meters)

of

clearance at

the

rear and sides

of

the

Monitor

(see

Figure

3-1

).

As noted above,

don't

place the

Monitor

on long, plush carpet

or

spongy material where the

base

plate

might

come

in

contact

with

the

mounting

surface and

restrict the air circulation. Never

allow

paper

or

other

material

to

be

stored under

the

ter-

minal where

it

may cover fan screen and

re-

strict

air

flow

.

Care

must

be

used

to

ensure

that

the fan screen does

not

become

bent

and interfere

with

the fan.

3.5.2 Power Connection

It

is

rernrnr::enrlcd

that

instrument

panels

and cabinets

he

grounded

to

protect

operating

and servicing personnel. The SUPER BEE

is

shipped

with

a shielded three-conductor power

cord

which, when plugged

into

an

appropriate

outlet,

grounds the

instrument

through the

offset pin.

To

operate the SUPER BEE

from

a

two-contact

outlet,

us~

a three-conductor

to

two-conductor

adapter. Preserve the safety

feature

by

grounding the adapter pigtail lead.

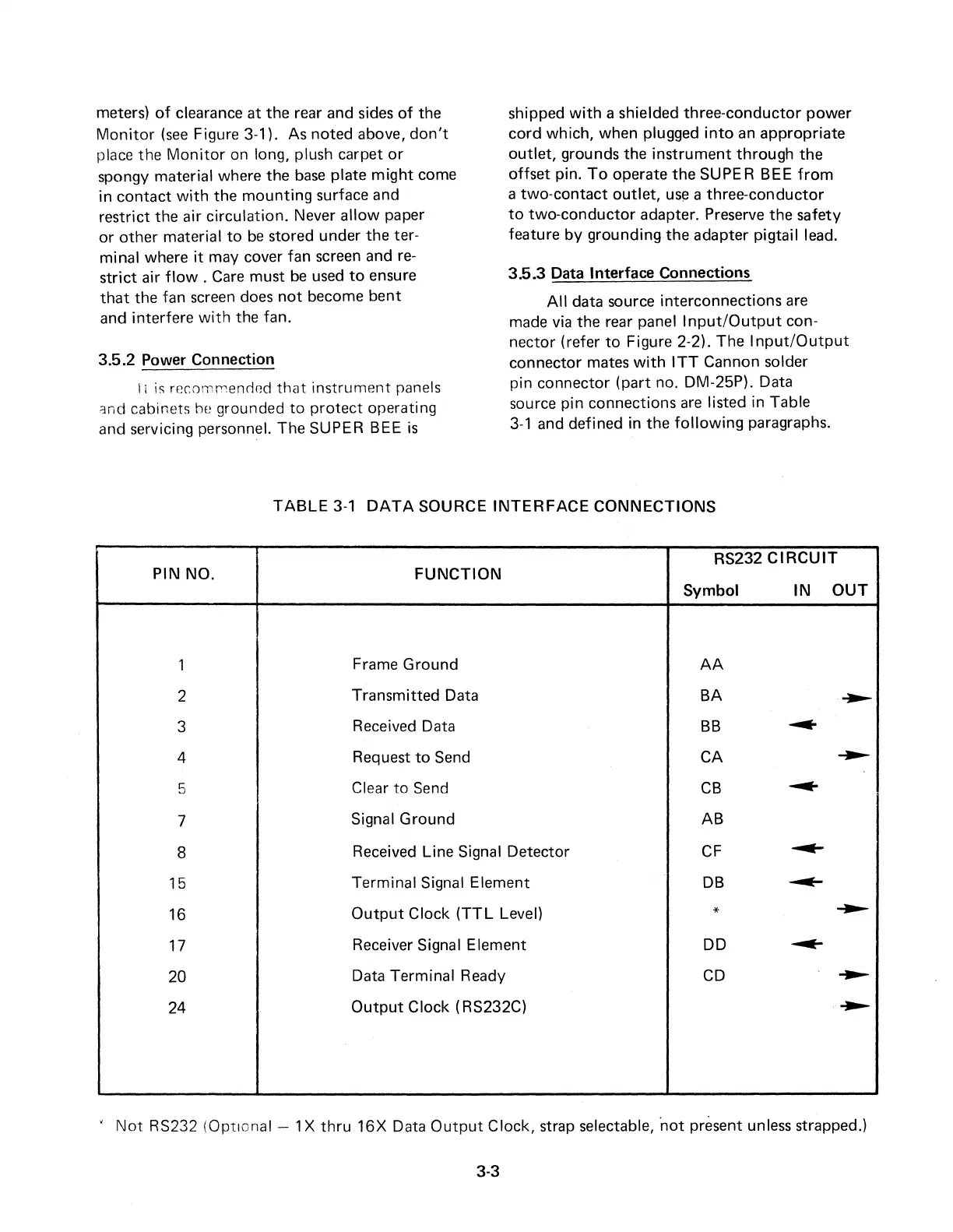

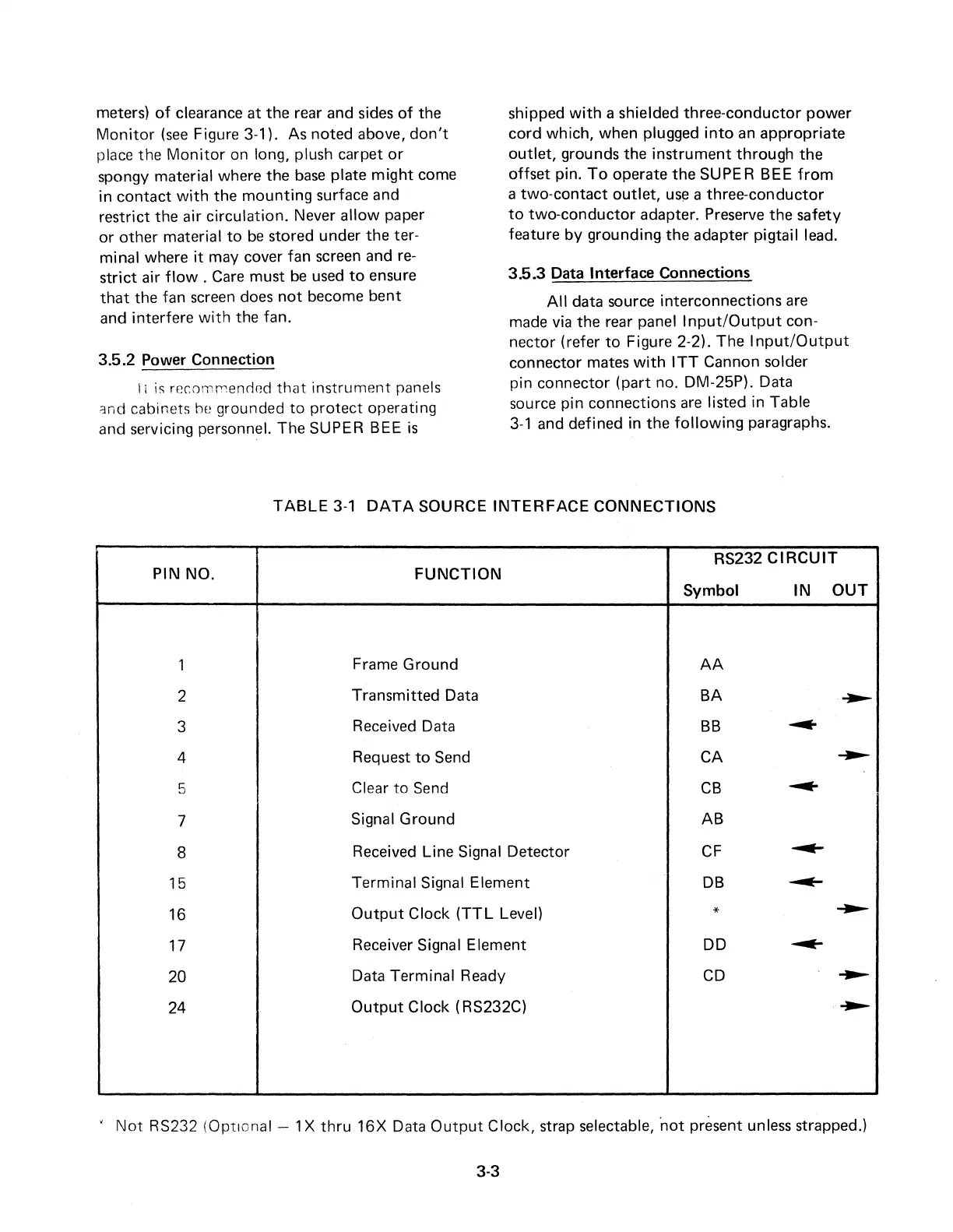

3.5.3

Data Interface Connections

All

data source interconnections

are

made

via

the rear panel

Input/Output

con-

nector (refer

to

Figure 2-2).

The

Input/Output

connector mates

with

ITT

Cannon solder

pin connector

(part

no. DM-25P). Data

source pin connections

are

listed in Table

3-1

and defined in the

following

paragraphs.

TABLE

3-1

DATA

SOURCE

INTERFACE

CONNECTIONS

RS232

CIRCUIT

PIN NO.

FUNCTION

Symbol

IN

OUT

1

Frame Ground

AA

2

Transmitted Data

BA

~

3

Received Data

BB

~

4

Request

to

Send CA

~

5

Clear

to

Send

CB

---

7

Signal Ground AB

8

Received Line Signal Detector

CF

---

15

Terminal Signal Element

DB

~

16

Output

Clock

(TTL

Level)

*

~

17

Receiver Signal Element DD

---

20

Data Terminal Ready

CD

---

24

Output

Clock (RS232C)

~

'

Not

RS232 (Optional - 1 X

thru

16X

Data

Output

Clock, strap selectable, ·not present unless strapped.)

3-3

Loading...

Loading...