EXPRESS DUAL • ED2000

© Bernhard and Company Limited

22

EXPRESS DUAL • ED2000

© Bernhard and Company Limited

23

8. Maintenance (Continued)

NOTE When tting a new sleeve and nut, it may appear that the assembly is too tight to t onto

the mainshaft of the Express Dual.

This is because all replacement sleeve and nut assemblies are shipped with the drive key

left very slightly oversize to allow for varying degrees of wear in the mainshaft keyway.

(The key is “peened” (like riveting) into the sleeve NOT welded).

The key needs to be “tted” to the mainshaft. This may entail ling a small amount of

material from both the depth of the key and the sides. Remove only a very small amount of

material at a time, then check the t, until the sleeve and nut assembly slides freely along

the length of the mainshaft without any play between key and keyway.

REMEMBER

The mainshaft keyway will be less worn at the ends of the shaft than where the normal

traverse of the grindstone occurs, do not remove too much metal from the key.

NEVER grip the sleeve and nut assembly in a vice. Fully tighten the nut when the

assembly is tted to the mainshaft.

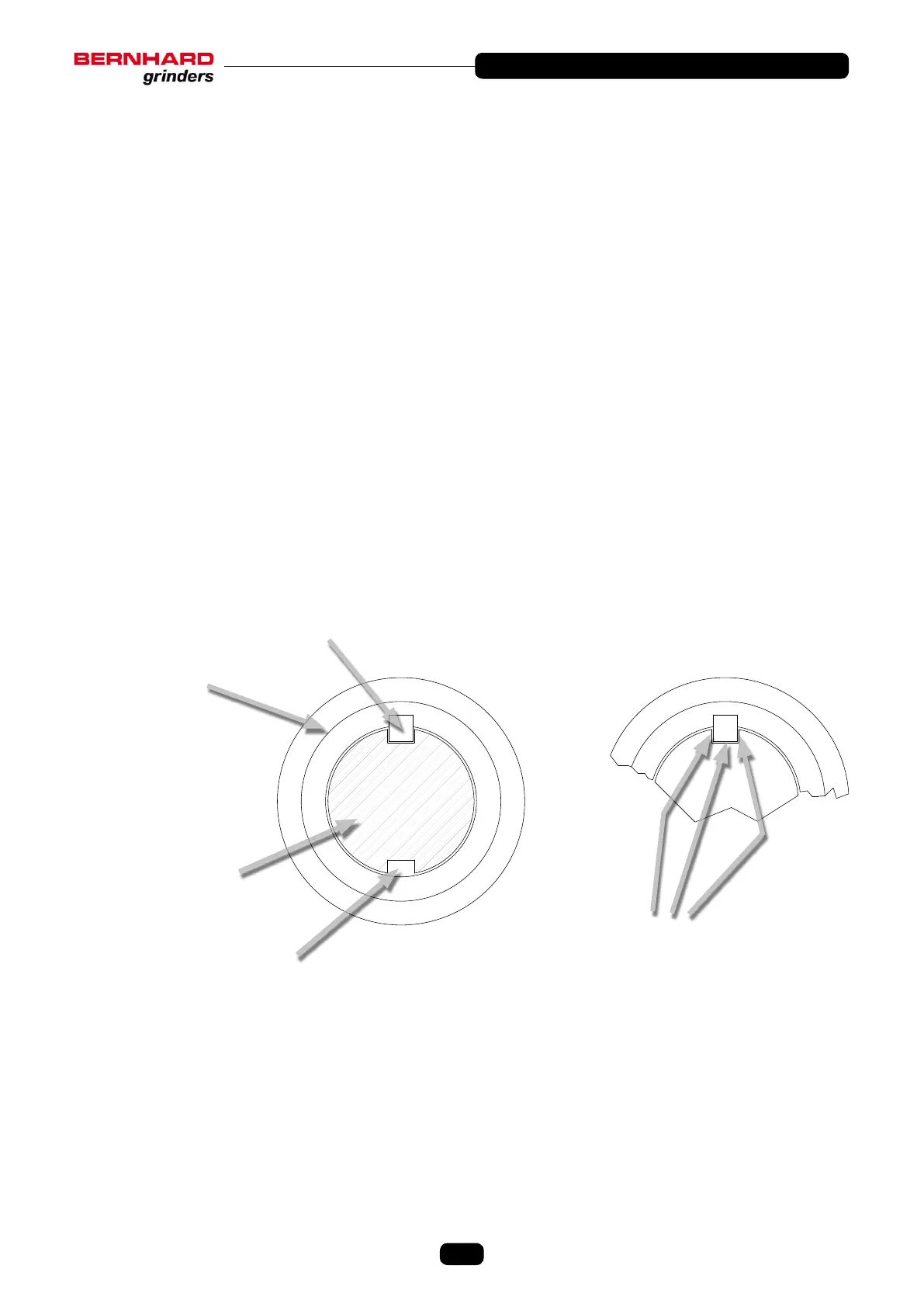

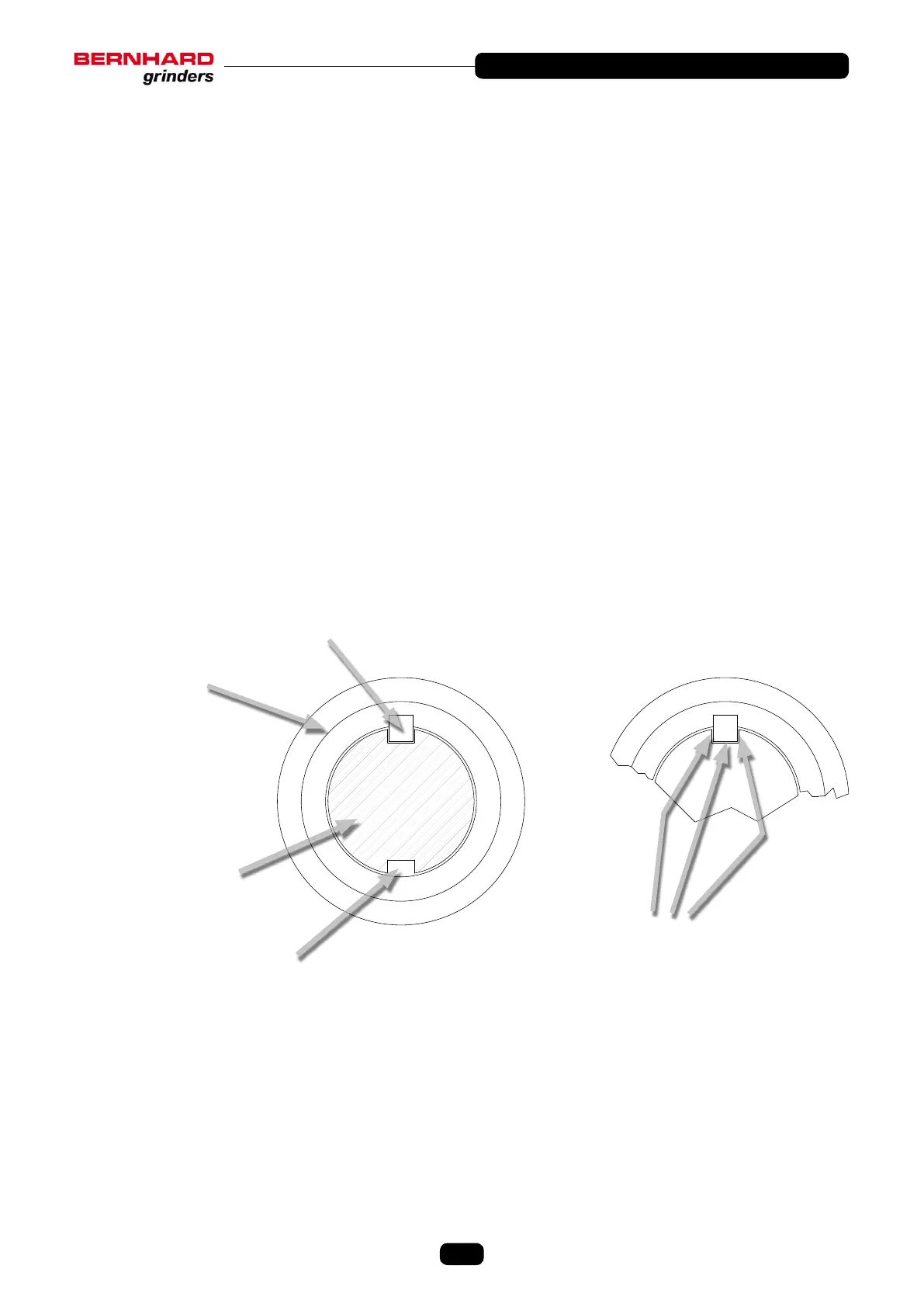

Sleeve

Key

Mainshaft

2nd Key

Remove minimal material from

sides and bottom of key

Loading...

Loading...