71020 & 70554 Chipper Shredder Owners ManualPage 10

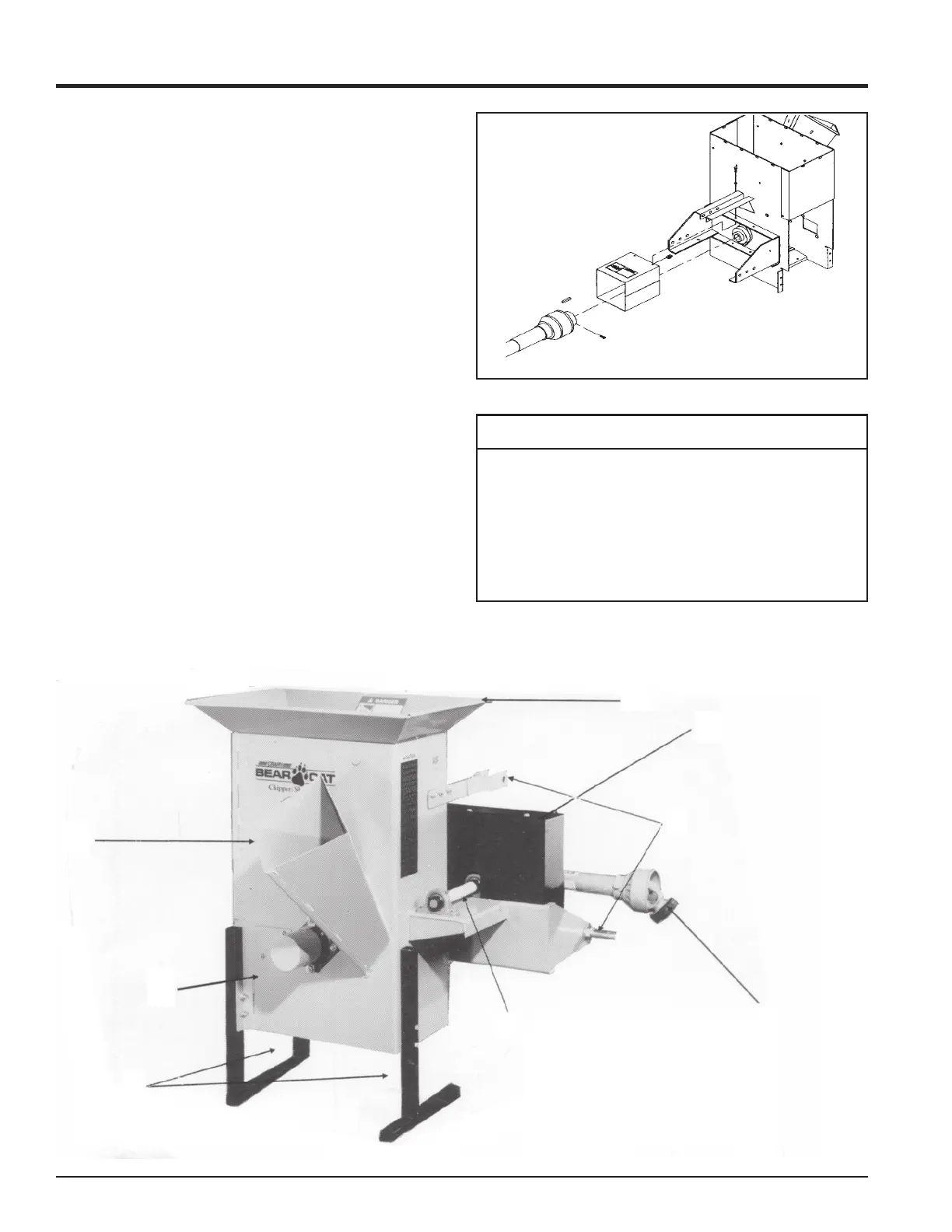

B

3

D

4

2

1

C

A

3.2 PTO MODELS

1. 3 pt. Hitch Connections. Mount chipper/shredder to

tractor. Connect direct for categories 0 & 1. A bush-

ing kit must be installed on 3 pt. connections for

category 2 hitches.

2. PTO Shaft. Connects tractor PTO to chipper/

shredder drive shaft. Avoid angle greater than 15

degrees up or down when unit is in use.

3. Leg Stands. Adjustable to allow proper driveshaft

angle. Do not move machine unless the legs are

clear and off the ground.

4. Jackshaft. Used for correct belt tension adjustment.

3.3 COMMON PARTS

A. Shredder Hopper. Material to be shredded is fed

through the hopper to the shredding knives.

B. Chipper Chute. Material to be chipped is fed through

the chipper chute to the chipper blades.

C. Drive Belt Shield. Never remove shield while the unit

is running.

D. Rotor Access Cover. Used to remove chipper blades

and service rotor assembly.4.0

Controls

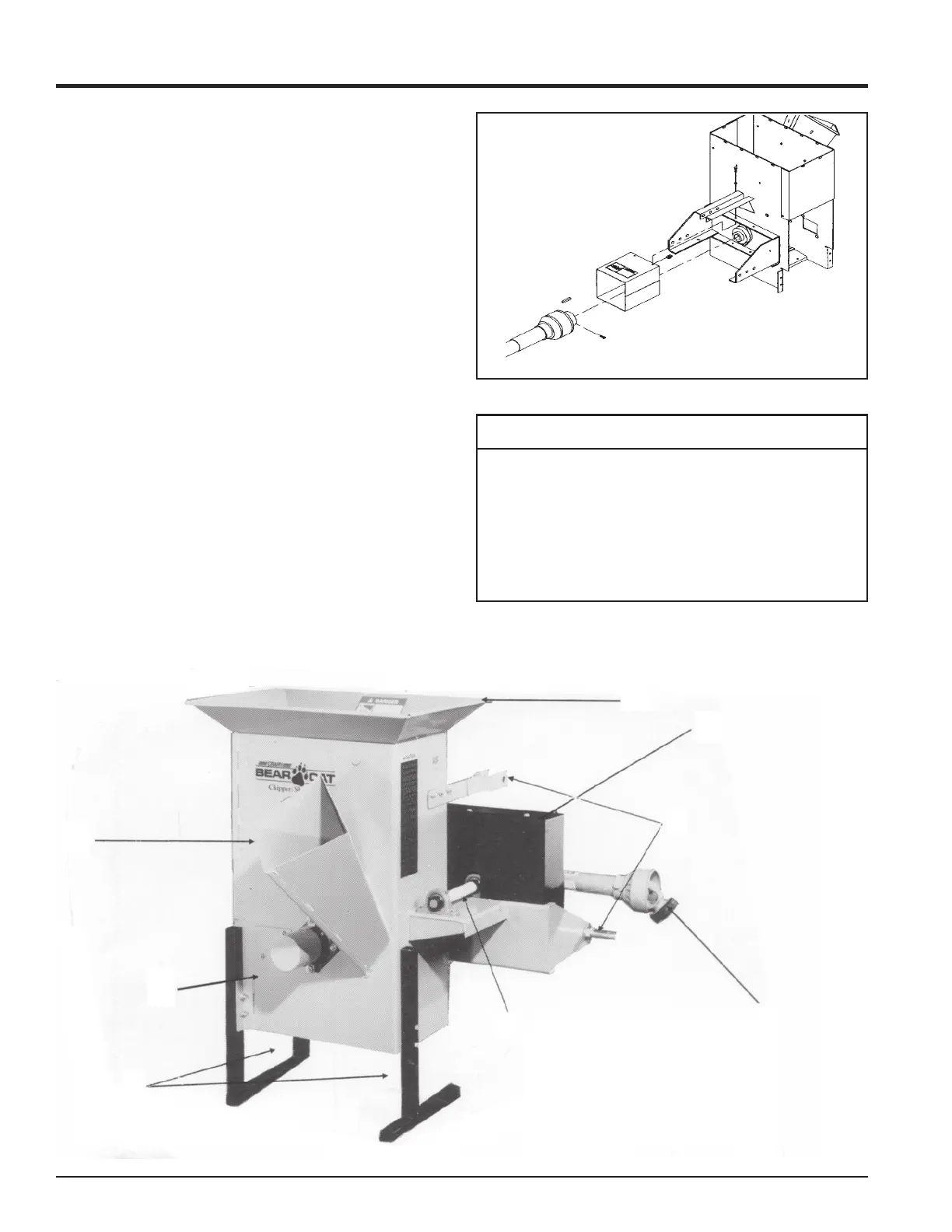

Fig. #10, unclutched PTO shaft kits

Fig. #11, PTO Chipper Shredder

(See Fig. #9) There are two different types of

unclutched PTO shaft kits available for the 2000 RPM

units. Check the PTO end of your tractor to determine

if you need a Male Drive Shaft Kit (P/N 70912) or a

Female Drive Shaft Kit (P/N 70913). There is a

Clutched PTO shaft Kit (P/N 70885) for tractors with

electric brake on the PTO.

NOTE

Loading...

Loading...