OPERATION

OPERATING COMPONENTS

DEF & LIM Trigger & Detection

Emission related warnings and failures lead to

indicator signals and torque reduction of the

engine. Inducement is a mandatory process

required if NOx emissions exceed a certain

threshold.

Events which effect NOx emissions are therefore

primary factors for an inducement strategy:

–DEFTankLevel

– DEF Quality

– NOx Monitoring System

– Dosing Interruption or Tampering

Certain values are monitored and if the appointed

thresholds are violated, the inducement takes

place. These results in a reduced maximum engine

torque/speed and besides this, several different

indicator lamps are activated to inform the driver

about the changed vehicle status. The different

indication lamps are provided as followed:

Tampering & Incorrect Adblue /

DEF Quality

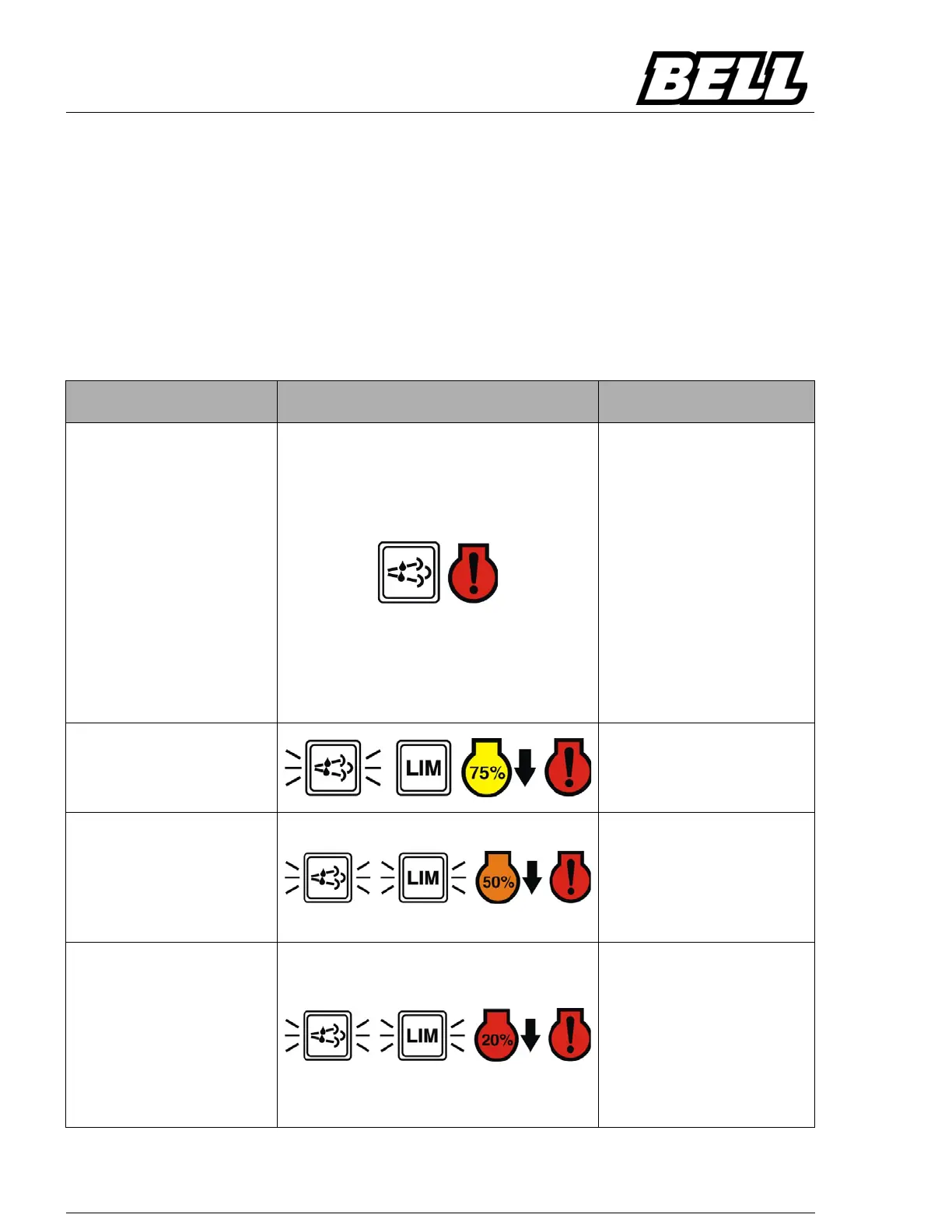

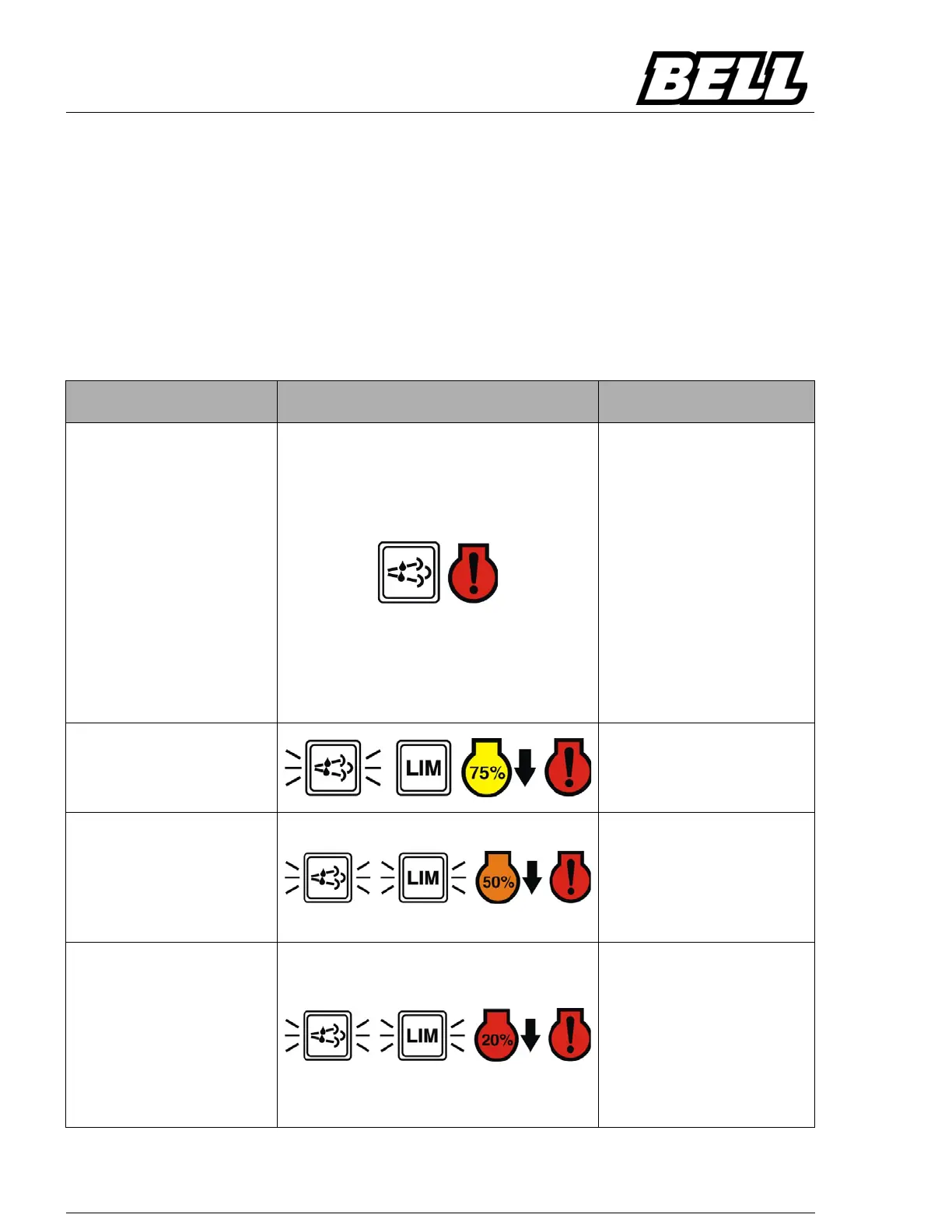

Symbol Displayed on CDU System Reaction / Response

Trigger: Detection

• Disconnect tank level sensor

• Disconnect Adblue dosing line or

valve

• Blocked Adblue dosing line or

valve

• Disconnect Adblue dosing pump

• Disconnect SCR Wiring Harness

• Disconnect NOx Sensor

• Disconnect Adblue Temperature

Sensor

• Disconnect exhaust temperature

Sensor

Adblue Warn ON

60 Min After Trigger

Adblue Warning - Blinking

Engine Warning Light - ON

LIM Warning - ON

150 Min After Trigger

Adblue Warning - Blinking

Engine Warning Light - ON

At torque > 50% - LIM Warn - ON

At torque < 50% - LIM Warning -

Blinking

230min after trigger

DEF Lamp flashing 1Hz,

LIM Lamp flashing 1Hz,

AWL solid,

Stop Engine Lamp solid,

maximum available engine torque is

reduced to 20% of peak torque and

maximum speed is reduced idle

speed.

Loading...

Loading...