BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

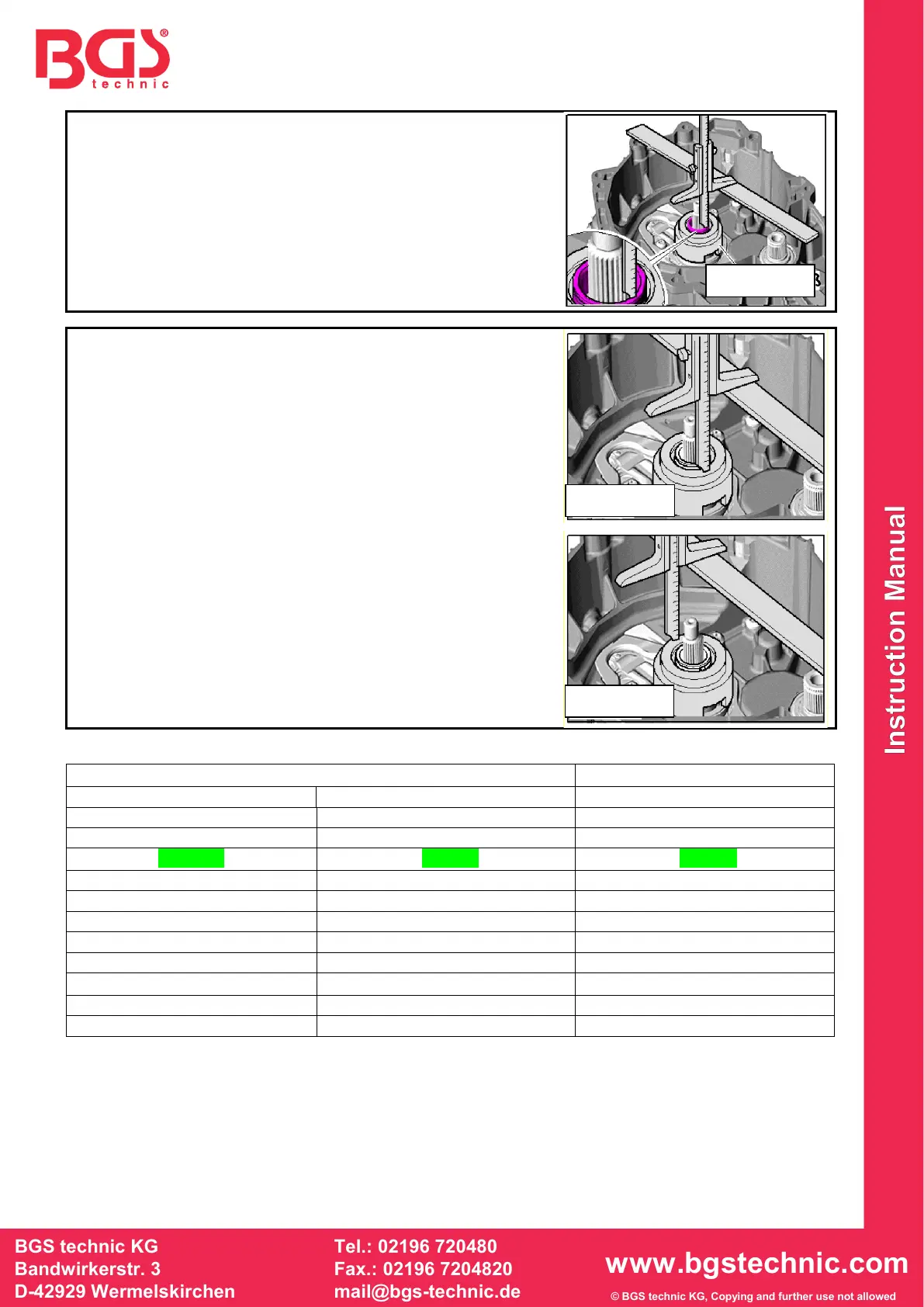

Use the depth gauge to measure down to the gear shaft.

Note down this value as (B).

Example: B = 62.3 millimeters

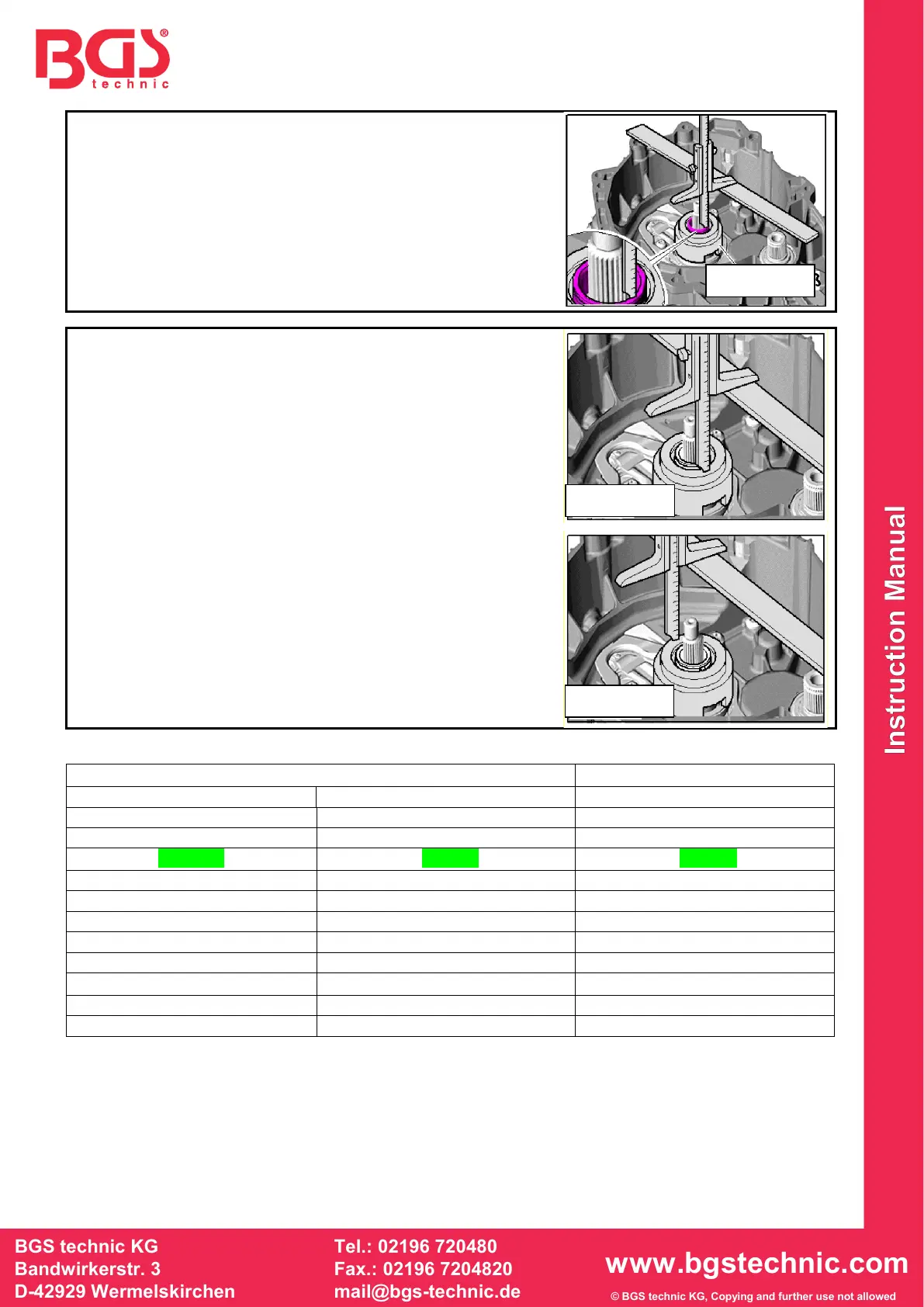

Second measurement for (K2)

Measure the distance from the ruler down to the slip gauge.

Make this measurement as precisely as possible by taking

readings from two opposite positions.

Thus, the determined value will be more precise, and any

inaccuracy caused by a „tilting“ on the engaging bearing will

be minimized.

Take the mean value of both measurements on the slip

gauge. Note down the value as (A).

Example: A= 63.5 mm

Calculate the difference of the 2 values

A - B = ?

In our example the calculation is as follows:

63.5 mm – 62.3 mm = 1.2 mm

Refer to the below table for the required thickness of the dial.

Your reading for the bearing K2

In our example we need a 1.2 mm thick dial.

Never use more than a single dial. Never place 2 dials on top of each other to reach the required

thickness.

Following this procedure, the position of the bearing K2 will be adjusted.

Loading...

Loading...