360mm Min

(50/4 only)

125mm

xk

r

kt

ri').

;;;;

O

Viltgl

ks

For optimum operating conditions, the heating system

'into which the boiler is installed should include a

-

control system.

Such a system will comprise of timer control and a

'

,

separate room or cylinder thermostat as appropriate.

The boiler should be controlled so that it operates on

demand only.

Operation of the system under control of the boiler

thermostat only, does not produce the best results.

Where necessary a frost thermostat should be fitted to

protect the boiler and if necessary the system.

Reference should be made to the control equipment

manufacturer's literature for information e.g. wiring

•

diagrams, etc.

175mrn Min

(225mm Min

50/4 only)

For Minimum

Operating Head

See Pump

Manufacturers

Instructions

538mm Min

150mm Max

22mm Open Vent

(30-40/4 only)

28mm Open Vent

(50-70/4 only)

100mm Min

I

Return

Row '1 I

CD

C

to

0(t

Iv

Head Insta

%

lla

•

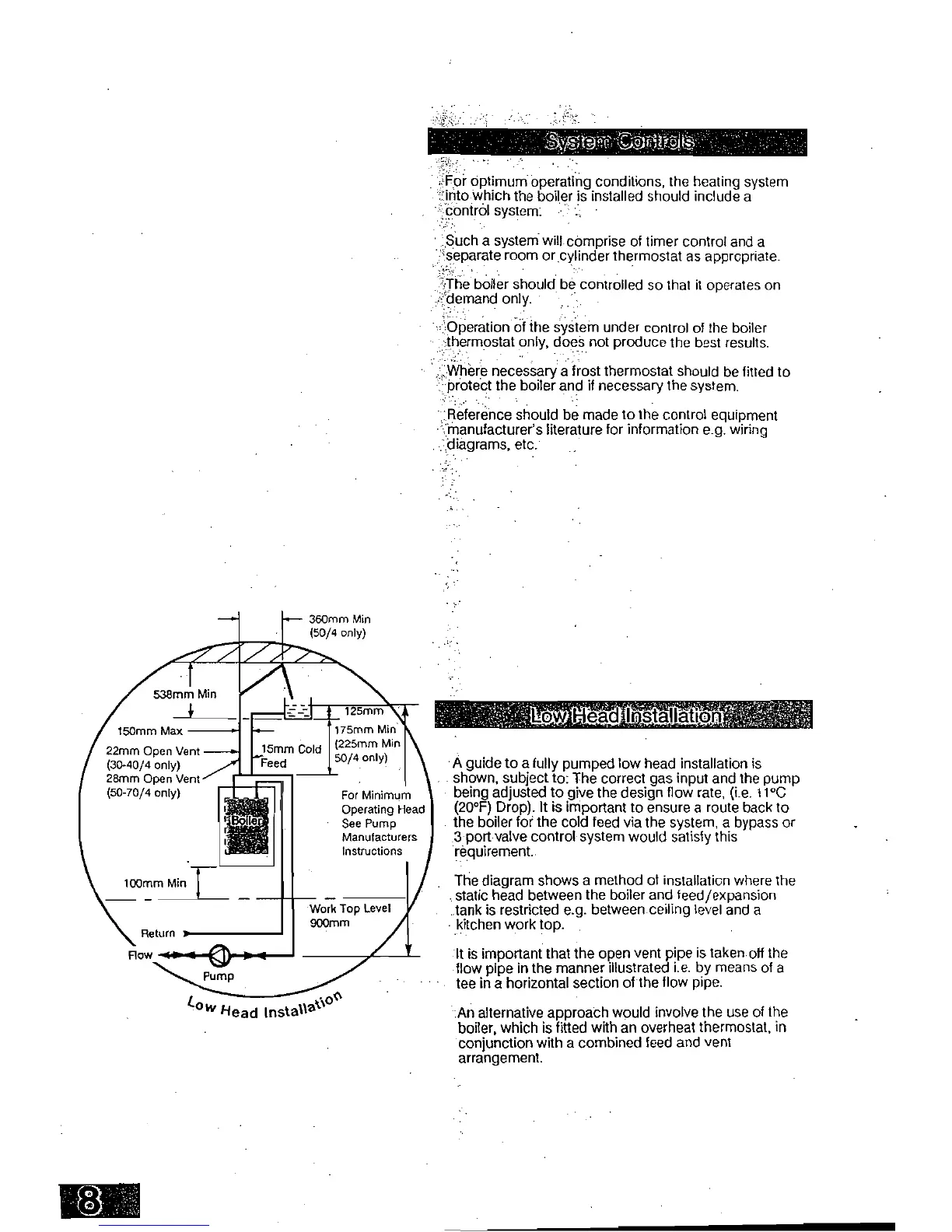

A guide to a fully pumped low head installation is

shown, subject to: The correct gas input and the pump

being adjusted to give the design flow rate, (i.e. 11°C

(20°F) Drop). It is important to ensure a route back to

the boiler for the cold feed via the system, a bypass or

3 port valve control system would satisfy this

requirement.

The diagram shows a method of installation where the

static head between the boiler and feed/expansion

tank is restricted e.g. between ceiling level and a

•

kitchen work top.

It is important that the open vent pipe is taken off the

flow pipe in the manner illustrated i.e. by means of a

tee in a horizontal section of the flow pipe.

An alternative approach would involve the use of the

boiler, which is fitted with an overheat thermostat, in

conjunction with a combined feed and vent

arrangement.

Loading...

Loading...