Unit description

NAUTILUS

®

CC plus and NAUTILUS

®

T - Compact tabletop casting units with inte-

grated cooling and user-friendly touchscreen

Both units utilise tried-and-tested HF vacuum

pressure casting with split crucible and have

integrated cooling as well as user-friendly touch-

screens.

Special emphasis was placed on security systems

with double redundancy. The closing of both casting

chambers is indicated by the double closing sound.

To lower energy consumption during longer periods

of non-use, both units have an eco mode that starts

after 3 minutes and ends after 10 minutes with the

switching off of the touchscreen illumination. In this

state, Nautilus

®

requires only 10 W. A quick touch

on the touchscreen is enough to make the unit

functional again after a few seconds.

New software versions can be transmitted via a

USB interface on the back of the unit which means

both casting units are, therefore, "updatable".

In addition, NAUTILUS

®

CC plus has a pyrometer

that not only measures the temperature of the melt

without contact. Together with specially developed

software, it also makes it possible to largely

automate the casting process. This makes repro-

ducible quality during casting possible, that can also

be documented and archived in the form of casting

protocols via the USB interface. In the event of

malfunctions, it is also possible to call up diagnostic

protocols and send them to the BEGO Service.

For easier handling of these additional features that

the USB interface provides, a USB docking station

and a USB stick is also supplied with NAUTILUS

®

CC plus.

Determination of the casting temperature for dental alloys with NAUTILUS

®

CC

plus

The flowability of the melt and thus the casting

temperature are of decisive importance for the

quality of the cast object. The problems that may

result due to a melt that is too cold or too hot are

known in practice and described in the relevant liter-

ature and therefore they are not dealt with in detail

here.

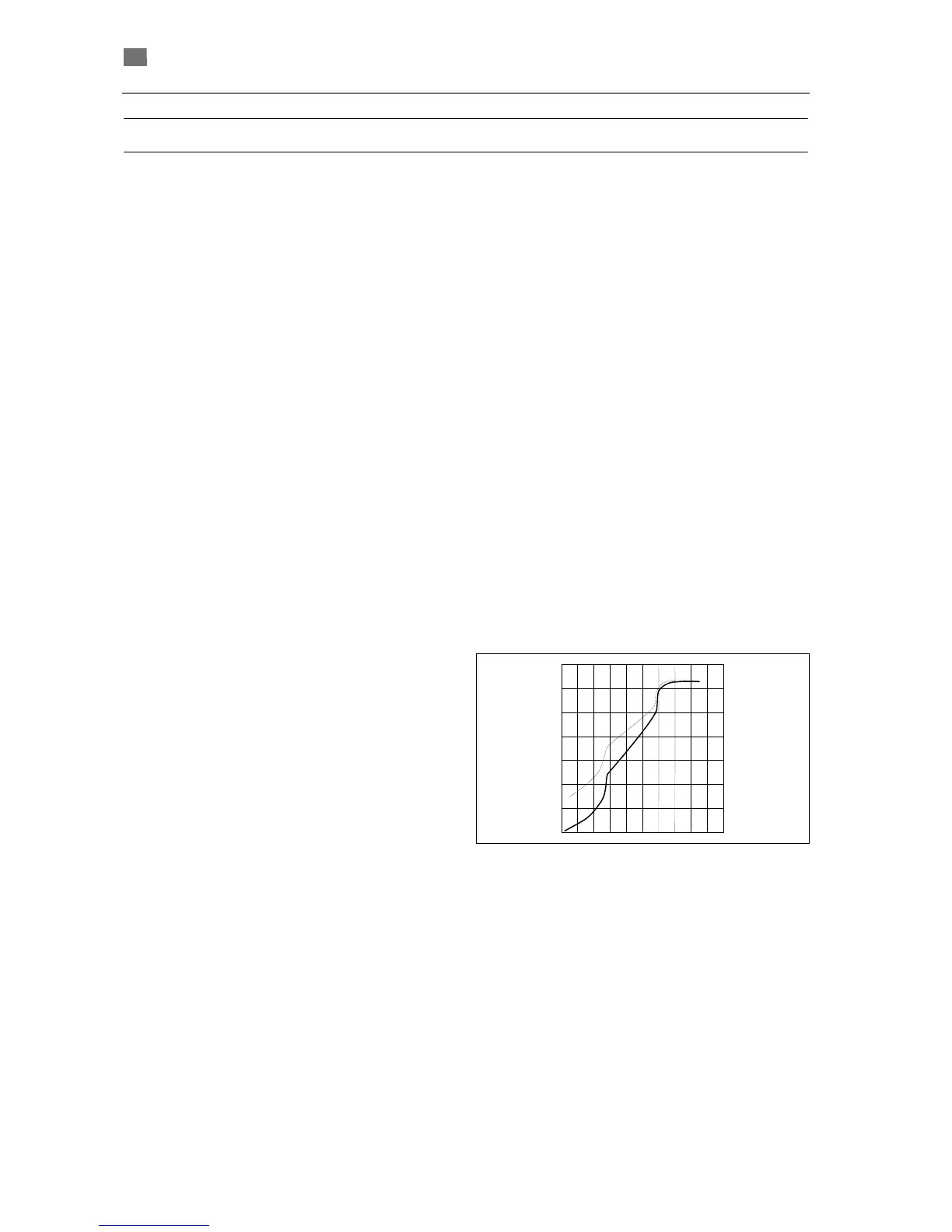

Dental alloys have the property of not having a fixed

melting point, but a melting interval. Within the

melting interval alloys occur in viscous as well as in

crystalline form.

The melting interval can easily be identified in the

melting and hardening curve by the characteristic

"salient points", which result due to irregularities in

the temperature curve.

When an alloy is melted, the first "salient point" is

the so-called solidus and the second the liquidus,

from which point the alloy exists entirely as a melt.

These characteristics in the temperature curve are

utilized by NAUTILUS

®

CC plus by means of a

thermal analysis process.

To ensure optimal flowability of the melt in the dental

casting mould, the melt is heated beyond the

liquidus point. Depending on the casting method

and alloy, a temperature increase between 100°C

and 180°C has proven to be optimal in practice.

Corresponding recommendations on these casting

temperatures, which have been verified by empirical

tests as a rule, are given by the manufacturers of

alloys and casting equipment. With most casting

machines the accuracy for achieving the recom-

mended casting temperature through visual

assessment of the developing temperature still

depends on the individual skills of the user.

Loading...

Loading...