INSTALLATION MANUAL

2) GENERAL OUTLINE

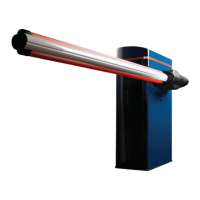

Compact electromechanical barrier suitable for limiting private areas, park-

ings, access areas for vehicles only. Available for passageways from 4 to 8

metres. Adjustable electronic limit switches, they guarantee correct boom

stopping position. In case of intensive use, a thermal sensor activates the

cooling fan.

The emergency release device for manual manoeuvre is controlled by a

personalised key lock.

The actuator is always supplied for left-hand side tting. However, when nec-

essary, the opening direction can be reversed by means of simple operations.

The BM mod. foundation base (on request) makes barrier installation easier.

Appropriate ttings make it easy to install accessories.

The LIBRA C MV control panel is supplied by the manufacturer with standard

setting. Any change must be set by means of the incorporated display or by

means of the universal programmer.

3) TECHNICAL SPECIFICATIONS

Power supply: 230V±10% 50/60Hz(*)

Power absorbed: 300W

Absorption (with accessories): 1 A

Internal lubrication:

permanent grease

Max torque: 600 Nm

Opening time: 6s (5-6m), 8s (8m)

Boom length:

4m (MICHELANGELO 40)

5-6m (MICHELANGELO 60)

da 6m a 8m (MICHELANGELO 80)

Impact reaction: encoder

Manual mechanical release: customised key

Type of boom: rectangular/round

Limit devices:

electrical incorporated and electroni-

cally adjustable

Type of use continuous operation

Working temperature: from -20°C to +55°C

Degree of protection: IP 24

Operator weight (without boom):

55 Kg (MICHELANGELO 40)

58 Kg (MICHELANGELO 60)

68 Kg (MICHELANGELO 80)

Dimensions: see g. A

Mains/low voltage insulation: > 2MOhm 500V

Dielectric strength:

mains/low voltage 3750V~ for 1

minute

Motor output current:

20A max (MICHELANGELO 40)

25A max (MICHELANGELO 60)

30A max (MICHELANGELO 80)

Cooling intervention

temperature:

80°C

Supply to accessories: 24V~ (180 mA max absorption)

Barrie-open warning light: 24V~ 3W max

Blinker: 24V~ 25W max

Fuses: see gure I-L

N° of combinations:

4 billion

Max. n° of remotes that

can be memorized:

63

(*)= special power supply voltages on request.

Usable transmitter versions:

All ROLLING CODE transmitters compatible with

4.1) FOUNDATION PLATE (Fig. B1).

4.2) FASTENING ANCHOR BOLTS (Fig. B2).

5) FITTING OF THE ACTUATOR

WARNING! The barrier must be exclusively used for vehicles to

drive through. Pedestrians must not walk within the operator

manoeuvring area. An appropriate pedestrian passageway must be

provided for.

The passageway must be suitably indicated by means of the warning

signs illustrated in Fig.A.

WARNING: before opening the door, the spring must be unloaded

(vertical boom). The door of the box must be facing towards the inside

of the property. When you stand in the middle of the passageway, facing

outwards, if the box is on your left, the barrier is left-hand tted, if the box

is on your right, the barrier is right-hand tted.

The actuator is always supplied for left-hand side tting.

5.1) COVER AND DOOR OPENING AND CLOSING (Fig. D).

5.2) POSITIONING OF ENCLOSURE FIG.E

5.3) BOOM FIXING (Fig. F).

6) MICHELANGELO 40-60 accessories: boom length limits and balancing

(Fig. G1).

For further information about the installation and use of accessories, refer

to the respective instruction manuals.

6.1) MICHELANGELO 80 accessories: Fig.G2.

6.2) BAR BALANCING (Fig. G3).

6.3) ATTACHMENT AND TENSIONING OF SPRING g. AC-AD

7) Right-hand tting (Fig. AA, AB)

- Carry out bar balancing as described in Fig. G3.

- Set the Direction Reversal logic to ON in the control panel.

Warning: the Direction Reversal logic must be congured to OFF for

left-hand tted barriers, and to ON for right-hand tted barriers.

Otherwise, the limit devices will not operate or an encoder direction

error will be displayed.

8) FITTING THE FLASHING LIGHT (FIG AE - AF)

Complete assembly and wiring as directed in instructions provided for

the ashing light

9) FITTING THE PHOTOCELL (FIG AF).

Complete assembly as directed in instructions provided for the photocell

----------------------------------------------------------

10) ELECTRICAL INSTALLATION SET-UP

WARNING: before opening the door, the spring must be unloaded (ver-

tical boom). Set up the electrical installation (g. A) with reference to the

current regulations for electrical installations. Keep the mains power supply

con-nections denitely separate from the service connections (photocells,

electric edges, control devices etc.).

Warning! For connection to the mains, use a multipolar cable having

minimum 3x1.5mm

2

cross section and complying with the previously

mentioned regulations (for example, if the cable is not protected, it

must be at least equal to H07 RN-F, whereas if it is protected it must be

at least equal to H07 VV-F with a 3x1.5 sq mm

2

cross section).

Fig. A shows the number of connections and section for a 100m length of

power supply cables; for greater lengths, calculate the section for the true

automation load. When the auxiliary connections exceed 50 metre lengths

or go through critical disturbance areas, it is recommended to decouple the

control and safety devices by means of suitable relays.

The main automation components are (g. A):

I) Type-approved adequately rated omnipolar circuit-breaker with

at least 3,5 mm contact opening, provided with protection against

overloads and short circuits, suitable for cutting out automation from

the mains. Place, if not al ready installed, a type-approved dierential

switch with a 0.03A threshold just before the automation system.

QR) Control panel and incorporated receiver.

S) Key selector.

AL) Blinker

M) Actuators.

A) Bar.

F) Rest fork.

CS) Electric edge.

Ft,Fr) Pair of photocells.

CF) Photocell post.

T) 1-2-4 channel transmitter.

RMM) Inductive metal mass detector.

LOOP) Mass detector loops.

11) CONNECTION (FIg. H-I)

ENGLISH

MICHELANGELO - 25

D812001 00100_03

Loading...

Loading...