SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F 56 essartS resukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni :liaM-E diehcsmeR 79824-D

Instruction Manual

BGS technic KG

Bandwirkerstr. 3

42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

Instructions

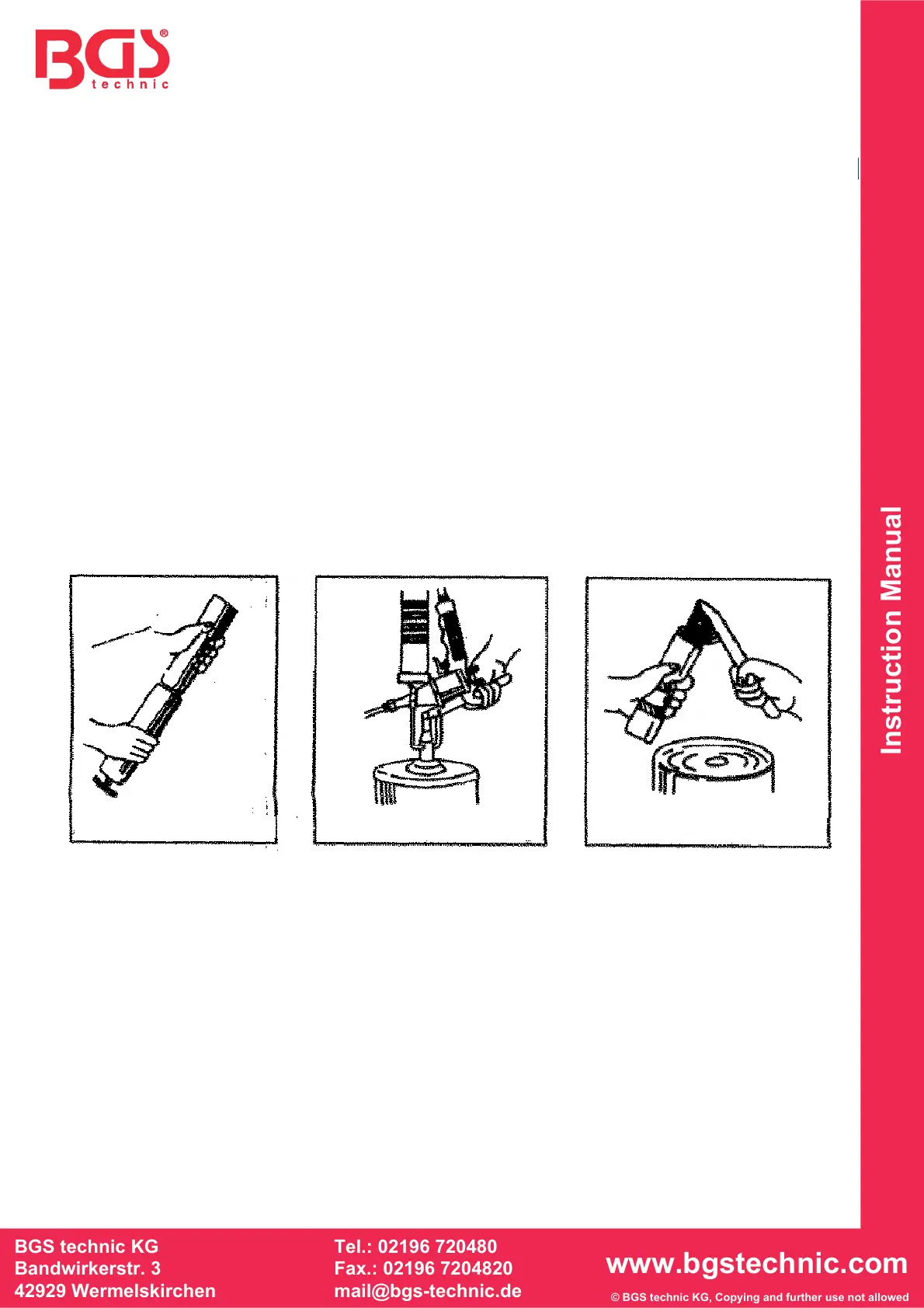

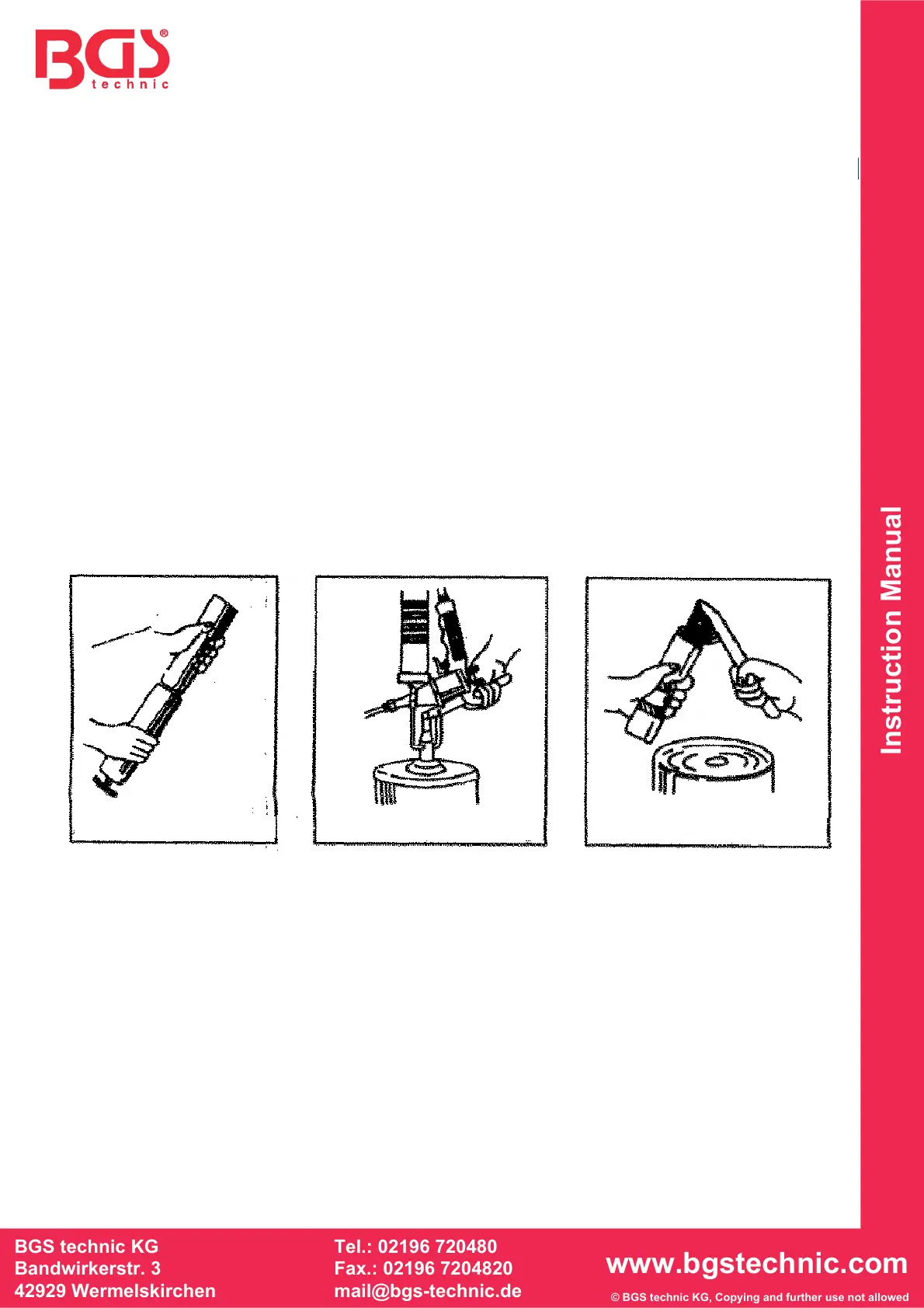

Instructions for filling the grease gun (three options)

Insert a cartridge (Fig. 2)

a. Remove the cartridge cylinder.

b. Pull back the piston completely.

c. Remove the old cartridge. Insert a new cartridge into the cylinder

d. Mount the cartridge cylinder. Press the driving plate and the piston rod back down.

Pump filling (Fig. 3)

a. Pull back the piston completely.

b. Loosen the round nozzle. Connect the filling adapter with the filling pump.

c. Now operate the filling pump.

d. Disconnect after filling the grease gun from the filling pump.

e. Press the driving plate and the piston rod back down.

Hand filling (Fig. 4)

a. Remove the cartridge cylinder.

b. Pull back the plunger completely. Fill the cartridge by hand, now with a lubricant of your choice.

c. Mount the cartridge cylinder on the grease gun. Press the driving plate and the piston back down.

The precision trigger should be kept during the entire filling.

Oil the grease gun every day or before each use.

Maintenance

Add a little oil a day through the air hose coupling in the tool.

Troubleshooting

If the grease gun does not work properly, there is probably a problem with air in the grease gun. To fix

the error, follow this instruction:

1. Remove the pipe.

2. Loosen the cartridge cylinder about one to two rotations.

3. Pull out the piston rod a few times and push them back. The excess air will pump out.

4. Press the trigger button and test whether of grease flow.

5. Repeat the above steps if necessary.

6. Tighten the cartridge cylinder again.

7. Reinstall the pipe.

8. The air is removed and the grease gun works perfectly again.

Fig.2 Fig.3 Fig.4

Loading...

Loading...