5.5. Clamping the workpieces

Clamping inserts are seated in vise jaws with play ensuring correct clamping

the workpieces. The value of play should be L = 0.2 mm with accuracy of positioning

0.01 mm. The difference between “L” dimensions in movable and fixed jaw should

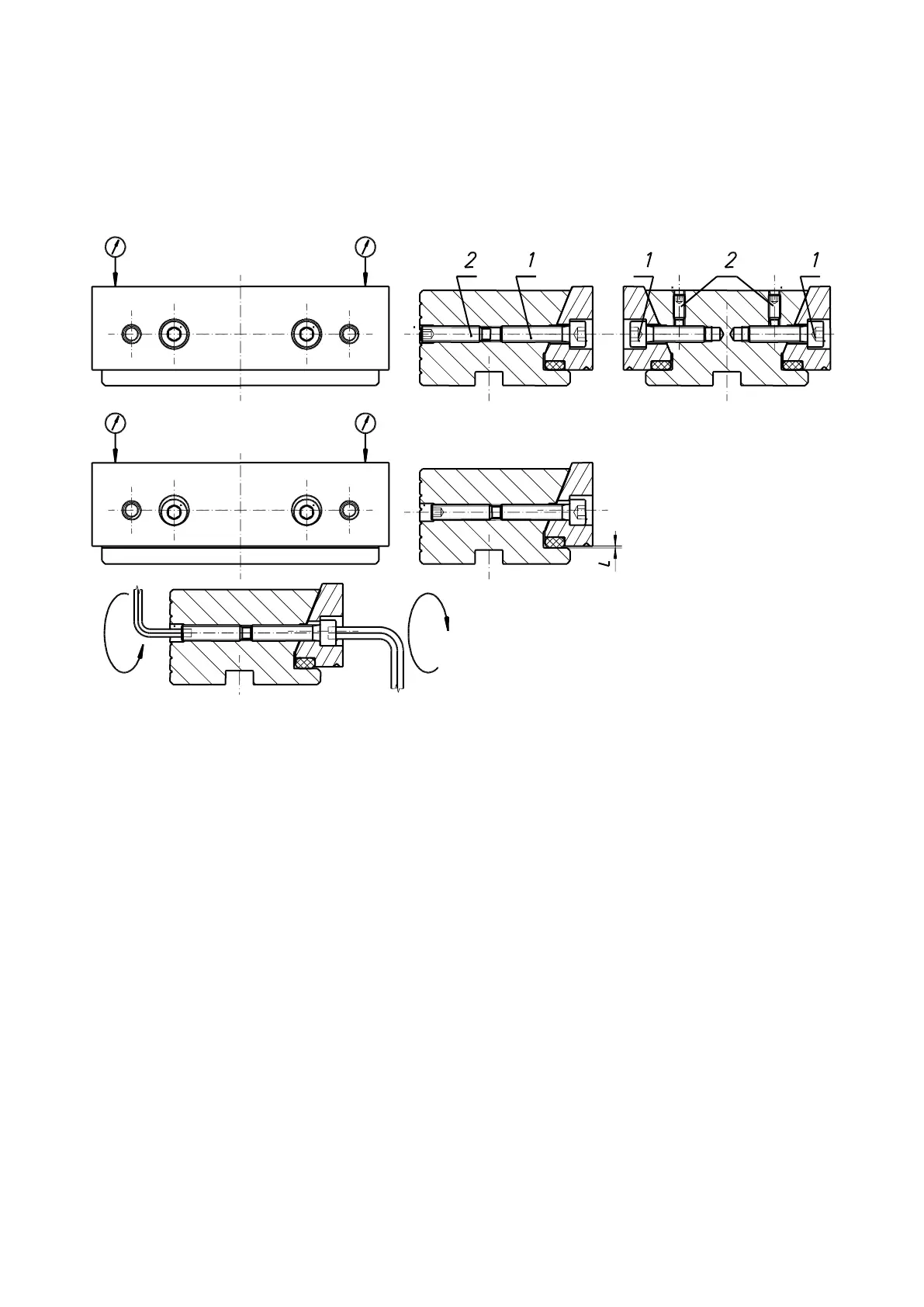

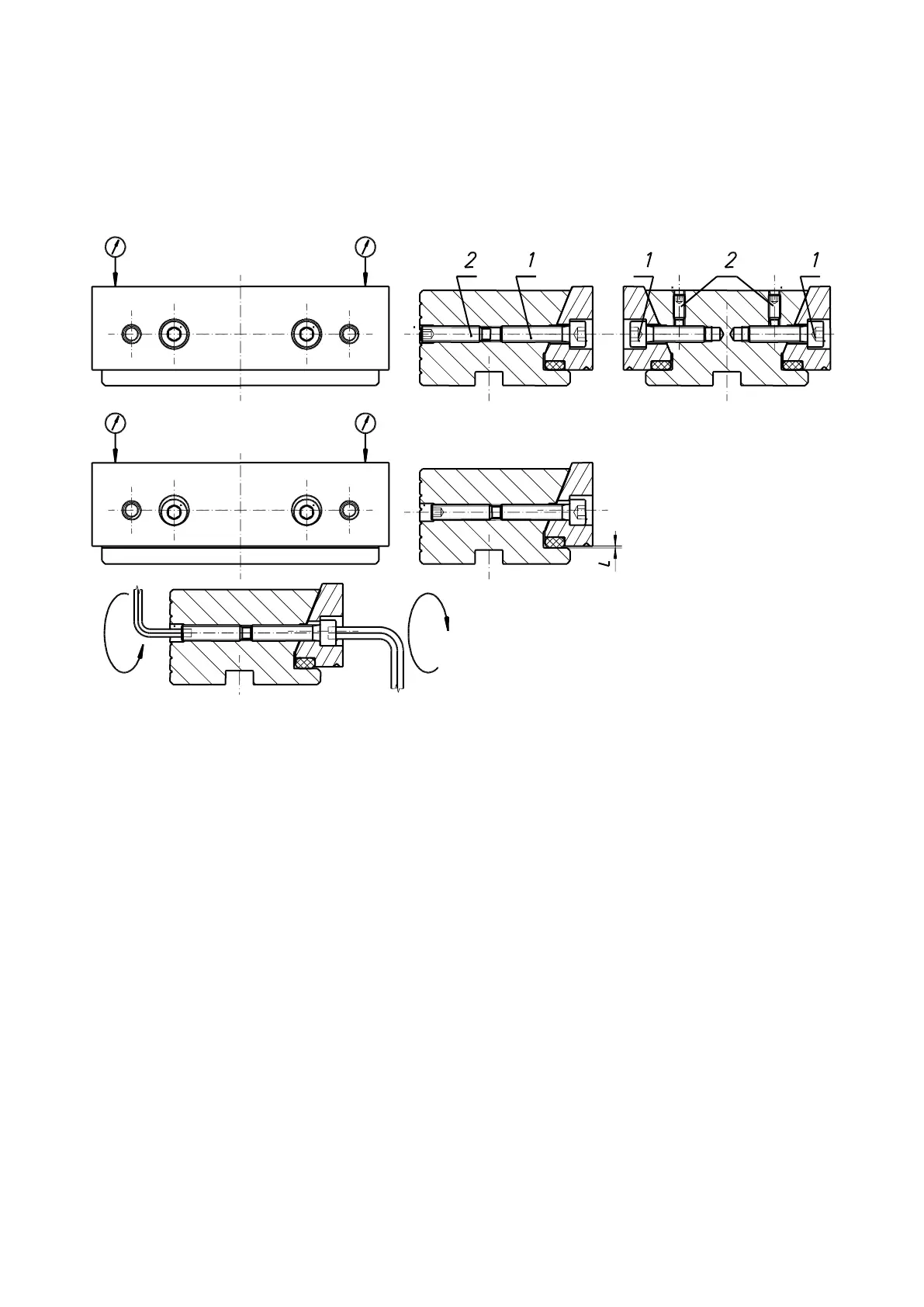

not exceed 0.01 mm. Accuracy of positioning of clamping insert is shown in Fig. 10.

Fig. 10. Accuracy of positioning of clamping insert.

To obtain the required positioning of clamping insert do as follows:

1. Loosen set screws (2).

2. Tighten the bolts (1) to make the clamping insert seat in jaw guide.

3. Check with dial gauge the parallelism of clamping insert toward the vise

base.

4. By loosing bolts (1) set required value of L = 0.2 (

0.01) mm.

5. Check with dial gauge the parallelism of clamping insert toward the vise

base, parallelism of clamping insert toward the vise base should be the same

as measured in point 3.

6. By tightening set screws (2) secure bolts (1).

Perform above steps for setting clamping inserts both in fixed jaw and movable jaw.

The proper clamping conditions is obtained when clamping inserts seat into jaw

guides. That assures the best clamping accuracy.

Loading...

Loading...