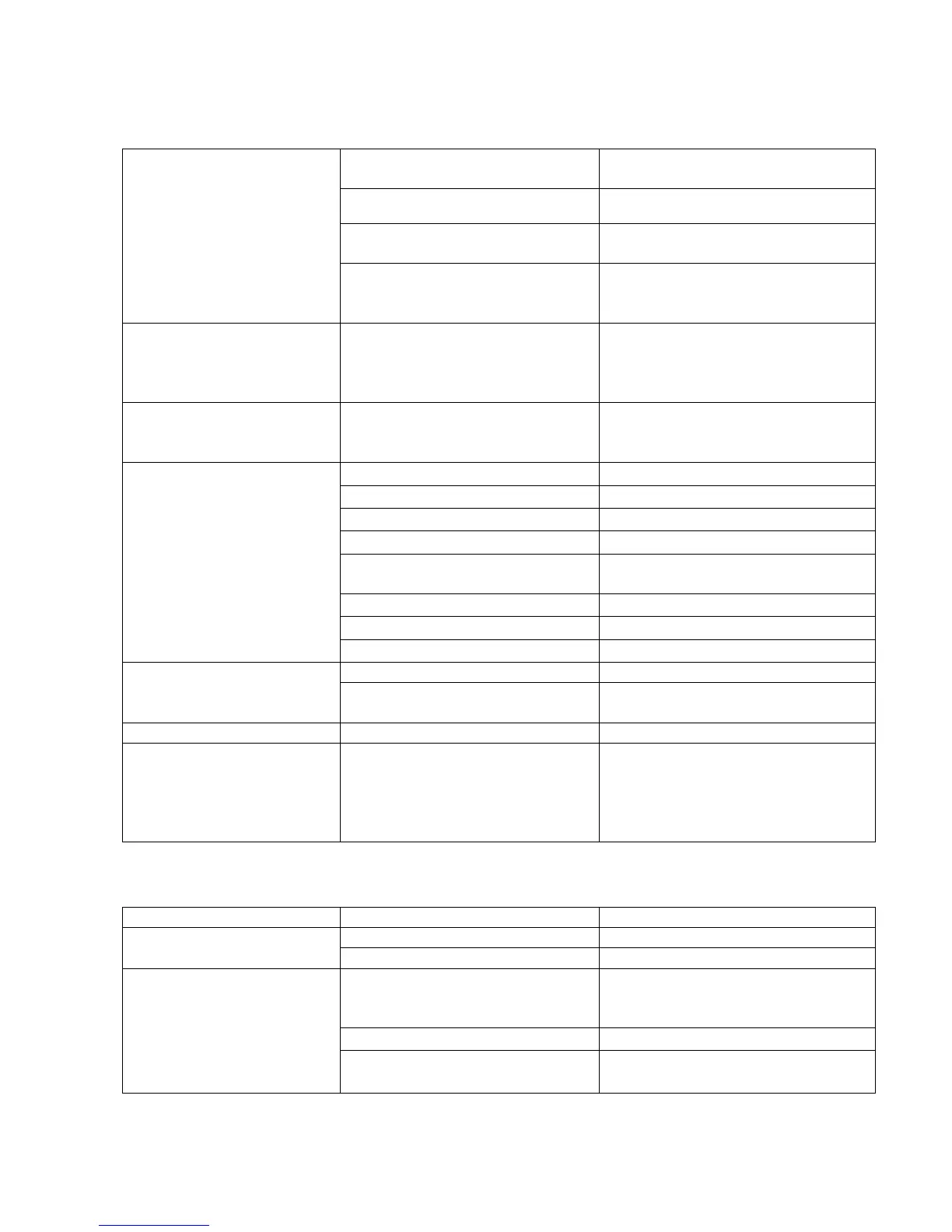

1. Throttle lever on/off switch in OFF

1. Turn throttle lever to ON position.

2. Fill fuel tank or turn on fuel supply.

3. Worn fouled or dirty spark plug.

3. Replace with factory recommended

spark plug.

4. Pressure build up in pump.

4. Squeeze trigger on spray wand

(refer to operating instructions in

Owner’s manual).

Engine oil level too low.

1. Place engine on level surface or

Fill crankcases with SAE 10W30 oil

(refer to engine manufacturers

instruction manual)

Engine runs well at no load

but “bogs” down under full

load

1. Engine speed is too slow.

1. Adjust Throttle Lever back to full

throttle

Engine will not start; or starts

and runs rough

1. Fill crankcase to proper level.

2. Clean or replace air cleaner.

4. Drain petrol tank, fill with fresh fuel.

5. Spark plug wire not connected to

spark plug.

5. Connect wire to spark plug.

7. Drain petrol tank, fill with fresh fuel.

8. Open choke fully and crank engine.

Engine shuts down during

operation

2. Fill crankcase with oil, to proper

level.

Engine “putts” or falters

1. Choke is opened too soon

1. Move choke to halfway position until

engine runs smoothly.

* All engine servicing to be taken to

Manufacturer’s authorized service

outlet.

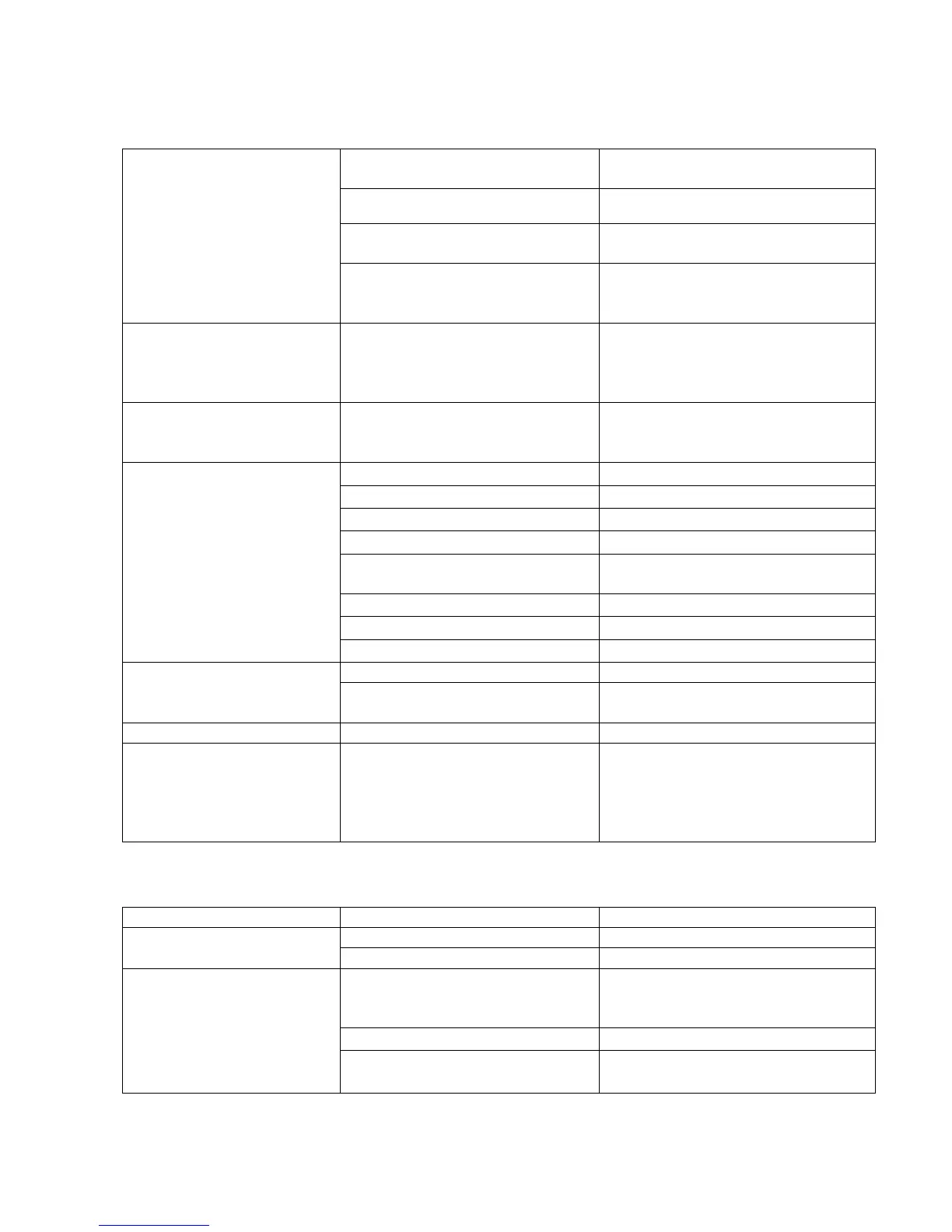

No low pressure detergent

delivery.

1. Insert black soaper nozzle.

2. Siphon hose or filter is plugged.

machine does not reach

required pressure.

1. Restricted or insufficient water

supply.

1. Check supply hose, faucet and inlet

water filter. Must be connected to

water source which provides 6 GPM.

2. Unsuitable or worn out nozzle.

3. Regulator set too low.

3. Reset unloader by turning knob

(clockwise increases pressure).

Loading...

Loading...