EXPRESS DUAL • ED2000

© Bernhard and Company Limited

16

EXPRESS DUAL • ED2000

© Bernhard and Company Limited

17

6.5 Linking Up The Reel Drive Unit to the Reel

Machines are supplied with a compact reel drive motor/gearbox that is supported by a

bracket that mounts to the machine table. The support can be mounted on either end of

the table according to where the drive needs to be connected to the mower.

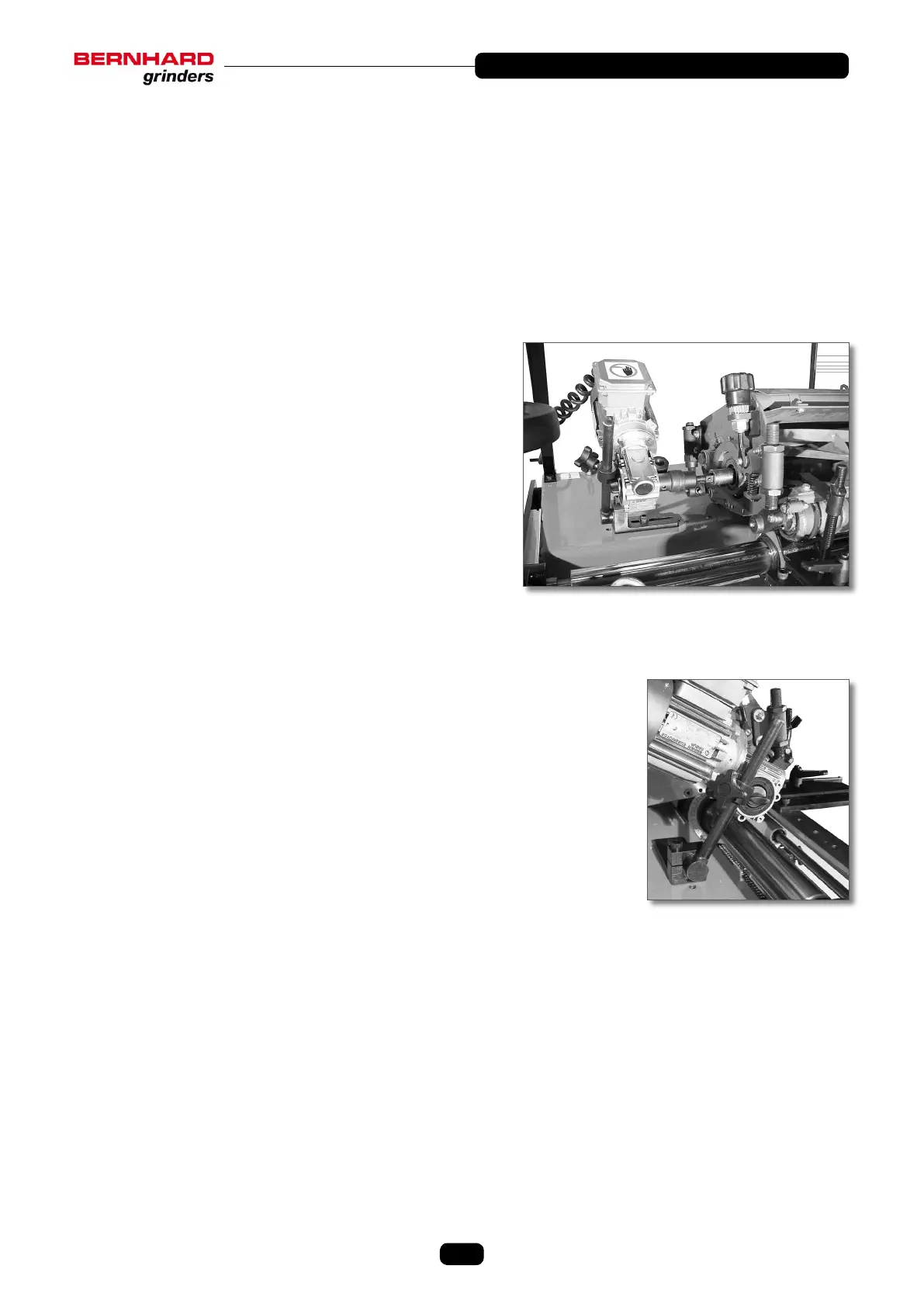

6.5.1 Select the attachment with which to

drive the reel. If the reel sprocket,

gear or pulley is secured with a nut

it may be easier to use a standard

socket together with a inch square

end driver. Ensure the nut is tight, as

the direction of rotation may tend to

unscrew it. Ensure that the drive shaft

is through the exible coupling/driver

before setting the machine on the table

and that the whole unit is at the correct

end of the table.

Alternatively it may be easier to drive directly onto the sprocket using one of the pin or

adjustable type sprocket drivers tted to the plain drive rod.

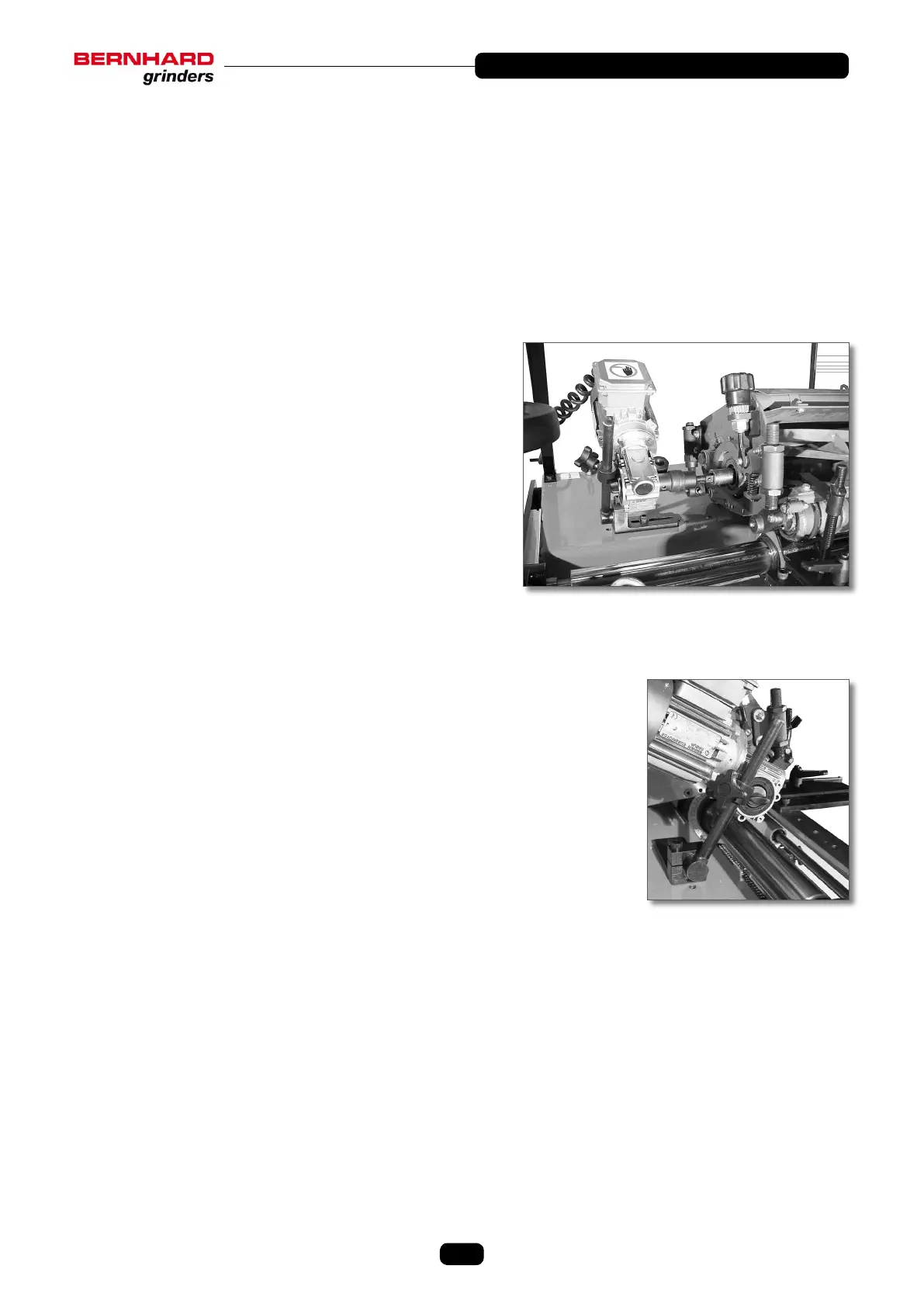

6.5.2. When the cutting unit is in place and rmly xed to the

front roller brackets, and the rear clamped. Position the

drive support unit left or right, using appropriate mounting

holes, so that the drive rod will reach the end of the reel

shaft. Tighten unit in place.

Adjust the height and position, forwards and backwards

and up and down, of the cable drive drive support so that

the shaft is square with the driven end of the reel, and

tighten clamps to hold it in place.

The black lobed hand screw allows the drive head to be

moved along the square support shaft to adjust the height

of the drive, while the hex socket “allen” screw allows

the support shaft to be clamped at any desired angle to

engage in the drive mechanism on the reel.

Plug the power lead into the socket (on the centre rear

of the machine – OR on the side of the unit that the reel

drive is positioned.)

Route the cable under the hooks provided to keep it clear

of the cutting unit

6. In-frame Grinding (Continued)

Loading...

Loading...