3.0 Installation

It is strongly

advised

that

the

installer reads Section 2

and

Section 3 of this

manual

prior

to

starting

any

installation work.

It

is a requirement that only qualified

and

competent

personnel

may

undertake

instal1ation, commissioning,

and

servicing.

Warning

Always

ensure

that

the

appropriate

personal

protective

equipment

is

used.

3.1 Packaging/siting

The heater will usually be

supplied

wrapped

in heavy

gauge

polythene, non-assembled

parts

will be

supplied

separately. Prior to installation, the assembly of

the

heater

should

be completed, it

is advisable that this is

undertaken

in

the

area

where

the

heater is scheduled to be sited.

Caution

It

is

strongly

advised

that

when

positioning

the

heater

the

lifting

eyes

are

used,

thereby

reducing the risk of

inadvertent

damage

being

occasioned to the heater.

Prior to installation the heater

must

be

correctly positioned before

any

final assembly

work

is

completed. The

bonnet

top

and

outlet nozzles

must

be securely

attached

before installation can

commence.

3.2 Flooring

The

heater

must

be

installed

on

a level

non

combustible

surface

capable

of

supporting

the

weight of the heater

and

any

ancillary equipment.

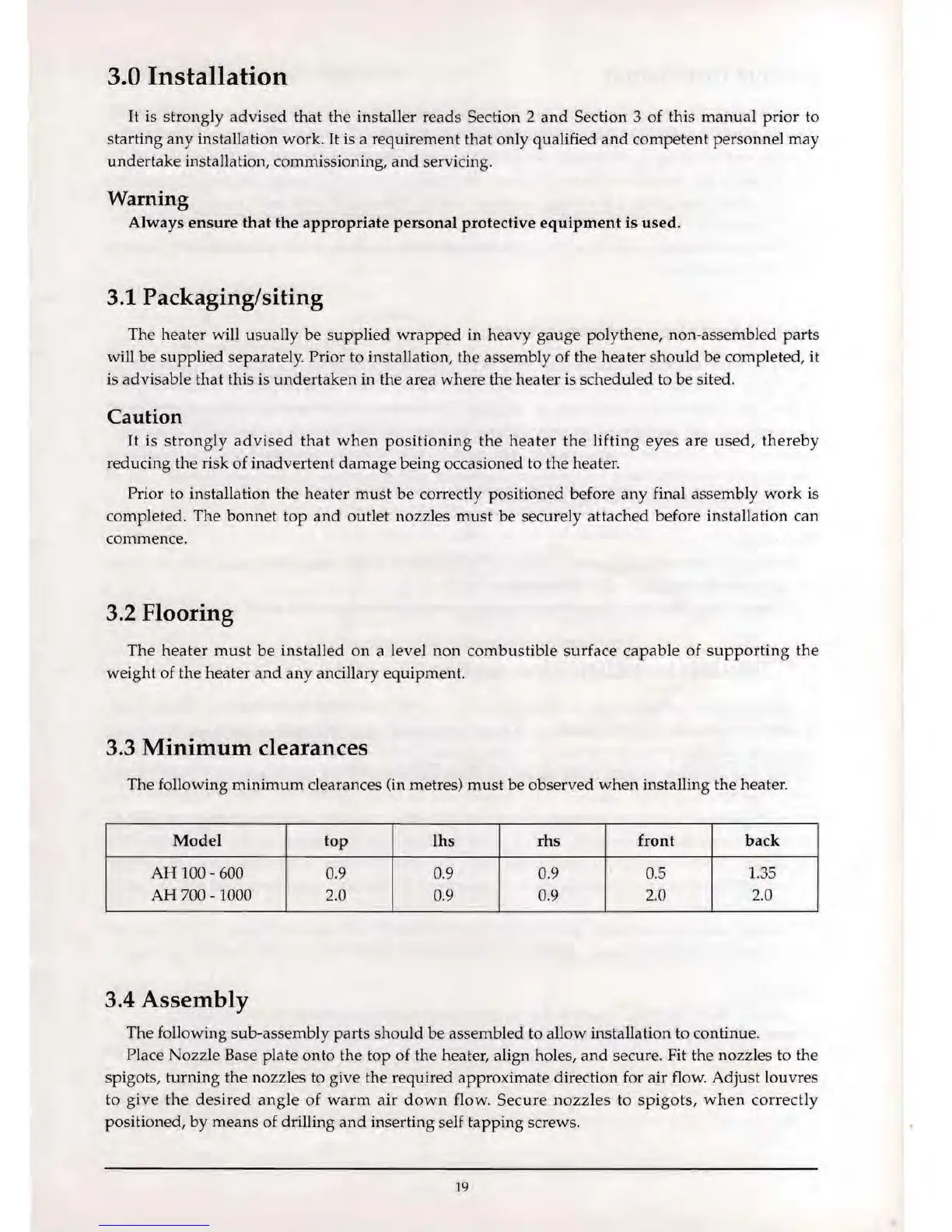

3.3

Minimum

clearances

The following

minimum

clearances (in metres)

must

be observed

when

installing the heater.

'

Model

top

lhs

rhs

front

back

AH

100 - 600

AH

700 -1000

0.9

2.0

0.9

0.9

0.9

0.9

0.5

2.0

1.35

2.0

[

3.4

Assembly

The following sub-assembly

parts

should

be assembled to allow installation to continue.

Place Nozzle Base plate

onto

the top

of

the heater, align holes,

and

secure. Fit the nozzles to the

spigots,

turning

the nozzles to give the required

approximate

direction for air flow. Adjust louvres

to

give

the

desired

angle

of

warm

air

down

flow.

Secure

nozzles

to

spigots,

when

correctly

positioned,

by

means

of drilling

and

inserting self

tapping

screws.

19

Loading...

Loading...