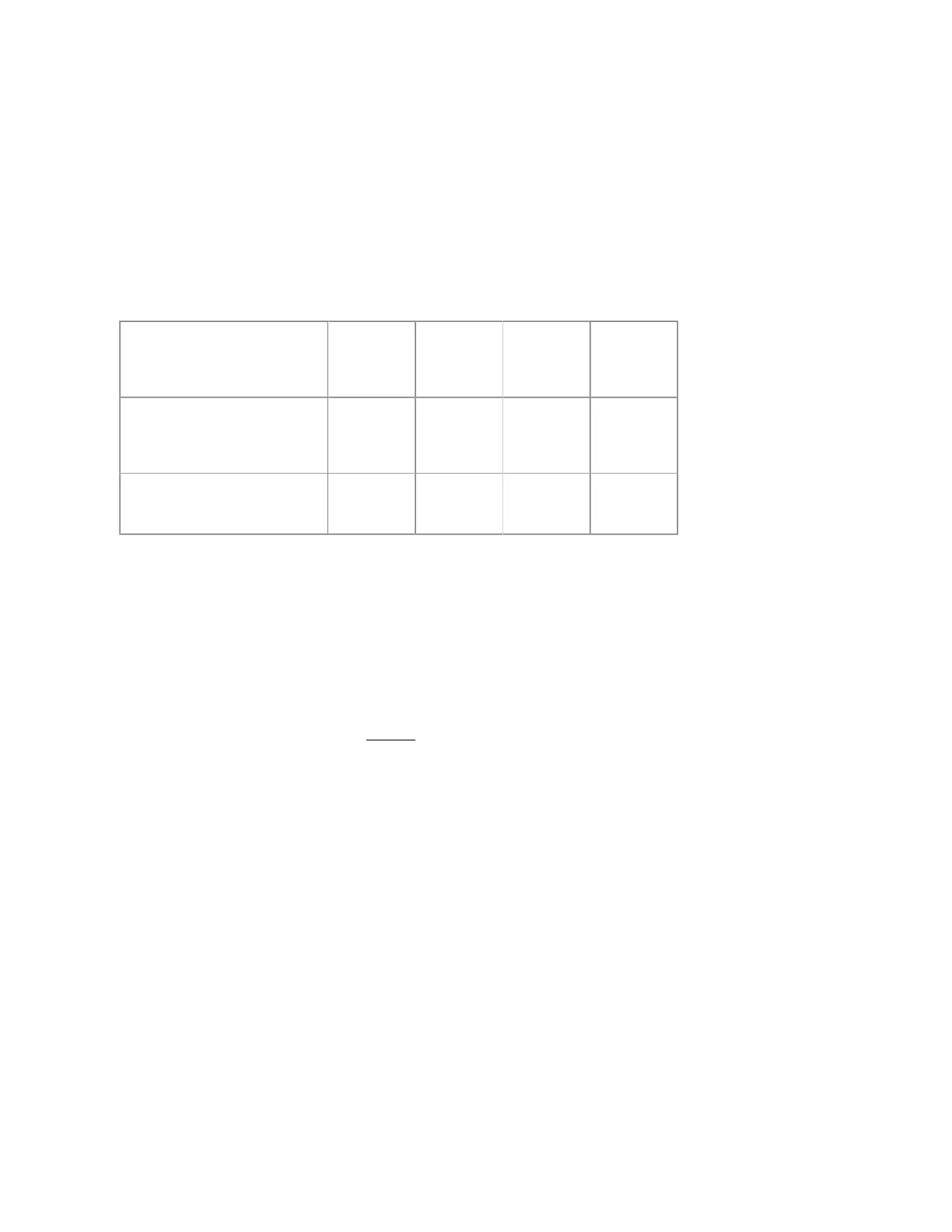

Wood

pellets

Grain

Corn

(Maize)

Wood

chips

worm conveyor/auger

extension

÷ + + ÷

Stirrer / agitator ÷ ÷ ÷ +

+ = must be used

÷ = must not be used

Usage of other and less suitable fuel types for MULTI-HEAT - over and above the wood pellets indicated

above, grain (wheat and barley), corn (maize) as well as wood chips can result in less problem-free

operation, more work for the user and possibly a greater fuel consumption. Consult the factory for advice

with regard to the possibilities of using other types of fuel.

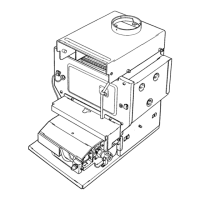

1.1.2 Function (Refer if necessary to fig. 1.1)

The fuel worm conveyor/auger (11) "screws" the fuel into the boiler's combustion chamber (4).

The combustion air is supplied via the built-in blower (13) down through holes (7) at the back and up into

the fuel.

The flue gas passes upwards through the boiler's combustion chamber (3) and via a well-dimensioned

number of horizontal fire tubes with stirrers or turbo-mixers, the flue gas is returned to the return/cleaning

chamber (16) and leaves the boiler via the vertical smoke nozzle (18).

Page 4

Safety: Insofar as the fire moves backwards into the fuel supply pipe, the retrograde combustion (back

burn) safety device (12) will extinguish the fire with water.

If the fire goes out, a built-in smoke gas sensor will turn off the boiler and sound an alarm. The boiler

must not run with the doors to the hopper door (17) open.

Loading...

Loading...