3.0

Installation

It

is

strongly

advised

that

the

installer

reads

Section 2

and

Section 3 of this

manual

prior

to

starting

any

installation work. It is a

requirement

that only qualified

and

competent

personnel

may

undertake

installation, commissioning,

and

servicing.

3.1

Packaging/siting

The

heater

will

usually

be

supplied

wrapped

in

heavy

gauge

polythene, non-as

sembled

parts

will be

supplied

separately.

Prior

to installation, the

assembly

of the

heater

s

hould

be

completed,

it

is

advisable

that this is

undertaken

in the area ""here

the

heater

is

scheduled

to be sited.

Caution

It

is

strongly

advised

that

when

positioning

the

heater

the

lifting

eyes

are

us

ed,

thereby

reducing

the risk of

inadvertent

damage

being

occasioned to

the

heater.

The

heater

will

usually

be

supplied

wrapped

in

heavy

gauge

polythene,

with

non-a

s

sembled

parts

(outlet nozzles,

bonnet

top, etc.)

supplied

separately. Prior to installation the

heater

must

be

correctly

positioned

before

any

final

assembly

work

is

completed

.

The

bonnet

top

and

outlet

nozzles

must

be

securely attached before installation

can

commence.

3.2 Flooring

The

heater

must

be

installed

on

a level

non

combustible

surface

capable

of

supporting

the

weight

of

the

heater

and any

ancillary

equipment

.

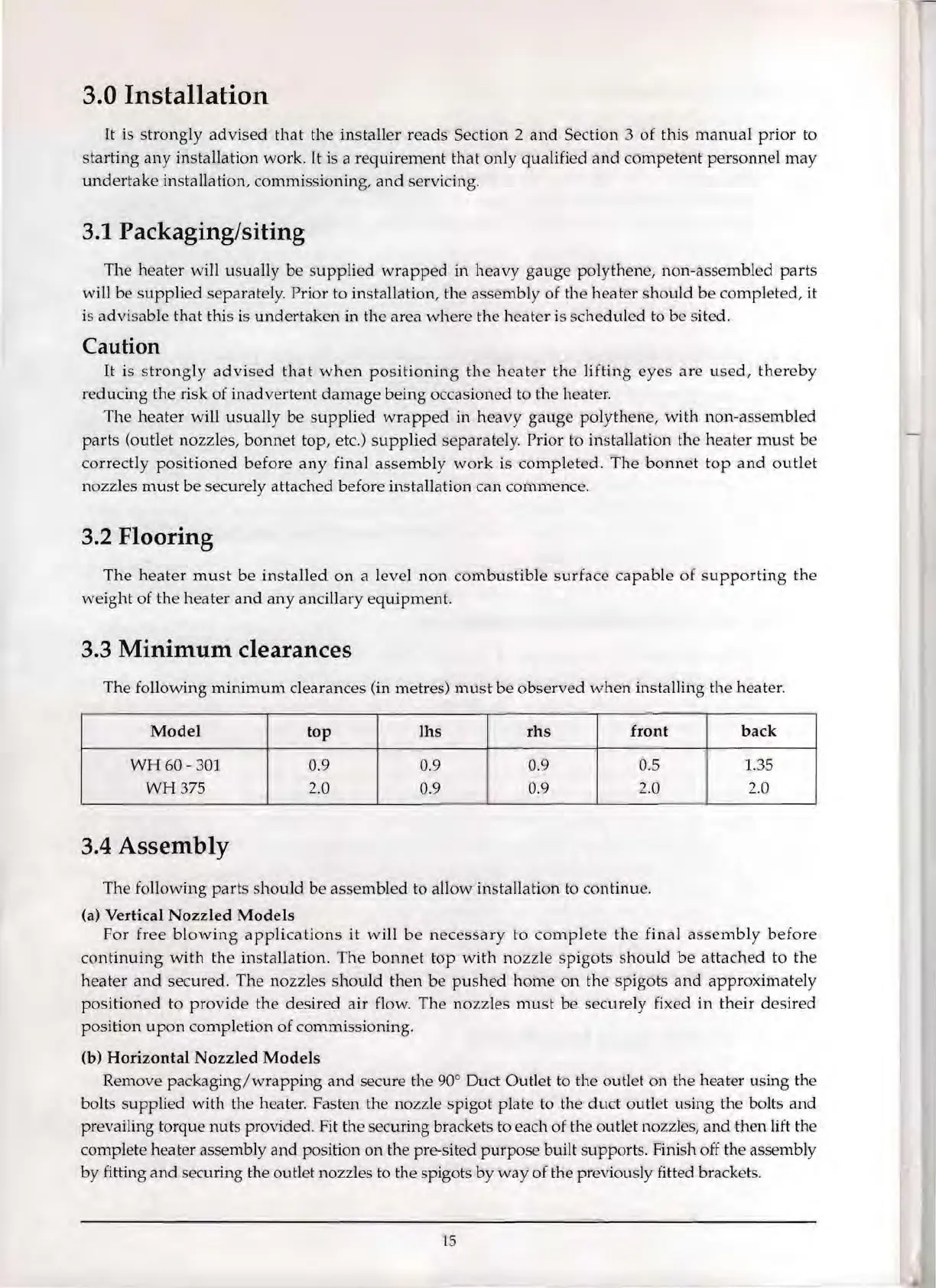

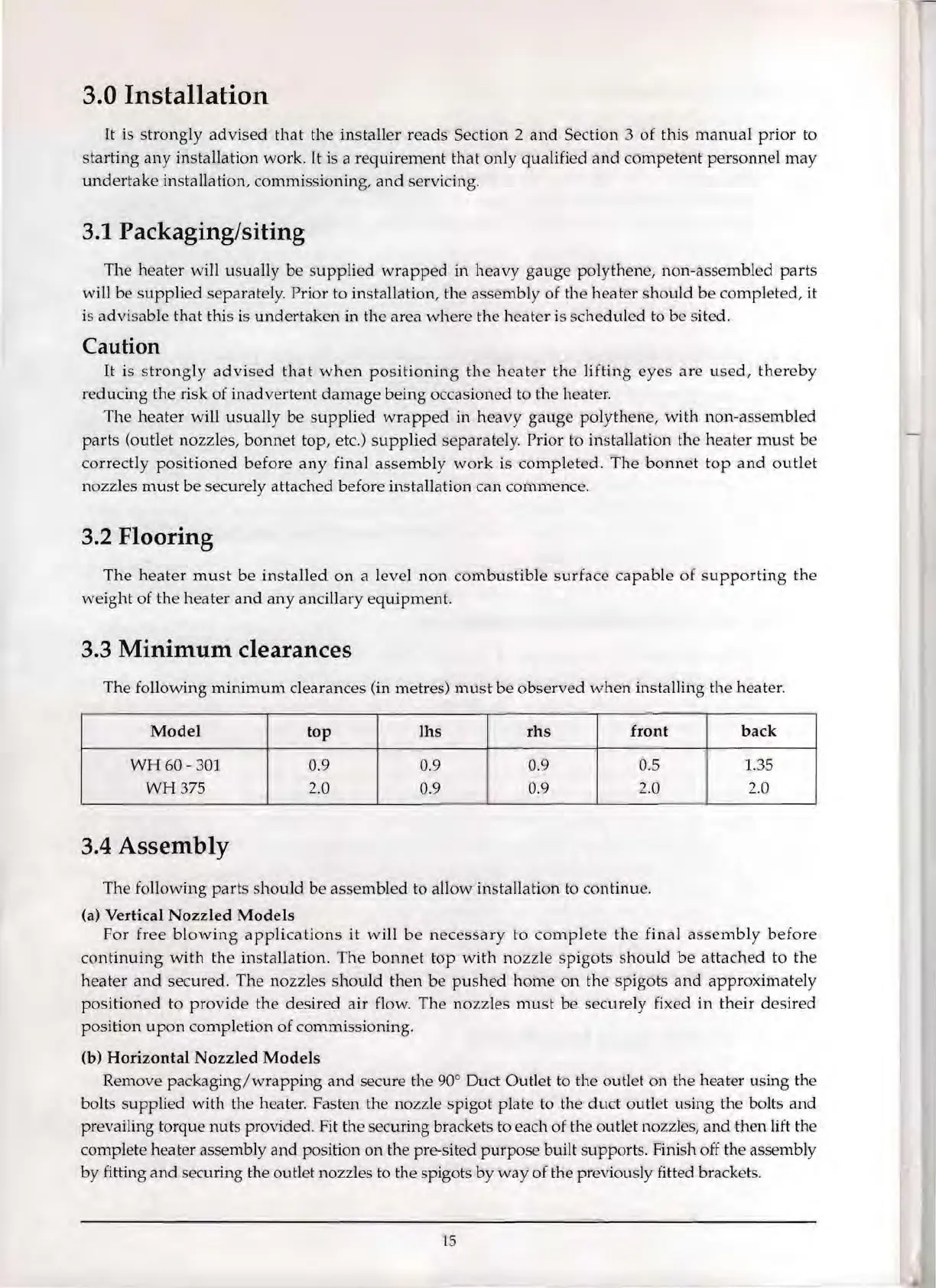

3.3

Minimum

clearances

The following

minimum

clearances (in metres)

must

be

observed

,.

"hen

installing the heater.

Model

top

I

lhs

rhs

front

back

WH

60-

301

WH375

0.9

2.0

0.9

0.9

0.9

0.9

0.5

2.0

1.

35

2.0

3.4

Assembly

The following

parts

should

be

assembled

to

allow

installation to continue.

(a) Vertical

Nozzled

Models

For

free

blowing

applications

it

will

be

necessary

to

complete

the

final

assembly

before

continuing

with

the

installation.

The

bonnet

top

with

nozzle

spigots

should

be

attached

to the

heater

and

secured. The nozzles

should

then

be

pushed

home

on

the

spigots

and

approximately

positioned

to

provide

the

desired

air

flow. The

nozzles

must

be

securely

fixed in

their

desired

position

upon

completion

of commissioning.

(b)

Horizontal

Nozzled

Models

Remove

packaging/wrapping

and

secure the

90°

Duct Outlet to the outlet

on

the heater using the

bolts

supplied

with

the heater. Fasten the nozzle spigot plate to the

duct

outlet using the bolts

and

prevailing torque nuts provided. Fit the securing brackets to each of the outlet nozzles,

and

then lift the

complete heater assembly

and

position on the pre-sited

purpose

built supports. Finish off the assembly

by

fitting

and

securing the outlet nozzles to the spigots

by

way

of the previously fitted brackets.

15

Loading...

Loading...