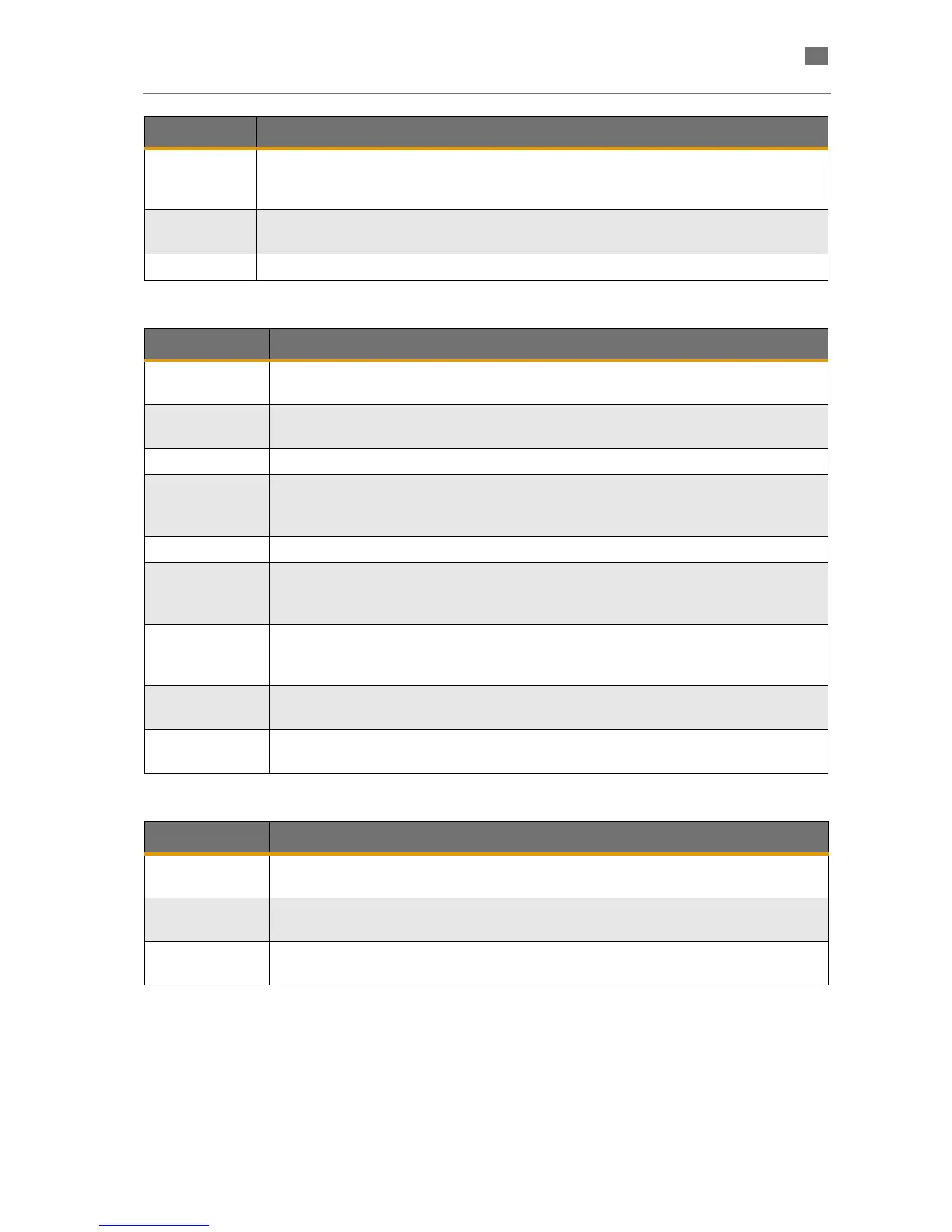

Warnings

Notes

E 41

(sparking in cru-

cible)

Pyrometer malfunction

Hairline crack in crucible

insert

Caution! Very hot parts!

Clean viewing window (

→ p. 45).

Replace crucible insert.

E 42 Pyrometer malfunction * Close hinged screen (→ p. 24).

Check optical waveguide for damage.

E 50 Safety circuit defective Notify Customer Service.

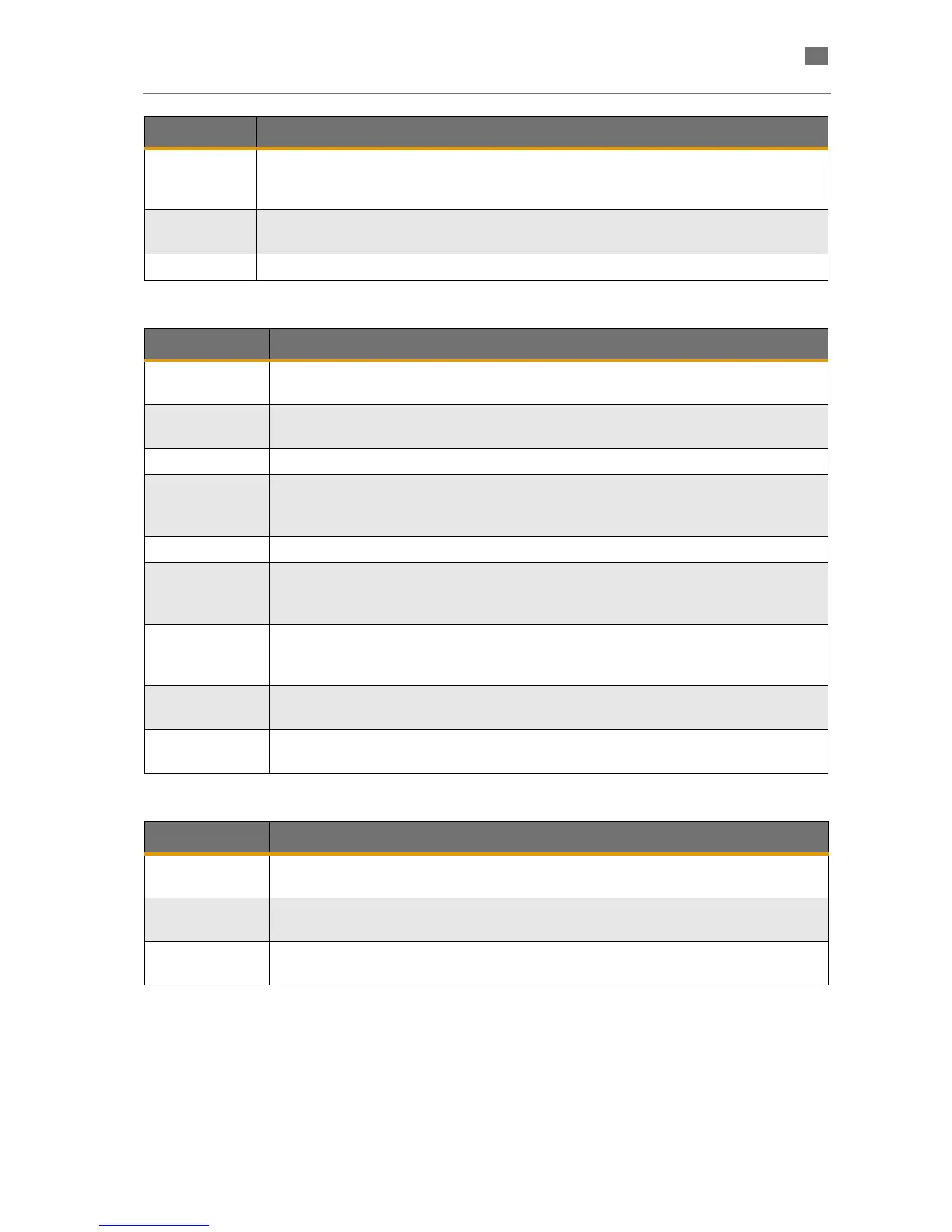

Failure report Cause Elimination

Failure report Cause Elimination

W 02 Compressed air malfunction * Switch on compressed air supply

or switch off other compressed air loads.

W 04 Crucible has not opened

completely.

* Check crucible and its handles for correct seating

(

→ p. 20).

W 10 Chamber not tight Clean seals (O-ring seals) (

→ p. 46).

W 11 Pressure rise too slow Check compressed air supply ≥ 5 bar (100 l/min).

Possibly install compressed air reservoir (

→ p. 17).

Clean gaskets and seals (

→ p. 46).

W 12 Pressure rise too rapid * Notify Customer Service.

W 13 Maximum vacuum was not

reached

Check compressed air supply ≥ 5 bar (100 l/min).

Clean ejector nozzle (

→ p. 48).

Replace the air filter (

→ p. 49).

W 14 Maximum mould pressure

was not reached

Check compressed air supply ≥ 5 bar (100 l/min).

Possibly install compressed air reservoir

→ p. 17).

Clean gaskets and seals (

→ p. 46).

W 15 Cooling water temperature

becomes critical

* Allow machine and cooling water to cool down while

the unit is powered on.

W 16 Chamber not tight Clean gaskets and seals (

→ p. 46). If the service mes-

sage still persists, notify the Customer Service.

Failure report Cause Elimination

H 01(every 100

castings)

Clean window

→ p. 45

H 77 (every

10,000 castings)

Maintenance required Notify Customer Service.

H 99 (after 50,000

castings)

Maintenance required Notify Customer Service.

Loading...

Loading...