page 4

© Baxi Heating UK Ltd 2011

CONCENTRIC FLUE SYSTEM (60/100) ONLY - FLUE GROUP A

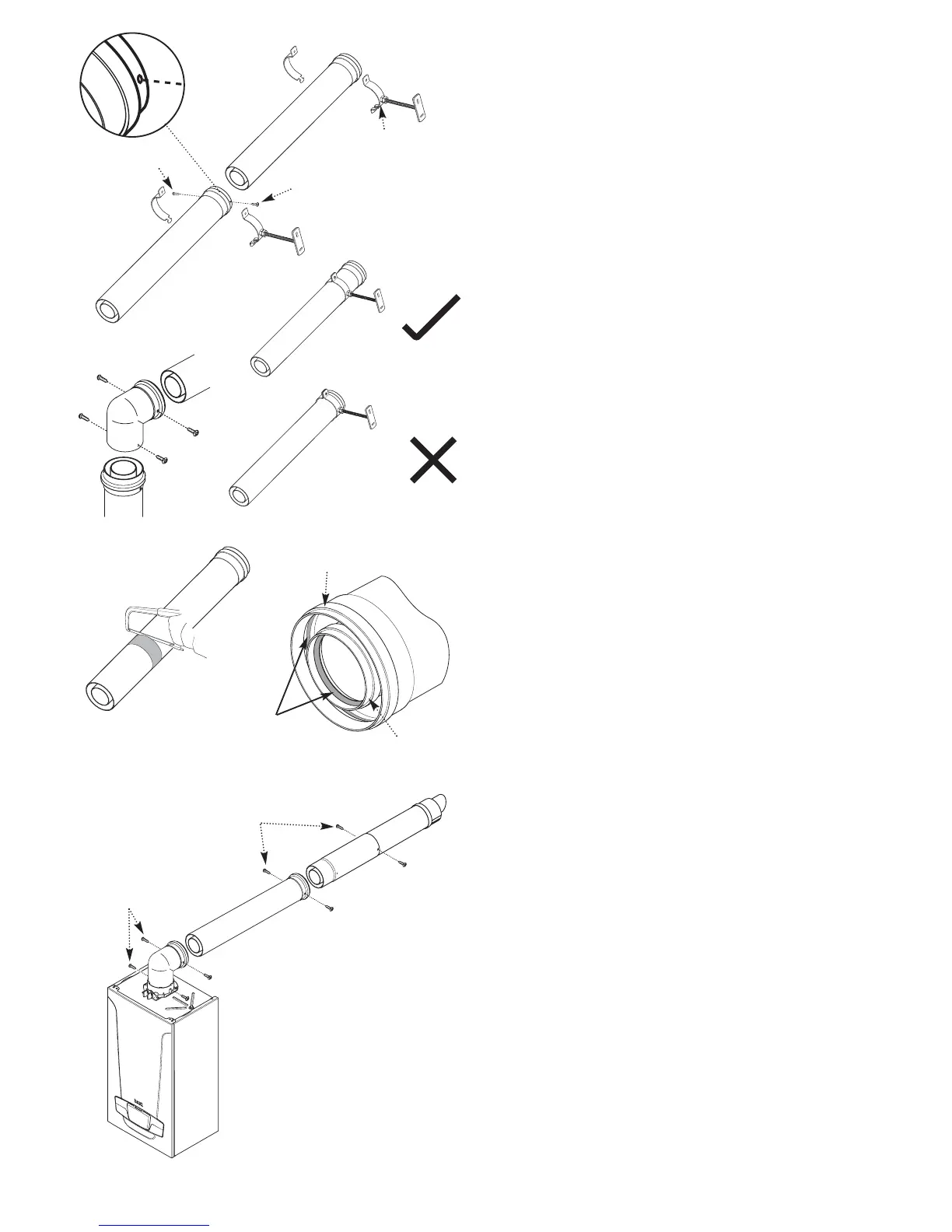

USE OF SUPPORTS & SECURING

Each extension and securing screws (1m, 500mm & 250mm) is

supplied with a support bracket. Additional support brackets can be

purchased separately (see Flue Accessory page overleaf). DO NOT

use brackets other than those supplied or shown in this guide.

The flue system MUST be supported AT LEAST once every metre

of actual length, and every straight length should be supported with

a bracket.

The bracket should be positioned as close to the female end of the

extension providing that the surface the bracket is to be fixed to is

sound. DO NOT position the bracket over the swaged part of the

extension or the rivets.

Also provided with each extension and elbow are two special self

drilling screws. These MUST be used to secure the female air duct

to the male duct of the next extension or elbow (in exceptional

circumstances were access is limited one screw will suffice).

CUTTING EXTENSIONS

Where it is necessary to reduce the length of an extension, both

exhaust and air duct MUST be cut square and flush, and any burrs

removed to avoid damage to the flue seal on both exhaust and air

duct on assembly.

It is recommended that tape is used as a guide to first cut around

the air duct and then the exhaust duct be cut square and flush with

the air duct.

The spring support should be positioned approximately 100mm

from the male end of the extension to maintain concentricity.

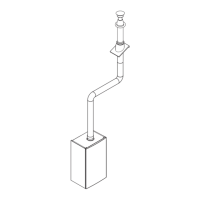

ASSEMBLING

Both ducts of the elbow or extension are fitted with an inner lip

seal. It is important that the seals are lubricated as follows:-

Use suitable gloves - open the sachet of grease supplied and apply

grease sparingly to the inner seal of both air and exhaust ducts to

aid assembly.

Wipe away any excess grease prior to assembly. Avoid contact with

eyes after handling the grease, and thoroughly wash hands.

Engage the male end of the extension or elbow into the female of

the next extension or elbow. Ensure that it is fully inserted to

achieve the required penetration depth. The extension have been

designed to maintain an expansion gap for the exhaust duct.

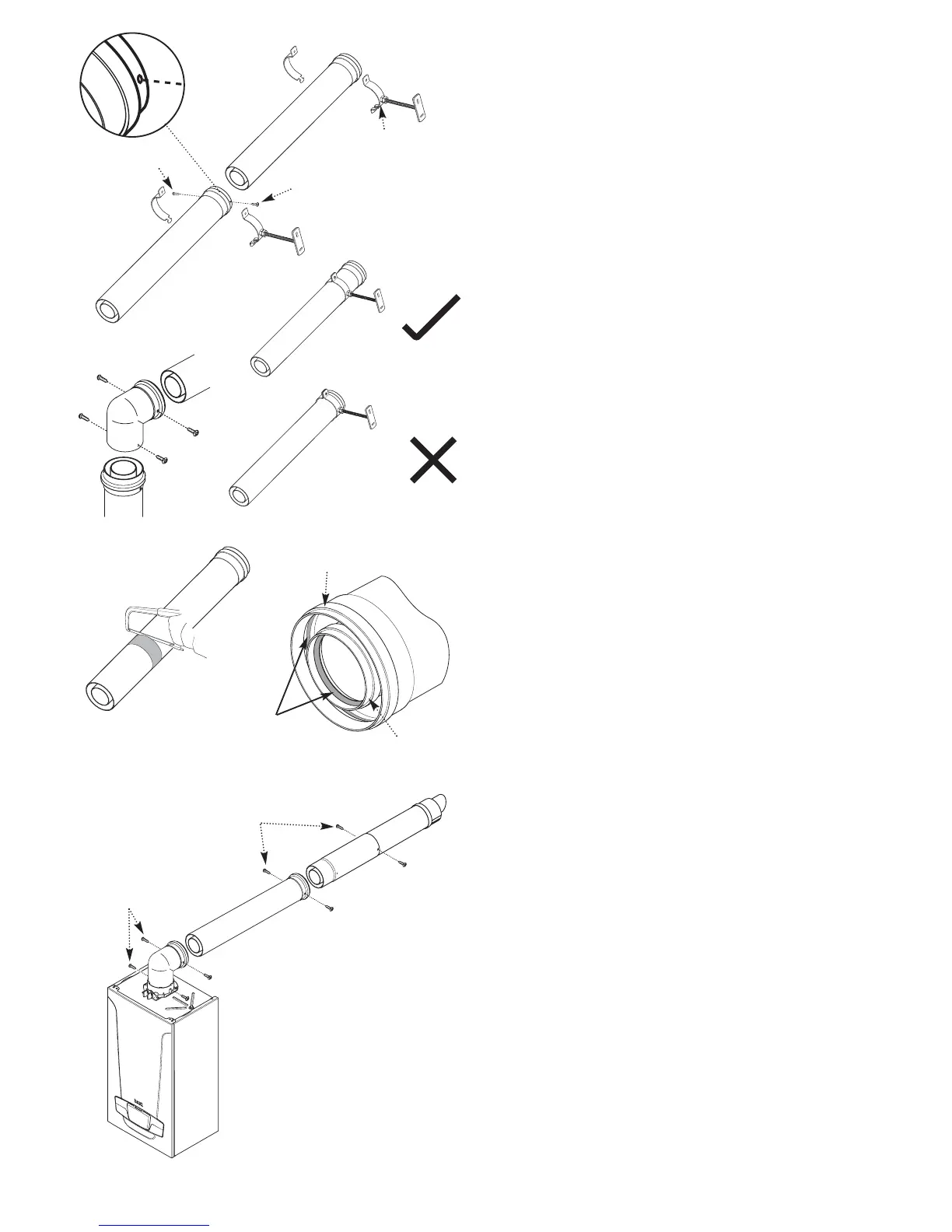

Using the special self drilling screws supplied secure the air duct to

the next extension or elbow. The screws must be inserted via the

holes in the female end of the air duct or through the indentations

on elbows/bends. NOTE: No drilling is required - the screw will

pierce the male end of the extension or elbow.

Identify the positions of the support brackets and mark the wall or

surface on which they will be mounted. Drill and plug as required.

If necessary shorten the threaded rod. Fix the support bracket to

the wall. Locate the tongue of the outer bracket half in the slot of

the inner half. When all brackets are in place offer the flue up to

them, and secure the two halves of the brackets with the screw. If

the rods are not long enough it may be necessary to erect a spacer

or structure to adequately support flue system brackets. It is not

recommended to use longer threaded rods.

IMPORTANT: Mounting and securing the flue will be easier if

performed by two people ! When the flue system is in place fully

tighten all brackets systematically, ensuring that no parts are under

any strain or tension and no dips where condensate can pool.

Silicone grease to

be applied to both

seals to aid fitting

Securing Screw

Securing Screw

Air Duct

Exhaust Duct

Securing Screws

Securing Screws

Support Bracket

Loading...

Loading...